Rope Access Guidebook Sample

Rope Access Guidebook

ROPE ACCESS GENERIC WORK GUIDANCE 1

ROPE ACCESS GENERIC WORK GUIDANCE

In accordance with International Industrial

Rope Access Trade Association ICOP & ISO Standard 22846 1-2

THIS PERSONAL WORKBOOK BELONGS TO |

First name |

Lastname |

Address |

City Country |

Mobile |

IRATA No |

CHANGES TO ABOVE

SUMMARY Page

1.0 | Introduction | 4 |

2.0 | Scope | 5 |

3.0 | Anchor requirements / Rigging / Limitations | 6 |

4.0 | Anchor line management and hierarchy of measures | 13 |

5.0 | Rigging for rescue | 16 |

6.0 | Retrievable sytems | 15 |

7.0 | Hauling / Pulley systems | 17 |

8.0 | Protection of third parties and anchor area | 18 |

9.0 | On-site communication | 19 |

10. | Buddy check | 19 |

11. | Close monitoring supervision | 20 |

12. | Toolbox talk briefing | 20 |

13. | Rescue plan | 21 |

14. | Small tools | 22 |

15. | De-briefing | 22 |

16. | Incident reporting | 23 |

17. | Daily diary for L3 safety supervisor | 24 |

18. | Logging of hours worked | 25 |

19. | Suspension trauma | 27 |

20. | Work pack documentation | 28 |

21. | About risk assessment | 29 |

22. | Annex I | 30 |

23. | Annex II | 31 |

24. | Notes | 32 |

4

ROPE ACCESS GENERIC WORK GUIDANCE

ROPE ACCESS GENERIC WORK GUIDANCE

1.0 INTRODUCTION

We (company) have developed this generic method statement in accordance with IRATA and ISO guidelines.

Industrial rope access methods used at height and in confined space shall guarantee the highest possible level of protection for the technicians whilst working.

This statement is to be considered as part of an overall statement covering all access methods applicable at a site, not including those not relating to working at height.

This generic statement is valid for most of the works to be undertaken, however it should be regularly reviewed and amended by safety supervisors on site.

Should conditions of procedures change due to specific site conditions encountered during the course or the work, the site supervisor may prepare specific statements to encompass these conditions.

SCOPE AND REFERENCES

Scope

This generic method statement should provide general information to technicians engaged in rope access operations, in accordance with IRATA International Code of Practice and ISO 22846 requirements.

Out-of-scope:

This generic statement doesn’t replace the specific method statement done according to site and access specifications.

- References:

ISO | 22846-1 | ISO Personal Equipment for Protection Against Falls – Rope Access Systems Part 1: Fundamental Principles for a System of Work |

ISO | 22846-2 | Personal Equipment for Protection Against Falls – Rope Access Systems Part 2: Code of Practice |

ISO | 9001 | Quality Management Systeme Standard |

IRATA | ICOP | International Code of Practice |

IRATA | TACS | Training, Assessment and Certification Scheme |

ANCHOR REQUIREMENTS / RIGGING / LIMITATIONS

Requirements

Statement: ► Anchors should have a minimum breaking load

of 15kN and meet the EN 795-A requirements

EN 795-A

- An unquestionable structural point should have

a minimum breaking strength of 2 x 15kN = 30kN

- Eyebolts shall be torqued according to

manufacturer’s instructions

Testing (chemicals): ► Chemical anchors shall be pull tested at 5kN for

3 min with a calibrated device before first use,

and thereafter at regular intervals.

IRATA references: ICOP 2.7.9, 2.11.2, 2.11.2.6,

Annex F / TACS 6.4.2, 7.7.25

ISO 22846-2 clauses: 7.7.3

Rigging of anchor lines

Statement: ► Separate anchorages shall be used for working

and backup ropes

- A minimum of 2 points of anchorage shall be used

to anchor both the working and the backup line

- Each rope is fixed to both anchorages, via

- basic anchor

- bunny ears knot

- Y-Hang (figure of 8 + alpine butterfly).

- Each rope is fixed to both anchorages, via

- The load should be equally shared between

both anchorages

Y-hang

< 90º

Basic anchor Bunny ears anchor Y-hang

- Considering load sharing, the maximum angle

created by the ropes shall not exceed 120°

- At the work site, a maximum of 90° can be used as an easy reference point to ensure the loading at each of the anchor points remains less than the load in suspension

- 2 slings or 2 wire strops may be used on the same unquestionable structural point (e.g. H-beam)

to build a 2-rope anchor (basic anchor)

IRATA references: ICOP 1.4.2.5.3, 2.11.1.3, 1.4.2.5.1 2.11.1.2, 2.11.2.2

/ TACS 7.7.35

ISO 22846-2 clauses: 6.4.1.4 (d) (i), 7.6

Limitations

Statement: ► While using Y-hangs to anchor the ropes,

the following angles should be considered

(cf. 3.3.1):

- α < 60° very good loading of anchors

- 60° < α < 90° good loading of anchors

- 90° < α < 120° acceptable loading of anchors

(each anchor will now bear the

equivalent force of the load in

suspension)

- α > 120° NOT ACCEPTABLE

- The maximum practicable angle should not exceed 90°

- If, for some reason, it is not possible to keep

the angle < 120°, the risk assessment shall define whether a system is still safe or not, and/or where it has to be re-enforced.

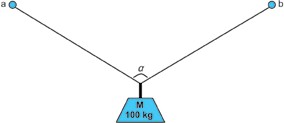

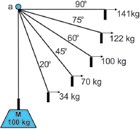

Tensioned lines:

Statement: ► For horizontal tensioned lines, the maximu

angle created by the ropes loaded in the middle should not exceed 160°

Fa,b = m/[cos(a/2)]

2

For a weight M of 100 kg and an angle α of…

α = 60° → Fa,b = 57 daN (force applied to a and b) α = 90° → Fa,b = 70 daN

α = 120° → Fa,b = 100 daN α = 130° → Fa,b = 118 daN α = 150° → Fa,b = 193 daN α = 160° → Fa,b = 288 daN α = 170° → Fa,b = 574 daN α = 178° → Fa,b = 2865 daN

IRATA references: TACS 6.4.12

ISO 22846-2 clauses: Annex D

Deviation limitations:

Deviation limitations:

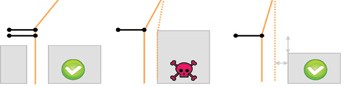

- The maximum angle for a single-anchor deviation shall not exceed 20º

- In any case, the consequences of a potential swing should be risk assessed

Statement: ► A single-anchor deviation should only be rigged if,

and in case of unique anchor failure:

- no rope friction, shock nor contact with an edge is possible

- a potential swing is not dangerous for the technician nor third parties

- the structure cannot be damaged by the resulting swing

- A double-anchor deviation should be considered

if the the system doesn’t meet the safety requiments applied to a single-anchor deviation

Use a double-anchor deviation if an anchor failure could lead to a hazardous edge contact

Do NOT rig at the edge level and keep clearance distance

IRATA references: ICOP 2.7.8.3 2, 2.11.2.10 / 11/ 19 / 21, 2.11.3.1.5,

2.11.4 / TACS 6.4.8

ISO 22846-2 clauses: Annex D

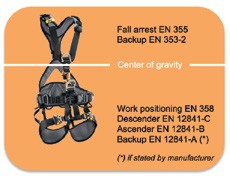

Connection to the harness

- The connecting central ring of the harness is

located below the centre of gravity and used for:

- devices connected to the working line

- cow’s tails

- positioning lanyards

- The sternal ring of the harness- sometimes marked A- is located above the centre of gravity, and shall be used for:

- backup devices (EN 353-2)

- fall arrest lanyards (EN 355)

- The dorsal D-ring sometimes marked A- shall

exclusively be used to connect:

- fall arrest lanyards (EN 355)

- The central lower D-ring of the harness

is considered an unquestionable point

- If the top part of the harness (EN-361)

is connected to the sit via a single ‘Delta’ maillon, following should be done before considering the sternal D-ring as an unquestionable point:

- The maillon should have a MBS of at least 15kN

and always be positioned in order to offer this MBS

- A mechanical unscrewing of the maillon by hand shall not be possible

- The maillon shall be torqued according to manu facturer’s recommendation

- The screw should be sealed with ‘Loctite 243’ and the plastic cover sealed with silicone in

order to avoid any accidental removal

Source: Petzl

IRATA references: TACS 6.3.5.2.3

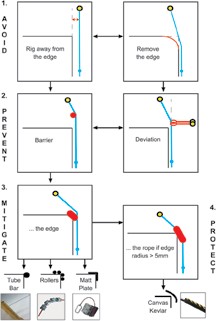

ANCHOR LINE MANAGEMENT AND HIERARCHY OF MEASURES

Hierarchy of measures

Statement: ► Rigging hierarchy:

- Avoid the hazard • Prevent the hazard

- Mitigate the hazard • Protect the rope

- Fabric rope protections should be considered as

last choice, and best manufactured in Aramid

/ Kevlar or equivalent

/ Kevlar or equivalent

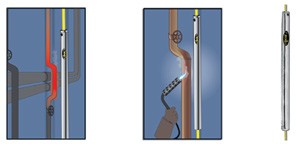

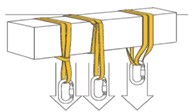

EDGE MANAGEMENT & ROPE PROTECTION HIERARCHY OF MEASURES

Mechanical protection devices

Statement: ► Rope protection devices should be selected

according to risk assessment

- Where rigging to avoid or prevent edge is not possible, pads, mats or specific construction should be used to mitigate the consequences

Rope protectors

Statement: ► For hot works, aramid/kevlar protection on each

rope should be used.

In addition, ropes should be “backed up” with wire strops

Source: Beal

- No fabric rope protection shall be used if the edge radius is < 5 mm

- Where rope protectors (eg mid-rope protection) have to be used, a thorough assessment should define whether:

- one protector for both ropes

- protector per rope

should be used. The stretch of the ropes should

also be considered

Source: Beal

IRATA references: ICOP Annex P, 2.7.10, 2.11.3.1 2.11.3.2

TACS 6.4.1(d), 6.4.6

ISO 22846-2 clauses: 6.4.2.6

RIGGING FOR RESCUE

Statement: ► As far as technically possible, ropes should be

anchored on releasable anchors to simplify a potential emergency lowering / hauling

- Best practice is to use 2 descenders of the same type

- The manufacturer’s instructions for releasable

devices should be followed at all times

Rigging for rescue shall be a priority

IRATA references: ICOP 2.2.3 (e), 2.2.5.2, 2.2.6 (h & i), 2.7.9.7, 2.11.2.22,

2.11.4 (i)(ii), 2.11.11.3

ISO 22846-2 clauses: 7.2.4 (c)

RELEASABLE AND RETRIEVABLE ACHORS

Statement: ► Retrievablea anchors should only be used when

classical method using fix and certified anchorages

are not applicable

- Rope shall always be protected, even if the structure appear to be clean and not abrasive

- Releasable anchors should only be used under

exceptional circumstances and under close supervision

While rigging a pull through, ropes shall always be protected

IRATA references: TACS 6.4.9

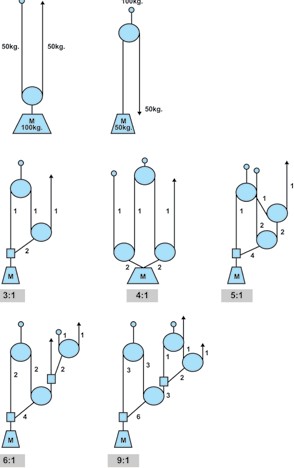

7.0 HAULING / PULLEY SYSTEMS

7.0 HAULING / PULLEY SYSTEMS

8.0 PROTECTION OF THIRD PARTIES AND ANCHORS

Third party

Statement: ► Company Inspection Services is responsible to restrict

the access to the work sites / training area and to avoid any damages to third persons

- In any case, an exclusion area should be defined and marked in order to avoid any access to unauthorized personnel, this includes following possible protective measures:

Always ensure that the exclusion area is under controlled

- Signals (exclusion zone) at groud level (barriers, cones, etc)

- Pictograms (mandatory PPE when entering site

/ venue, etc)

- No access for unauthorized persons

IRATA references: ICOP 1.4.1.1 (f), (ii) & (iv), 1.4.2.6, 2.2.4.3 (b), 2.2.6 (j),

2.11.8.2, Annex M

TACS 6.1.3.13f, 6.2.7, 7.7.11, 7.7.27

ISO 22846-2 clauses: 4.7(o), 7.7.2

Anchor protection

Statement: ► According to risk assessment, anchors should be

protected from interference

- A sentry should be posted to restrict the access

to the anchor area

IRATA references: ICOP 2.11.8.1.2, 2.11.8.2.3, 2.11.8.3

ISO 22846-2 clauses: 7.7.2.2(e)

ON-SITE COMMUNICATION

Statement: ► As far as possible, vocal communication

should be used

- Emergency signs should be practiced

![]() and understood

and understood

- If communication devices have to be used,

Communicaion devices checked and connected to the harness

a functional check shall be carried out before beginning the task

- Communication devices shall be securely

connected to the harness to avoid a potential dropping

IRATA references: ICOP 1.4.2.5.6, 2.11.9 / TACS 6.2.8.1f, 6.5.2.1b, 9.2.2

ISO 22846-2 clauses: 4.13

PRE-USE INSPECTION OF EQUIPMENT AND BUDDY CHECK

Statement: ► Buddy check and check of all suspension

equipment is part of the safety and control measures of the risk assessment

- The buddy check should be carried out exclusively

Buddy check to be done each time before going

on ropes

under L3 supervision

- Buddy checks should be recorded during the toolbox talk briefing

IRATA references: ICOP 2.11.7.4, 2.11.7.5 / TACS 6.3.3, 6.3.4, 6.3.5

ISO 22846-2 clauses: 4.12.3 (c)

CLOSE MONITORING SUPERVISION

Statement: ► Newly qualified operatives shall

- initially work under direct supervision of the rope access supervisor

- gradually be allowed to progress to working under the close supervision of an experienced

operative, at the rope access supervisor’s discretion

- The limits of the technical knowledge, as defined in the IRATA syllabus, as well as the experience of the technicians, should be considered at any time

IRATA references: ICOP 2.5.2.3, 2.5.2.4

ISO 22846-2 clauses: 5.1, 5.3 (d), 5.4.2, 5.5.2, 5.5.3.4 (g), 5.6.2

TOOLBOX TALK BRIEFING

Project briefing

Statement: ► The project briefing should be carried out by project engineer

On-site daily briefing (toolbox talk)

Statement: ► The toolbox talk briefing shall be carried out

by L3 supervisor

- The briefing by L3 supervisor is addressed

to all technicians engaged

Mandatory toolbox talk briefing at every new shift and recorded

- A toolbox talk briefing should be carried out at

every new shift, but latest every morning

- All briefings shall be recorded

- Briefings should include sharp edge management,

rescue plan and rigging for rescue

- Cf. form reference No in section 23.0

A toolbox talk record is only valid if signed by all attendees

IRATA references: ICOP 1.4.2.7, 2.2.2 (e), 2.2.4.5, 2.2.6, 2.6.2.8,

2.11.6.6, 2.11.7.2

ISO 22846-2 clauses: 4.14

ISO 9001 clauses: 7.5.1

RESCUE PLAN

Statement: ► The rescue plan shall ALWAYS be part of

the work statement

- Every rope access technician engaged on ropes

should be evacuated within a maximum of 20 minutes (to a suitable place for first aid, stretcher, medical assistance, etc…)

- A special rescue bag shoud be used wherever

rigging for rescue is not possible

- The L3 supervisor shall ensure that:

- All team members understand the rescue scenarios

- The rescue task remains within technician level of competence

- No work should be carried out without or prior to rescue plan briefing

- Cf. form reference No in section 23.0

- The L3 supervisor shall ensure that:

IRATA references: ICOP 1.4.1.1 (i), 1.4.2.7, 1.4.3.11, 2.2. 5.2, 2.2.6

(h & i), 2.11.11, 2.11.11.6, Annex B, TACS 6.2.5.1,

6.2.6, 6.2.8, 6.2.9.2, 6.5.1.2.4 6.5.1.1, 7.7.17, 9.2.2

ISO 22846-2 clauses: 4.3.2 (k), 4.6, 7.2.4 (c), 8.1.3, 8.1.5 (a) (b)

SMALL TOOLS

Statement: ► Small tools shall be connected to the harness,

to avoid being dropped to the ground.

- If not possible, they should be stored in a closable

Small tools SHALL be connected to the harness or bagged

bag attached to the harness.

- The small tool management should also deal with

instructions related to the use of mobile phone

/ camera on site

IRATA references: ICOP 2.11.8.2.2, Annex M / TACS 6.1.3.13(f), 6.2.7

ISO 22846-2 clauses: 4.11.4

DE-BRIEFING

Statement: ► The de-briefing shall be carried out at the end

of each shift

- The de-briefing shall be recorded in the toolbox

talk form in the according section

ISO 22846-2 clauses: 4.15

INCIDENT MANAGEMENT

Statement: ► Following events shall be recorded as incident,

investigated and treated as nonconformity:

- Incident

- Not working according to procedure

- Working out-of-scope

- Accident

- Near miss

- Equipment misuse

- Incidents shall be communicated without delay

to the line management

- Incidents shall be recorded and investigated

according to Companies Inspection Services procedure

- Investigation results and proposal of corrective action shall be communicated to the line management

- IRATA Form 021R shall be completed

and sent to IRATA admin

- Cf. form reference No in section 23.0

IRATA references: ICOP 2.26(f), 2.10.1.6, 2.11.12

ISO 22846-2 clauses: 4.7(f)

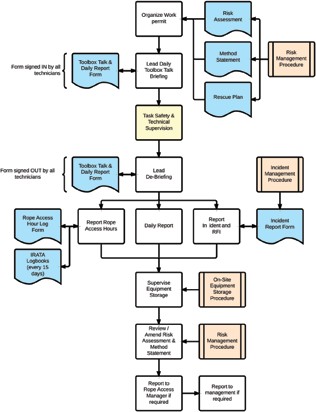

DAILY DIARY FOR L3 SAFETY SUPERVISOR

SIRATA references: ICOP 2.2.2 (f), 2.2.4.5, 2.2.6 (h & i), 2.6.2.8, 2.11.6.6,

2.11.7.2 / TACS 7.7.18

LOGGING OF HOURS WORKED

Statement: ► Working on ropes includes:

- on-site work such as

→ rigging

→ de-rigging

→ gaining access

→ protection installation

→ rescue equipment installation and preparation

→ supervision (harnessed up) on-site

→ all workers directly in support of rope access teams

- trials carried out on site such as

→ rescue practice

→ trial procedure testing

- Working off ropes on-site includes:

- site survey and inspection

- waiting for permits

- preparations prior to and post site working

- direct on-site supervision

- on-site job-related meetings such as tool box talks

- preparatory work on site

- any directly related work associated with

- Working off ropes on-site includes:

the work or job on site.

- pre-use and post-use equipment inspections

- down time because of weather

- use of IRATA qualified personnel working

where rope use is not the primary support element

(e.g. working offcradlesand scaffolds)

- where IRATA qualified personnel are in attendance

at the work site in support roles (winch operators,

communications etc) but who are not harnessed (for rescue duty).

Excludes unqualified support workers/supervisors who have no control or direct

involvement in rope access.

- Other includes:

- any time spent not covered by any other category such as

→ travel time

- relevant admin support hours from head office

which is directly related to rope access such as

→ risk assessment

→ method statement preparation

→ equipment procurement and inspection

- Cf. form reference No in section 23.0

LOGBOOK ENTRIES (Hours worked)

Should be an accurate reflection of the time spend carrying out rope access, including normal requirements such as pre-work requirements (toobox talk briefing), pre-work equipment inspection, rigging, de-rigging and training. Working with fall arrest methods

is of relevance only if used in combination with rope access

IRATA references: TACS 4.13, 4.14

ISO 22846-2 clauses: 4.17

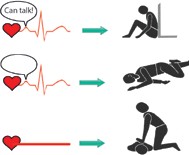

- SUSPENSION INTOLERANCE (SUSPENSION TRAUMA)

Statement: ► The suspension trauma is a breakdown of the

normal blood circulation caused by the free, immobile suspension in a harness

- The leg loops can squeeze the veins together

and thus prevent the blood circulation back to the heart

- As the resistance below the feet is missing the

so-called muscle pump can no longer be effective

for the delivery of the venous reverse flow.

Thus big amounts of blood can remain in the veins of the legs and the blood circulation is not provided with enough blood. Vital organs as brain, heart and lungs are not sufficiently supplied.

- The injured person should be removed as fast as

possible from the hanging position

- The most frequent complication after a long hanging period is the right heart part failure, also called “rescue death”, and caused by the classic shock positioning

IRATA references: ICOP Annex G

ISO 22846-2 clauses: 8.2, Annex E

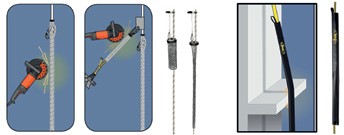

WORKPACK DOCUMENTATION

Statement: ► The outgoing work pack should at least contain:

- IRATA L3 On-Site Obligation Flowchart

- Rope access procedure

- Personnel files

- Equipment manifest

- Equipment technical notices

- Client’s details

- Project information

- Risk assessment (generic & specific)

- Method statement (generic & specific)

- Specific work instruction

- Blank forms:

→ Toolbox talk briefing

→ Daily report

→ Rescue plan

→ Hour log

→ Incident report

- The returning work pack should at least contain:

- Rope access procedure

- Personnel files

- Equipment manifest

- Equipment technical notices

- Client’s details

- Project information

- Risk assessment (generic & specific), amended if required

- Method statement (generic & specific), amended if required

- Specific work instruction

- Records:

- The returning work pack should at least contain:

→ Toolbox talk briefings

→ Daily reports

→ Rescue plans

→ Hour logs

→ Incident reports

→ Work permits (if applicable)

IRATA references: ICOP Annex N

ISO 22846-2 clauses: 4.18

ABOUT RISK ASSESSMENT

Potential hazard Hazardous situation (a person and a potential hazard

Potential hazard Hazardous situation (a person and a potential hazard

are brought together) …

. … Consequence (result of incident) …. Incident (occurence) ….

Follow the 5 steps while amending a risk assessment:

- Step 1: Identify the hazards

- Step 2: Decide who might be harmed and how

- Step 3: Evaluate the risks and decide on precautions

- Step 4: Record your findings and implement them

- Step 5: Review your assessment and update if necessary

IRATA references: ICOP 1.4.1.1 (i),1.4.2.1, 1.4.2.7, 2.2, 2.11.11, 2.11.11.5,

Annex A, Annex B, TACS 4.4.2, 6.2.3, 6.2.4, 6.2.5, 6.2.8,

6.5.1.1, 7.7.13/14/17 9.2.1

ISO 22846-2 clauses: 4.3.2(f), 4.4, 4.5

ANNEX I

- Correct use of connectors

- Correct coiling of rope

- Lark head

– 30% – 60% + 100%

Example for a 22 kN sling: 15 kN 8.8 kN 44 kN

Source: Petzl

Source: Petzl

ANNEX II: REFERRED DOCUMENTS AND FORMS

Document | Reference |

Rope access procedure | |

Rope access rescue procedure | |

Quality and procedure manual | |

Incident management procedure | |

Document | Reference |

Toolbox talk | |

Rope access rescue procedure | |

Risk assessment | |

Nonconformity report | |

Request for improvement | |

Download Link for Logged in Members: https://ndtinspect.com/?attachment=4907&document_type=document&download_document_file=1&document_file=31

Deviation limitations:

Deviation limitations: 7.0 HAULING / PULLEY SYSTEMS

7.0 HAULING / PULLEY SYSTEMS

Responses