Rope Access Rescue

Rope Access Rescue

Table of Contents

RECREATIONAL AND COMMERCIAL ROPE USES 4

INTERNATIONAL SYSTEM OF UNITS (SI) 7

STATIC VERSUS DYNAMIC ROPES 12

PERSONAL PROTECTIVE EQUIPMENT 16

THE QUALITIES OF A RESCUE KNOT 26

COMPONENTS OF AN ANCHOR SYSTEM 31

CHANGE OF DIRECTION ANCHORS (COD) 35

MINIMUM STANDARD OF A BELAY SYSTEM 38

COMPONENTS OF A BELAY SYSTEM 39

TANDEM PRUSIK AS A BELAY DEVICE 39

RAPPELLING COMMANDS AND SAFETY CHECK 49

Chapter1

Introduction to Rope Rescue

OBJEC T IV E S

- Identify the high angle environment

- Discuss why NFPA 1983 was developed and its importance

- Define the three tiered response system

- Compare the Metric system of measurements to the English

Humans have always challenged themselves to conquer their environment. The mountaineering environment has long been a quest where humans have been able to

Three important considerations in rope rescue are gravity, the human factor, and friction

conquer due to advances in equipment and techniques. The main enemy to humans in this environment is gravity. Gravity is force of attraction between all masses in the universe, or the natural force that causes objects to move or tend to move towards the center of the Earth. There are several ways that humans operate in the high angle environment, depending primarily on their objective.

Mountaineering combines a number of skills, including climbing, camping, and snow and ice travel. People engaging in mountaineering often have a goal to endure weather and obstacles to reach the summit of a mountain under the harshest of conditions.

Also known as rock climbing, this is a specialized sport that may involve the ascent of smaller formations of rock, ice or a combination of terrain. Climbers may practice this sport by top roping, or running the rope through a carabineer at the top of the climb to the bottom. There a safety person, or belayer, controls the other end of the rope that is attached to the climber. In lead climbing the climber starts with the rope at the bottom, and then ascends, placing rock anchoring hardware, or protection, into the rock. Carabineers are then clipped into the protection, allowing the climber and the rope to move up. Free climbing is practiced by climbing without safety equipment such as rope

and protection. The climber is attached to rope that is anchored in a similar fashion as top roping. The rope is designed with a great deal of stretch to absorb the shock of a fall.

Vertical caving is a sport that includes rope use as a means of descending and ascending a rope as a means to access the cave environment. This is a specialized sport that uses single rope technique (SRT). The rope is not intended as a means of protection, but as a descent and ascending device.

Commercial/Industrial Rope Uses

Rope access is growing in popularity in the commercial application of mountaineering and caving techniques to access work sites. Examples of access industries include:

Rope access is growing in popularity in the commercial application of mountaineering and caving techniques to access work sites. Examples of access industries include:

-

- Window cleaners

- Arborists

- Bridge and building inspectors

- Tower repair

- Specialized construction

Tactical operations performed by local or federal law enforcement agencies can use

equipment and techniques adapted for the specific needs of these operations. The military also conducts operations with the use of rope entry techniques.

equipment and techniques adapted for the specific needs of these operations. The military also conducts operations with the use of rope entry techniques.

Other examples of commercial/industrial rope use includes, but certainly not limited to:

-

-

- Forest Service

- Theatrical

- Motion Picture Industry

-

Rope Rescue

Rope rescue was originally practiced by fellow climbers or bystanders using the standard mountaineering equipment and techniques. Over time, these methods have been replaced by specialized rescue teams, and equipment designed specifically

NFPA 1983 defined

a one person load as 300 pounds.

This was thought to be an average weight of a fire fighter with full gear, and allowed for some margin of error.

for rescue purposes. Different terms have been used for this type of rescue, including vertical rescue, technical rescue and high angle rescue. High Angle is defined as a very steep environment in which a person is primarily supported by the rope system. One or more ropes are necessary to prevent the person from falling. This type of rescue should be considered a last resort, and used only when all other methods have been exhausted.

Fire Service Rescue

Rope has long played an important part in the fire service for utility purposes. Firefighters have also used it for life safety purposes. On June 27th, 1980, a fire

on the seventh floor of an apartment complex in New York City quickly spread to an upper floor, trapping two firefighters. Crews attempted a rescue by using a ½” nylon rope. The two firefighters with a combined weight of 440 pounds were attached to the rope it suddenly failed, sending both firefighters to their death.

NFPA 1983

Standard on Fire Service Life Safety Rope and System Components

The New York City incident spurred the development of NFPA 1983, Standard on Fire Service Life Safety Rope and System Components. Prior to this there was no recognized standard for rope rescue. NFPA 1983 helped to standardize many facets of the rope rescue discipline for the fire service community. Common terminology, equipment design, construction standards, and performance requirements are all components of the standard. The standard addressed the safety factor required for rope rescue systems. This will be discussed more in Chapter 2.

NFPA 1006

Standard for Rescue Technician Professional Qualifications The first edition of NFPA 1006 was approved on January 17th, 2003. It addresses general job performance requirements for a rescue technician as well as specific job

performance requirements for special rescue operations. Rescuers should some management and assessment skills for establishing and controlling a rope rescue scene.

The standard emphasizes a three tiered response of awareness, operations, and technician. At the awareness level, and at the completion of a recognized course, the student should be capable of recognizing conditions requiring rope rescue and making appropriate notifications to begin the rescue process.

An operations level rescuer should be capable of recognizing hazards, equipment use, and the techniques necessary to operate at a range of rope rescue incidents.

At the highest level, the technician should be capable in recognizing hazards, equipment use, and techniques necessary to operate and supervise at all rope rescue incidents.

NFPA 1670

Operations and Training for Technical Search and Rescue Incidents, 2004 Edition

Similar to NFPA 1006, NFPA 1670 identifies the three tiered response concept. The authority having jurisdiction (AHJ) must ensure that all the rescuers that respond to a technical rescue incident shall be capable of identifying hazards and notify the next higher level of response when needed. The AHJ must evaluate its training program to determine whether the current training has prepared the organization to function at the established operational level under abnormal weather conditions, extremely hazardous operational conditions and other difficult situations.

Continual training and skills maintenance is paramount for a rescue team to stay proficient in the disciple. Applicable NFPA training standards should be adhered to ensure proficiency. Rope rescue can be physically demanding, rescuers must be physically and mentally prepared and be aware of “red flags”.

International System of Units (SI)

In the discipline of rope rescue precise terms of measurement require the distinction between weight and mass. In the study of physics there are four fundamentals:

| FUNDAMENTAL | ENGLI S H | METRIC (SI ) |

| Time | Second | Second |

| Length | Foot | Meter |

| Mass | Pound | Kilogram |

Force Slugs Newton

Mass is the measure of a body’s resistance to acceleration; the mass of a body is different from, but proportional to its weight.

Force is what is required to accelerate a mass. An accurate measurement of force is the Newton (N). A Newton is the unit of force required to accelerate a mass of 1 kilogram 1 meter

To better understand force, it is necessary to express it mathematically as:

Force = Mass x Acceleration (F=MA)

Whereas mass is expressed in kilograms:

1 kilogram (kg) = 2.2 lbs

100 kg = 224 lbs, or average rescuer weight with gear

Acceleration is based on the gravity on Earth, or 10m/second² (SI)

F = MA

F = (100kg) (10m/s²) F = (1000kg) (1m/s²)

Recall that 1N = (1kg) (1m/s²)

F = 1000N F = 1kN

The equipment used in rope rescue that is tested is given values expressed in kilonewtons.

All ratings and calculations in this manual will be based the SI measurements of force.

Chapter2

OBJEC T IV E S

- Define the Kilonewton as a measurement of force

- Identify the different materials used in rope

- Identify the different rope construction types

- Discuss the different elongation characteristics of rope

Nylon may lose 10% to 15% of its strength when wet

Rope Materials

Rope has been used as a tool by early humans for survival. Naturally occurring ropes, such as vines, were the beginning of rope evolution. Early forms of man maid rope were natural fibers braided together to create a primitive rope. Unfortunately, natural rope is subject to deterioration and rotting. This forced humans to find an alternative to natural rope fibers.

Nylon was first produced by the DuPont Company in 1938. This revolutionary product proved to be useful in the military’s need for rope during WWII. Nylon proved to be a strong and reliable rope. In the years after the war, nylon was in short supply; however the increased demand for it spurred advancement in rope technology and construction. All though many materials have been introduced such as polyester, Kevlar, and polyethylene, today, nylon rope is believed to be the standard for rescue ropes.

- Nylon ropes are approximately 10% stronger than polyester ropes when dry

- They have good shock loading capabilities, with a 15-28% elongation at breaking point

- Nylon has a melting point of 480 degree F, and a high temperature working limit of 250 degree F

- Nylon has good chemical resistant to alkalis

Rope Construction

The earliest form of construction of rope was laid construction. These ropes consist of bundles of fibers, called strands, which are twisted or laid around one another. Due to

its construction, the rope’s fibers would be seriously damaged when the climber was suspended in free space and began to spin.

Plaited

Plaited rope usually consists of fibers that are plaited together, two strands side by side, taking on a square sided appearance. The advantage of this type of construction is that the rope is pliable, and knots are easily tied in the rope. The disadvantage is that this type of rope is subject to more snagging and is less abrasion resistant.

Braided

Braided rope is constructed in two manners, the solid, or single, braid and the hollow braid. The solid braid rope is constructed entirely of a single weave of three or more fibers. The disadvantage of this type of construction is that the load supporting fibers are exposed and subject to abrasion. Hollow braided rope is constructed with filler

strength of rope will vary greatly from manufactures rating and real world application

fibers, such as yarn or filament plastic, in the center. Both types of braided rope are inexpensive hardware store ropes and should not be used for rescue rope.

Double Braided

A double braided rope is essentially a braided solid rope, covered by a hollow braided rope. One rope acts as the core, and the other as a protective sheath.

The advantages of this type of construction are that the rope is soft and flexible. The disadvantage is that the core is subject to damage by dirt and grit, and the rope is susceptible to abrasion. The sheath also tends to slip down on the core.

The term kernmantle comes from the German word meaning kern (core) and mantle (sheath or covering). This design consists of a central core of fibers that support the major portion of the load on the rope. The mantle is a tightly woven sheath of fibers that supports a smaller portion of the load. The sheath protects the core of the rope from abrasion, dirt and sunlight. This type of rope is known for its strength, durability, and ease of tying knots.

Rope Design and Testing

Synthetic ropes have tremendous strength relative to their size. It is important to match the strength of the rope to the application. For the sake of safety, rope is designed to have a minimum breaking strength (mbs) that well exceeds the intended operating force; this is referred to as the safety factor. Many laws and standards put forth by agencies such as the American National Safety Institute (ANSI), NIOSH, and other industrial agencies find a 5:1 safety factor acceptable.

The number one cause of rope failure is inadequate edge protection

Some mountain and cave rescue groups find a 7:1 or 10:1 safety factor available. In the wake of the FDNY FF deaths in 1980 the writers of NFPA 1983 pushed for a 15:1 safety factor for rope systems. This means that for a two person NFPA load of 600 pounds x 15 safety margin= 9,000 lb (40kN) mbs of rope. To achieve the strength of rope, rescue teams had to use ½” or 12.7mm rope.

Breaking strength is determined by using a machine that pulls two cylinders apart at a predetermined rate. The breaking points of various samples of ropes are recorded, and an average rating is given to the rope. These tests are carried out under the standards set forth by the Cordage Institute’s standard CI 1801. NFPA 1983 refers to this standard for manufacturing design specifications.

For the purpose of this course we will use a 10:1 safety factor

| R O P E | S T R E N G H T S | ||||

| Size | Type | Strength | |||

|

Static | 30kN | |||

|

Static | 40kN | |||

Static versus Dynamic Ropes

All ropes have elongation properties or the amount of stretch of the rope at a given load. Generally ropes are designed and manufactured with three different types of elongation characteristics

Static kernmantle generally has an elongation property of less than 6% at 10% of its rated minimum breaking strength (mbs). This type of rope is a good choice for general rescue operations, including lowering and raising operations due to its minimal “creep”.

Low stretch kernmantle must be between 6 to10% elongation at 10% of its rated minimum breaking strength. This type of rope is common in Europe.

Dynamic kernmantle is designed for impact absorption. Most often it is used for lead climbing, dynamic rope has high elongation characteristics and is good for absorbing energy during a fall. This rope is usually manufactured to meet the designed of climbing sport organizations. The elongation properties vary by design and manufacturer; some are designed to have a 60% elongation before breaking. This type of rope may not meet NFPA 1983 equipment manufacturing standards.

Webbing

Most webbing is made from either nylon or polyester and has the same characteristics as in rope manufacturing. Webbing may be preferred over rope for anchors or for harnesses. It has less elongation than rope, so more load be transferred to the anchor or equipment. Webbing is less expensive than rope and has a flat surface that may be more abrasion resistant than rope in certain applications.

There are two types of webbing, flat and tubular. Traditionally, tubular webbing was stronger than flat webbing. However, many manufactures are producing flat webbing that is stronger than the traditional tubular webbing.

W E B B I N G S T R E N G H T S

| Size | Type | Strength | ||

|

Tubular | 18kN/4,000lbf | ||

|

Flat | 26kN/6,000lbf |

Accessory Cord

Accessory cord is smaller diameter rope used for a variety of tasks for which regular rope would be too bulky. Most accessory cord is soft and more flexible making it easier to tie knots, and it grips well when used in friction knots such as Prusik hitches. Accessory cord is usually found in sizes up to 9mm.

A C C E S S O R Y C O R D S T R E N G H T S

Size Strength

-

- 6mm 6.8kN/1550lbf

- 7mm 10kN/2100lbf

- 8mm 14kN/3150

The number one cause of rope failure is

inadequate edge

Care of Ropes

Even with advancements in design and testing of rescue rope, the reliability and life span of it will depend on how well it is cared for.

Abrasion

Abrasion is one of ropes greatest enemies. Minimizing abrasion can ensure a safe and effective operation. Abrasion is caused by rope running over the edge of a building or rock face. It can be compounded by “bouncy” rappelling or swaying on the part of the rescuer. Following are methods of protecting rope from abrasion:

protection ■ Rope pads made from canvas, fire hose, packs, blankets, etc.

-

-

- Commercial devices such as metal edge rollers, roof rollers and flexible nylon pads

-

- Reduce bouncy rappels and hauls

The original addition of NFPA 1983

Rope History Log

Each rope must have its own log with the pertinent information on the manufacturer, diameter, design, tensile strength, date of purchase, and length. The ropes need to be marked with a rope tag, in order to distinguish it from other ropes of the same color. It is essential that entries are made for a rope each time it is used into the rope log. Log entries should include if any damage was sustained and the type of operation the rope was used in.

Storing Ropes

The proper storage of rope is essential in protecting the rope from damage. Rope should not be stored in direct sunlight, away from vehicle exhaust and battery fumes. Additionally, rope should not be stored to, or exposed to, wet or damp conditions, and not be allowed to be contaminated with dirt and grit.

Bagging Ropes

One of the most convenient ways of storing, transporting, and protecting rope is called bagging. A bagged rope is also easily deployed. To bag a rope start with the end of the rope, and run it through a carabiner or tight against the top of the bag

recommended that

life safety rope be used only once, then destroyed

then “stuffing” it into the bag.

Inspecting Ropes

Ropes inspection is an ongoing process that should be performed before, during and after rope use. Rope should be inspected by look and by feel. When visually

inspecting the rope look for the following:

-

- Discoloration: This could indicate chemical or sunlight damage

- Glossy marks: May be a result of heat damage

- Exposed core fibers: These should be white in color on most ropes

- Variance in size and diameter or soft spots: This may indicate core damage

- Contamination with dirt, grit or chemicals

Eventually, ropes will need to be cleaned. The most important rule to follow is to follow manufactures recommendations for cleaning. Ropes can become damaged by dirt and debris being forced into the core of the rope. Ropes can also be damaged by stepping on them. A general rule of thumb is to never step on rope, it can force even more debris into the core. Metal particles may also be forced into the rope as it runs through hardware, such as rappel devices.

There are commercially made rope washing devices that use jets of water to wash the rope as it is ran through a tube. Another option is to wash the rope in a washing machine. The following are recommendations for washing rope in a washing machine:

- Coil the rope in an accepted coil, such as the chain coil, place in a mesh bag to prevent tangling on the agitator

- Use gentle soaps that are safe for synthetics, these are most likely safe for cleaning rope; do not use bleach

- Use cold water setting

- Air dry only out of direct sunlight; do not use a clothes dryer

- Webbing can be cleaned for in the same manner

Chapter3

Gloves that have been contaminated with oil, products of fire and that are dirty should not be used for rope rescue work

Personal Protective Equipment

OBJEC T IV E S

- Identify the different classes of harnesses per NFPA 1983

- Identify proper helmet use for rope rescue

- Review other personal protective equipment used in rope rescue

Personal Equipment

Helmet

The helmet is a vital piece of equipment that the rescuer uses. It can protect the wearer from injury or reduce the severity of injury from falling debris such as rocks or climbing hardware.

The helmet should be designed to be used in a rope rescue setting by being impact resistant and to adsorb impact. Construction type helmets, motorcycle and bicycle helmets are not suitable for the rope rescue environment. The helmet should be equipped with a three point harness; single or elastic harnesses may not be secure enough and fall off of the rescuer while in use and should be avoided.

NFPA 1951, Standard on Protective Ensemble for USAR Operations specifies types of helmets used in urban search and rescue and may be a good resource for selecting a proper helmet.

Gloves

Gloves are used in rope rescue to protect the hands against burns and abrasions from running ropes. Gloves should be light enough to enable the rescuer to maintain a sense of feel of the rope. Soft leather gloves can be used in rope rescue, however commercial versions are available.

Ladder belts are designed only to prevent falls from a ladder and are not intended for the rope rescue environment

Harnesses

NFPA 1983, Standard on Fire Service Life Safety Rope and System Components

This standard classifies harnesses into three classes:

Class I

A light duty harness meant for light duty work and emergency egress by one person with a design load of 1.33 kN.

Class II

A seat harness that secures around waist and around thighs or under buttocks and designed for one person, or when another person’s weight may be transferred to the harness during the course of a rescue. The harness is designed for a 2.67 kN, two person load.

A full body harness designed for rescue loads, fall protection and for rescues in which inversion may occur. A class III harness fastens around the waist, around thighs or under buttocks, and over the shoulders with a design load of 2.67 kN.

Improvised harnesses can be made from webbing and used when a commercial harness is not available.

A Swiss seat is a seat harness that can be formed using 20 to 25 feet of webbing and

should be used only when a commercial harness is not available and time is of the essence. All improvised harnesses should be preloaded prior to operations to ensure a proper harness fit and security.

should be used only when a commercial harness is not available and time is of the essence. All improvised harnesses should be preloaded prior to operations to ensure a proper harness fit and security.

A properly tied Swiss Seat harness

A hasty chest harness can also be tied out of webbing and is useful when a commercial chest harness or Class III harness is not available. It may be preferred in some cases to commercial chest harnesses due to it being lighter and less expensive.

1. Start with a length of webbing with an overhand tied in the middle, forming a bight

2. Place the bight on the upper middle portion of the sternum, placing one end of the webbing over the right shoulder

3. Take the other end of the webbing and place it under the arm, around the back and under the left armpit

4. Bring the end of the webbing that was placed over the right shoulder over the left shoulder. The webbing should cross over the webbing that was placed under the armpits.

5. Pass the end of the webbing from under the left armpit through the bight on the chest.

6. Tie a half-hitch and an overhand knot tight against the bight.

7. Take the webbing that was placed over the left shoulder and tie it to the other end of the webbing with a water bend or square knot.

8. To connect chest harness to seat harness, pass a short section of webbing through the bight on the chest harness and through where the “D” ring attaches to the seat harness.

Completed hasty chest harness with seat attachment.

Chapter4

Hardware and Software

OBJEC T IV E S

-

- Identify the different types of hardware used in rope rescue

- Identify the care and inspection procedures for hardware

- Recognize the need for rope abrasion protection

Rope rescue gear can be classified as either software or hardware. Software is made from some kind of fiber, and hardware is made from some type of metal. There has been much advancement in the types of metals and alloys that are used in the construction of rope rescue hardware.

NFPA 1983

According to NFPA 1983, hardware is a type of auxiliary equipment that includes, but not limited to, ascent devices, carabiners, descent control devices, pulleys, rings and snap links. Most hardware will be marked if it meats the NFPA 1983 standard.

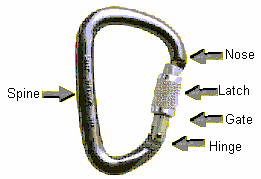

Carabiners are used to link together parts of the rope rescue system. The basic parts of the carabiner are the spine, hinge, gate,

Carabiners are used to link together parts of the rope rescue system. The basic parts of the carabiner are the spine, hinge, gate,

nose and latch (figure 3.1). Carabiners are manufactured in a wide variety of shapes. The original design was a simple oval shape; in this design the load would be the same on the spine side and the gate side. As with any carabiner design, the weakest side is the gate side. The “D” shaped carabiner was designed to place the load on the long axis or spine

side. When a rope is clipped into the carabiner and placed under a load it would slip into position on the spine side.

Figure 3.1

21

Carabiners also come in locking and non-locking configurations. The non-locking carabiner has the potential for the gate to be opened by contact with the wall or the edge or another piece of equipment. Locking carabiners are preferred in all life safety applications. If locking carabiners are not available, two non-locking carabiners can be used with the gates opposing.

The weight of the equipment is a big concern amongst most rescuers. Carabiners can be made of either steel, aluminum or an alloy. Aluminum carabiners usually are lighter, but may not be as strong as steel. Steel carabiners are heavier but stronger than aluminum. Steel carabiners are susceptible to rusting, if using steel, make sure they are

plated, and there are stainless steel hinge springs.

Three way loading is the potentially dangerous loading of a carabiner in three axis’s

Carabiner Labeling

- CEN/UIAA system: Stamped with major axis, minor axis, and gate opened strengths in kN.

- NFPA system: Carabiners meeting NFPA 1983 standard are marked with “meets NFPA 1983, 2001 ED”. Will also have either an L or G stamped into the frame. The L indicates light use and is designed for one person loads. The G is designed for general rescue use with a minimum major

axis breaking strength of 40kN.

Descenders

Descenders are essentially descent control or friction devices. The user places the rope in the rappel device, attaches it to their harness to descend the rope at a controlled speed. There are many types and designs of descenders available. All work by applying friction to the rope to slow the travel of the rescuer.

The Figure 8 with ears, or rescue eight descender (figure 3.2) is a common piece of hardware in rope rescue. It is designed for the rope to contour around the large ring. The ears prevent the rope from slipping over the ring to form a

22

Figure 3.2

girth hitch. The larger size helps to dissipate heat better, and accommodates larger diameter rope.

A brake bar rack (figure 3.3) is a descending device that offers a great amount of control and the ability to greatly vary the amount of friction. The brake bar rack consists of two components, an inverted U-shaped frame with one leg longer than the other with an eye in which a carabiner can be clipped into. The other component is a series of bars with holes drilled through one end so the bars slide freely on the long side of the frame. On the other side the bars are notched so the end of the bar can be clipped into the short side of the frame. The rope is woven through the bars. Under tension the rope

A brake bar rack (figure 3.3) is a descending device that offers a great amount of control and the ability to greatly vary the amount of friction. The brake bar rack consists of two components, an inverted U-shaped frame with one leg longer than the other with an eye in which a carabiner can be clipped into. The other component is a series of bars with holes drilled through one end so the bars slide freely on the long side of the frame. On the other side the bars are notched so the end of the bar can be clipped into the short side of the frame. The rope is woven through the bars. Under tension the rope

Figure 3.4

holds the bars in place on the frame.

Another type of brake bar rack is

the BMS Micro-Rack (figure 3.4).

Figure 3.3

It is designed in the shape of a “U”. The rack is attached at

the inside of

U, allowing the rack

to remain

straight when loaded.

There are many descenders available on the market. It is the responsibility of the user to understand and follow operating guidelines for each piece of equipment.

Rope Grabs

Rope grabs are classified as either hard cams or soft rope grabs.

Hard cams are mechanical devices made of metal that uses a camming action to grip the rope. These devices cams have a metal conical toothed cam that grabs the rope. This design has a history of destroying the outer sheath and yielding the rope at only 4-6 Kn. Newer devices have increased surface areas with curved, convex grabs stamped into the device

Hard cams can be further classified as personal use and general use.

23

These devices are designed for a single person load for ascending rope and are not intended to be used with hauling systems where forces may be too great (figure 3.6). Personal use ascenders are generally used in pairs, with left and right handed models.

These devices are designed for a single person load for ascending rope and are not intended to be used with hauling systems where forces may be too great (figure 3.6). Personal use ascenders are generally used in pairs, with left and right handed models.

General Use Ascenders

General use ascenders are designed to be used as progress capture devices for heavier loads. These devices may perform better on

rope that may be wet, muddy, or icy. These devices may also be used as ascenders, but generally do not have handles in them like personal use ascenders.

Soft rope grabs can be webbing, rope or cordage that is formed into a hitch to grab a host rope.

Soft rope grabs can be webbing, rope or cordage that is formed into a hitch to grab a host rope.

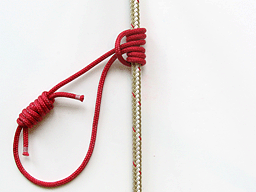

One of the most commonly used soft rope grabs is the prusik hitch (figure 3.8). The prusik was introduced by Dr. Karl Prusik, an Austrian mountaineer, as a means of ascending rope.

The prusik will grip the rope without damaging the outer sheath. Multiple testing has determined that a properly dressed prusik will “clutch and grab” at 9-13Kn for a single three wrap prusik, and 10-14Kn for tandem three wrap prusiks.

-

- Ascending or self rescue

- Progress capture device

- Belay device

- A clutching device when excessive forces are placed on the system

- Placed to take knots out of the system

Pulleys should be four times the diameter of the size host rope for maximum efficiency

Pulleys

The modern pulley is the successor of the traditional block and tackle. A pulley is designed to transfer force from the input of the pulley to the output. This is achieved by reducing friction in rope as it changes directions. The parts of the pulley are the round disk in the middle, or sheave, the sides are called side plates, and the device on which the sheave runs on is the axle (figure 3.9). The axle runs on bearings that

The modern pulley is the successor of the traditional block and tackle. A pulley is designed to transfer force from the input of the pulley to the output. This is achieved by reducing friction in rope as it changes directions. The parts of the pulley are the round disk in the middle, or sheave, the sides are called side plates, and the device on which the sheave runs on is the axle (figure 3.9). The axle runs on bearings that

are either a bronze bushing or a ball bearing. The ball bearings are more expensive, but move more freely than the bronze bushings.

Pulleys are designed as single, double or triple pulleys. In double or triple pulleys the metal plate that separates the sheaves is called the becket (figure

3.10).

Prusik Minding Pulley (PMP)

PMP’s are pulleys that are designed to “mind” prusiks as the rope travels through the pulley (3.11). This prevents the prusiks from getting “sucked”

PMP’s are pulleys that are designed to “mind” prusiks as the rope travels through the pulley (3.11). This prevents the prusiks from getting “sucked”

into the pulley. This type of pulley is a common piece of hardware for

rope rescue teams.

Kootney Carriage Pulley

The Kootney carriage pulley is a specialized pulley that is designed to be used to pass knots in the rope, as a high strength tie off adjunct, and for use on elevated track systems.

The Kootney carriage pulley is a specialized pulley that is designed to be used to pass knots in the rope, as a high strength tie off adjunct, and for use on elevated track systems.

H A R D W A R E A N D S O F T W A R E S T R E N G H T S

Strength

- Aluminum Carabiner 22-30Kn

- Steel Carabiner 40Kn

- Rescue 8 Plate 22Kn

- Brake Bar 46-56Kn (breaks rope at 26Kn)

- Tandem Prusik Clutch at 10-14Kn

- Single Prusik Clutch at 9-13Kn

- PMP 36Kn

Chapter5

OBJEC T IV E S

- Describe the qualities of a good knot

- Describe the functions of various knots

- Describe the various parts of a knot

Knots are an important part of the rope rescue system. They connect the various parts of the system together to make operations possible. It is vital for all rescuers to be able to tie knots correctly and maintain proficiency in knot tying. Knots include bends, bights and hitches.

Definitions

-

- Bend – A class of knot that joins two ropes or webbings together

- Bight- The open loop in a rope that is formed when the rope is doubled back on itself

- Hitch- A knot that attaches to or wraps around an object or rope in such a way that when the object is or rope is removed, the knot falls apart

- Safety Knot- A second knot used to secure the tail of a primary knot

The Qualities of a Rescue Knot

Rescue knots should have the following qualities:

Affects of Knots on Rope

Every knot will diminish the strength of the rope. Any sharp bend less than four times the diameter of the rope will compress the fibers and transfer an unequal load to the parts of a knot.

K N O T S T R E N G T H L O S S I N R O P E

( A V E R A G E O F O R I G I N A L S T R E N G T H )

Material Bowline Figure 8

|

74% | 78% |

|

73% | 80% |

Types of Knots

The following are examples of knots used in rope rescue operations. This manual is not intended to be a guide for knot tying. Various resources are available for knot tying instruction (see resources at the end of this manual):

-

-

- Figure eight “stopper”

Figure eight “follow through”

Figure eight “follow through”- Figure eight on a bight

- Directional figure eight on a bight

- Overhand safety

- Double overhand bend

Water bend for webbing

Water bend for webbing- Münter hitch

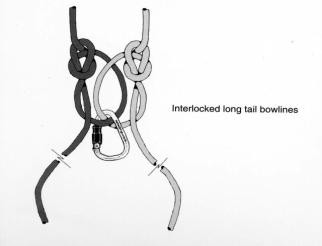

- Bowline

- Interlocked long tail bowlines

-

Chapter6

Anchors

- Describe various types of anchors

- Describe how to evaluate anchors

- Define the parts of a anchor system

- Describe anchoring techniques

An anchor that is of significant strength and can withstand high forces is considered to be “bombproof”.

As the name implies the anchor is the foundation of the rope rescue system. Anchor selection and anchoring techniques are crucial to a safe operation.

Types of Anchors

Anchors on Structures

Man made anchors are generally found on structures, but can include the following:

- Structural columns and beams

- Stairwell supports

- Large masonry walls and structures

- Anchors for window washers

- Scuppers

- Elevator housings

Natural Anchors

Natural anchors include boulders and trees, and may include shrubs and bushes. Trees should be evaluated for rot, if it’s alive or dead, and a substantial root system. Boulders should have no movement under foot and firmly embedded into the ground. Shrubs and bushes may be an alternative if no other anchor is available, and if it is used as part of an anchor system.

Improvised Anchors

Improvised anchors can be used when no other suitable anchor is available. These types of anchors include:

-

Emergency apparatus – An axle or tire may be used on a vehicle for an anchor. Lock out/tag out procedures should be followed to prevent the vehicle from being moved while in use as an anchor

Emergency apparatus – An axle or tire may be used on a vehicle for an anchor. Lock out/tag out procedures should be followed to prevent the vehicle from being moved while in use as an anchor- “Rock Protection” – These are specialized pieces of hardware that are designed for creating anchor points or “protection” in places where natural anchors are not available. Examples include:

o Nuts, chocks, cams

-

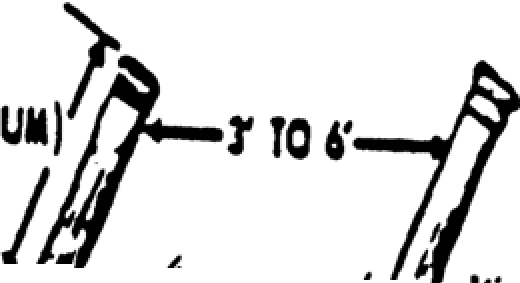

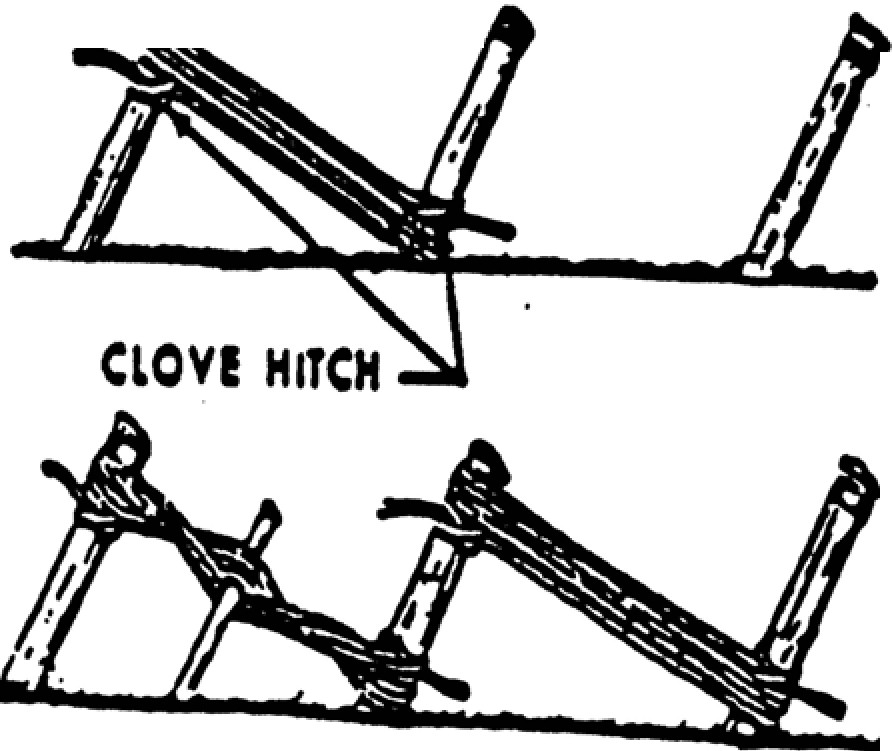

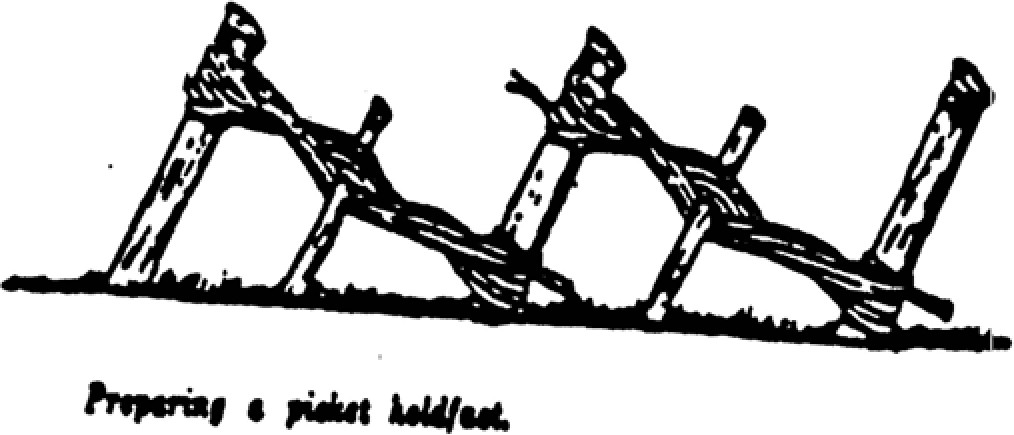

- Picket System – A picket system is a relatively strong system made out of either pickets and rope or are commercially available

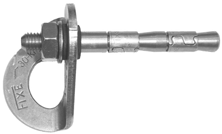

Bolts and hanger system – This is a specialized system used to install an anchor point in a wall or rock face. A hole is first drilled into the material and an expansion anchor or a bolt set in epoxy is placed. Then a hanger is attached and secured to the bolt. Bolts and hangers are generally designed

Bolts and hanger system – This is a specialized system used to install an anchor point in a wall or rock face. A hole is first drilled into the material and an expansion anchor or a bolt set in epoxy is placed. Then a hanger is attached and secured to the bolt. Bolts and hangers are generally designed

2′ (MINIM

…….

- DIRECTION

………

………

01,UU

,…

…,_

IIVI PICXITS (ntn 01 WOOD) INTO / ,, ……../,/ / /

IIVI PICXITS (ntn 01 WOOD) INTO / ,, ……../,/ / /

…

vanc.u , ,, .,…. ‘ ,’

01AMETa ,t/

.,..

GIOUNO It MINIMUM FROM

@ lASH·PICK ETS TOGITHII, STAITIHG AT TOP OP 111ST PICKET

.

4-4 TUIHS

@ TWIST IOPI WITH IACIC STICK, TH!H DIIV! STICX INTO GIOUHD

© COMPLIT!D PICICIT HOL01AST

© COMPLIT!D PICICIT HOL01AST

t/il

, r

IIIIIJJ’4t,’ PltNIMUIII

30

Evaluating Anchors

These factors should considered when evaluating anchors

-

- The condition of the anchor: A live tree is generally preferred over a dead tree. Deteriorated components on a structure should be avoided

- The strength of the anchor: Anchors of larger mass or structural in nature can generally withstand greater forces

- The location of force on the anchor point: A anchor point higher on a anchor, such as a tree, puts more stress on the anchor than a lower attachment point

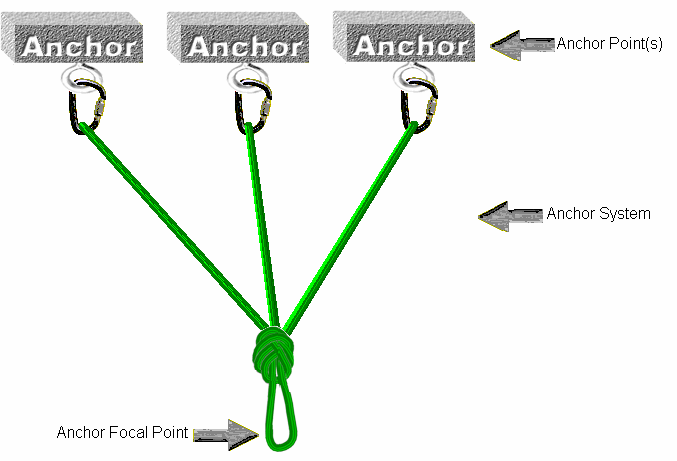

Components of an Anchor System

An anchor system is made up of the following items:

- Anchor point(s): A single or multiple anchor points may be used

- Anchor focal point:: This is where the rope rescue system, such as the belay line and main line, is attached to the anchor system

Anchor system

Anchoring Techniques

Tensionless or High Strength Tie-Off

This can be used to retain a high degree of rope strength. The anchor for this tie

should be carefully selected so not to damage the rope. The high strength tie-off

(HSTO) shall be used on objects that are at least four times the diameter of the rope and the rope shall be wrapped a minimum of three times around the

object. The wraps of the HSTO create friction around the object and do not fully

load the knot, thus reducing the strength loss of a knot in the system.

The number one cause of system failure is inadequate edge protection. Use edge protection where needed

Example of a high strength tie-off

Webbing as an Anchor

Webbing is a valuable in creating anchor systems because of its strength, size, and cost. In general, girth hitches and slings should not be used in anchors because they put potentially dangerous stress on the webbing.

Wrap Three, Pull Two

The wrap three, pull two (W3P2) is a stronger alternative to the sling or girth hitch. It is formed by wrapping three loops around the anchor securing it with a water knot and then pulling two loops out. The water knot should be on the interior loop, facing the direction of pull. The interior angle of the two loops should be approximately 30°. A wrap two, pull one (W2P1) can also be used, although it has a lower capacity.

Wrap Three, Pull Two

Load Sharing Anchors

Load sharing anchors are used when a single anchor point is not of sufficient strength to support the system.

Load sharing anchors are used when a single anchor point is not of sufficient strength to support the system.

Example of a load sharing anchor

Pre-Tension Back Tie/Front Tie

A pre-tension back tie is used as a backup anchor when the primary anchor is of questionable strength, where high anchor points are used on the primary anchor, and it is desirable to remove the slack in the line prior to operations. A pre-tension front tie may be used also to take the slack out of a system and is generally used on the belay line.

Components of a pre-tension back/front tie:

- Separate W3P2 at primary anchor with one strand interlaced with the primary anchor.

- 30m of 8mm cord or other suitable cord or lifeline

- Additional anchor point

- The pre-tension back/front tie should be no more than 15° off center of the primary anchor in either direction

Change of Direction Anchors (COD)

Definition: A rigging technique for redirecting rope rescue systems to a more desirable location or angle for a safer and more efficient operation.

COD anchor use

-

- Main anchor system not inline with direction of load to be raised or lowered.

- COD may be used to avoid abrasive edge protection problem by elevating the rigging above the edge.

- COD may be used to elevate a high anchor point above an edge to help deploy the litter over the edge during a lowering or hauling operation.

Rigging Change of Direction

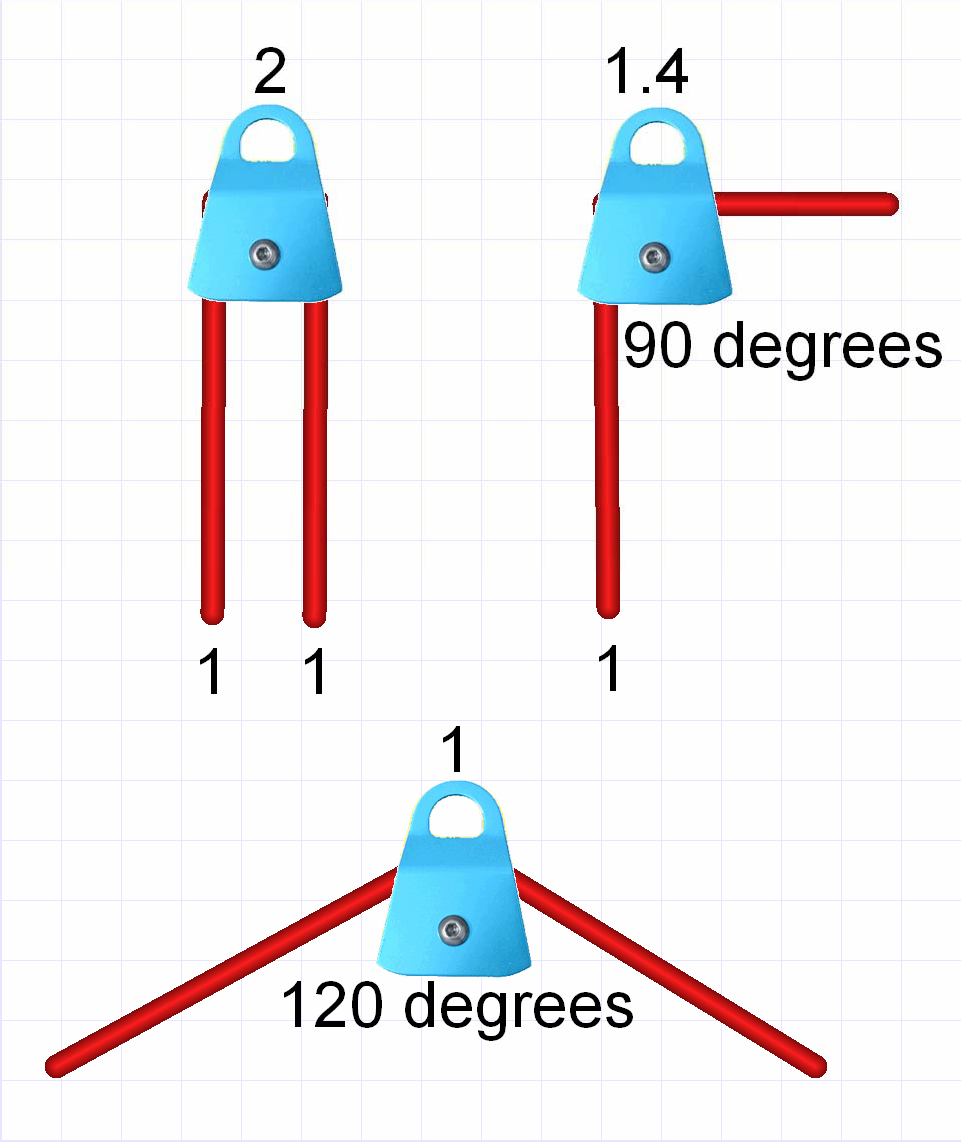

The principles and considerations of simple anchor points shall be used. The critical angle and force vectors do compromise COD anchors.

For COD anchors the critical angle and force vectors are OPPOSITE from multiple anchor point systems. The narrower the angle of the COD anchor the MORE force is put on the anchor. When the rope legs extending from a COD attachment become parallel (turned 180 degrees), twice the load is developed on the COD anchor. In effect, a 2:1 mechanical advantage (or disadvantage) has occurred.

In summary, use COD system components when necessary, just keep the angle as wide as possible from the main anchor system.

S T R E N G T H O F A N C H O R C O M P O N E N T S

Component Drop Test Breaking Strength

- 25mm Tubular Webbing 18kN

- 25mm Flat Webbing 26kN

- W2P1 Tubular 24-26 kN

- W2P1 Flat 32kN

- W3P2 Tubular 35-40kN

- W3P2 Flat 46kN

Chapter7

OBJEC T IV E S

- Define a belay system

- Describe the advantages of lower versus rappelling systems

To belay is to protect a rescuer or a load from falling if failure of the mainline or an uncontrolled descent occurs. A belay system allows for redundancy, thus increasing the safety factor in rope rescue. This can be done by using a two-rope system, one for the mainline and one for the belay line. The belay line shall never be loaded during normal operation, only during a failure of the mainline or an uncontrolled descent.

When a belay system is activated due to an uncontrolled descent or a mainline failure, greater forces are experienced throughout the belay system due to “shock loading”. Suitable anchors must be selected in order to account for these forces. Because the belay line is not under tension during normal operations, there may be stretch in the belay system before it stops the load due to the elongation properties of the rope. To minimize these, it is recommended that pre tension front ties be used in a belay system to take as much stretch out of the line as possible.

The “worst case scenario” in rope

Minimum Standard of a Belay System

From 1982-1989 the British Columbia Council of Technical Rescue (BCCTR) critically analyzed and drop tested numerous types of belay devices and established a minimum standard for belay system

rescue is to have a performance: fall of 1m with 3m

of rope in service

- With a 200kG (or 2kN) load, attached to 3m of rope in-service the belay system must be able

to:

-

- Withstand a 1m drop of the load

- Stop it in less than 1m additional travel

- The system not experience forces greater than 15kN

- Host rope must maintain at least 80% of its original strength

Components of a Belay System

The following components make up the belay system:

- Belay line- Shall be rated at a minimum the same strength as the main line

- Belay device- A belay device is essentially a braking device that the belay line is ran through to stop the rescuer in case of uncontrolled descent or mainline failure. There are many belay devices available commercially and site built. Any belay device used must meet the requirements as previously outlined.

- Belayer- The belayer plays a vital role in the overall operation of the rope system. They are responsible for controlling the belay device with the proper technique and keeping slack out of the belay line

- Release Device- A release device allows the tension to be transferred from the belay line back to the mainline when the cause of the failure or descent is corrected. Commercial load release straps are available, but they may not allow for a great deal of extension. A Radium Release Hitch (RRH) is a site built release device that is inexpensive and allows for a greater release distance.

Transverse Rescue 540 Belay Device

Commercial load release strap

Commercial load release strap

Tandem Prusik as a Belay Device

Many tests have proven the effectiveness of the tandem prusik as a belay device. It is very inexpensive to construct, lightweight, and with proper training, easy to setup and operate. The tandem prusik belay (TPB) is a soft rope grab device that will clutch and re-grab the rope at 9-

13kN. It has been shown that the TPB will not de-sheath the host rope and will work on rope

A single prusik is suitable for ratchets and connecting a pulley system to a mainline

that is stiff, fuzzy, wet or dirty. It is important to note that the use of two prusik provides only 1- 3kN of additional performance, however, as a belay device it offers twice the amount of nylon to be melted before failure occurs.

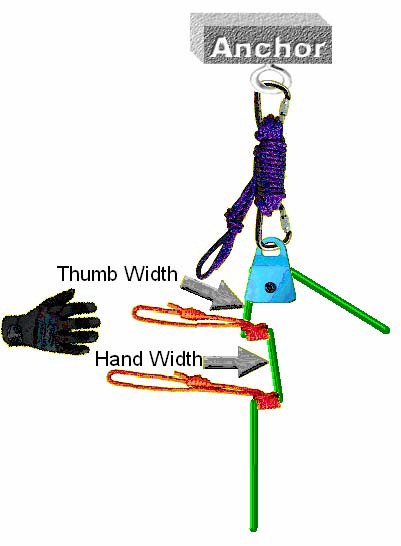

Tandem prusik belays should consist of the following:

- Triple wrap on the host rope

- Shall be ½ the diameter of the host rope at the interior of a “pinch” test

- 3m of 8mm low stretch nylon cord for:

- 1 short prusik 1.35m in length

- 1 long prusik 1.65m in length

Spacing for Tandem Prusik Belay Setup

(Prusiks not attached to anchor carabiner for clarity)

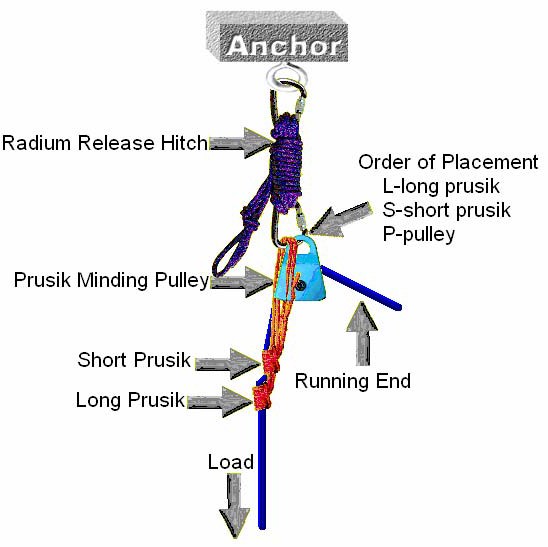

Radium Release Hitch

The Radium Release Hitch (RRH) was developed after comparative analysis and testing of available release devices from 1997 to 1999.

Materials required

- 10m of 8mm nylon low stretch kernmantle cord

- 2 locking carabiners

How to Tie

- Tie a figure 8 on a bight and clip into the load side of the carabiner on its spine

- Clip the standing part of the cord up through the anchor carabiner, back down through the load carabiner; bring it back up to the anchor and tie a Münter Hitch onto that anchor carabiner on its gate side. Ensure that the Münter Hitch is in its release position with the in-feed rope towards the gate side of the carabiner. A reasonable length for the hitch is 4- 6”.

- Secure the RRH using a bight to tie a half hitch around the entire package below the Münter Hitch, and then back it up with an overhand knot on a bight, again around the entire package.

- Tie a figure 8 on a bight at the other end and clip it to a secure anchor

►

Example of a Tandem Prusik Belay System with a Radium Release Hitch

Operating a Tandem Prusik Belay

The method that is used to operate a TPB is known as the “slack in hand technique”. The belayer is pulling slightly on the load to prevent excess slack in the system while holding the two bridges of the prusiks in the other hand, keeping the palms of the hands perpendicular to the ground. The belayer must keep their thumbs over the top of the rope, if the belay system where to activate due to an uncontrolled descent, the line will be forced out of the belayer’s hands, setting the prusik.

S T R E N G T H O F B E L A Y C O M P O N E N T S

Component Drop Test Breaking Strength

- Tandem 8mm Prusik Clutch at 10-14KN

- Single 8mm Prusik Clutch at 9-13KN

- Radium Release Hitch 35KN

- 540° Rescue Belay 70KN

Chapter8

- Define the types of hauling systems

- Understand the “Tension” or “T-method” for calculating theoretical mechanical advantage

Mechanical advantage is created through the application of moving pulleys

Hauling systems are used in situations where it is not possible or practical to lower once a rescuer has secured the patient. Some examples are: cannons, gorges, rivers, caves, mine shafts and other confined spaces.

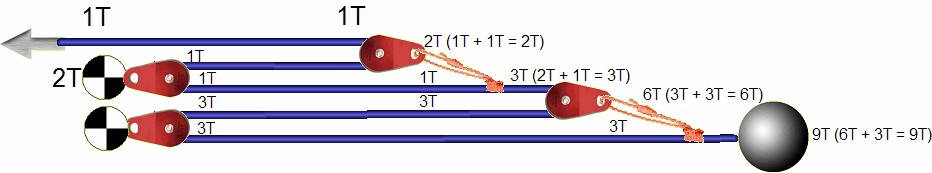

Pulley systems are often used to create mechanical system and make ideal hauling systems. A pulley system’s ideal mechanical advantage (IMA) is expressed as a ratio of the amount of output force to the amount of input force (i.e. 3:1 or “3 to 1”). The input force is the tension that you apply to the system, and is always expressed as one. IMA assumes that there are no losses in the pulley system due to pulley friction, ropes rubbing, bending or unbending.

It is important to

understand

how tension is applied through

a pulley system. Mechanical

advantage is gained by increasing the number of times the initial input of one is applied to the load. This can be accomplished many ways through different pulley system and rigging techniques.

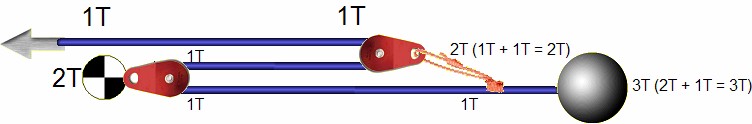

Calculating Ideal Mechanical Advantage

A common method used to calculate the IMA is referred to as the tension method, or T-method. The key to understanding the T-method is in recognizing what happens to the tension in the rope as it flows through the pulley system. Whenever there is a “junction” in the ropes of the pulley system the tension on one side of the rope must be equal to the tension on the other side. This may be where one rope attaches to another rope, or one rope acts on more than one rope. If a rope having a unit of one makes a 180° change of direction through a pulley (junction), then whatever that pulley is connected to receives two units of tension. Essentially, two ropes each having a unit of one (for a total of two units of tension) are acting on, and being opposed by, what the pulley is connected to. Example of tension distribution:

![]()

Steps for T-Method

- Assign one unit of tension to where you pull on the pulley system (input).

- Follow the rope through the pulley system and when you encounter a junction, apply the principles of tension distribution. Keep track of all units of tension through to the load.

- Total all units of tension that reach the load; the IMA is the ratio between this total and the initial one unit of tension (i.e. 3:1, 6:1).

Types of Pulley Systems & Applying T-Method

A simple pulley system is where all ropes are under tension, and all traveling pulleys are moving at the same rate. An example of a simple system would be a 3:1, as shown in the example below:

A compound pulley system is essentially a simple pulley system acting on another simple pulley system. Pulleys may travel at different speeds and in different directions, based on the IMA of each simple pulley system. An example is a compound 9:1 as shown below:

A complex pulley system is defined as a system that is neither simple nor compound. These types of systems may have limited applications in rope rescue scenarios.

Mechanical Advantage Use

As a rule of thumb, never exceed a value of “18” on a mechanical advantage system. This is calculated by multiplying the number of haulers times the amount of TMA. Example:

9 haulers on a 3:1 system = 18

3 haulers on a 6:1 system = 18

Resources

www.coloradotechrescue.com www.pmirope.com www.animatedknots.com www.riggingforrescue.com

http://www.homelandsecurity.az.gov/TS_Comm.htm

References

Animated Knots By Grog. (2007, January 14). Search and Rescue Knots.

//http://www.animatedknots.com/indexrescue.php?LogoImage=LogoGrog.jpg&

Brown, M. G. (2000). Engineering practical rope rescue systems. Albany, NY: Delmar Thomson Learning.

Gibbs, M. (2002, September 24). Rigging for Rescue. Seminar handouts

Larson, A. (1990). Rescue systems testing background and summary. Invemere, B.C., Canada: BCCTR.

Lipke, R. (1999). Technical rescue riggers guide. Bellingham, WA: Conterra.

National Fire Protection Agency (1999). NFPA 1670 standard on operations and training for technical rescue. Quincy, MA: NFPA.

National Fire Protection Agency (2001). NFPA 1983 standard for fire service life safety rope and system components. Quincy, MA: NFPA.

National Fire Protection Agency (2000). NFPA 1006 standard for rescue technician professional qualifications. Quincy, MA: NFPA.

Smith, B., & Padgett, A. (1996). On rope (Rev. ed.). Huntsville, AL: National Speleological

Society.

Vines, T., & Hudson, S. (2004). High angle rescue techniques (3rd ed.). St. Louis, MO: Elsevier Mosby.

Attachments

This page left intentionally blank

Colorado Technical Rescue Rope Rescue

Rappelling Commands and Safety Check

Before the rappeler rigs into the system the belay line must be ready and attended. The rappeler communicates with the belay persons and the belay persons communicate back when ready. Communication is as follows:

(Rappeler to top belay) On Belay

(Top Belay to rappeler)Belay On

Rappeler attaches safety line to harness. (Rappeler to bottom belay) On Belay

(Bottom belay to rappeler) Belay On

Now rappeler rigs into the system.

ABCDE: 5-Point Safety Check– done the rappeler goes over the edge.

Anchor – Rigged correctly; back-tied?

Belay- Rigged correctly; belayer ready (top and/or bottom)?

Carabiners- locked and not side or 3-way loading

Descent control device- (eight plate, brake bar, ID, etc.) Rigged correctly?

Edge- (protection and personnel) in place and ready.

(Rappeler to top and bottom belay) On Rappel

(Belayer to Rappeler) Rappel On

Rappel makes controlled descent to the ground, once on the bottom: (Rappeler to top and bottom belay) Off Rappel

Colorado Tech Rescue Rope Rescue

Command & Communication

Team Positions:

Operations– Overall responsibility of operations. May give commands to raise or lower the load.

Belay– Manages belay line

Mainline– Can be managing a descent control device (brake bar, etc.) or haul team Edge– 1 or more people, tied in, places edge protection, assist load over edge, may provide communication to lower or raise load

Attendant– Manages handling and packaging of the patient, cleans/protects route Haul Team– Rescuers used in mechanical advantage systems. Have only one spokesperson for haul team.

Size Up:

- Identify edge transition. Where is victim located? Are they protected from debris?

- Identify anchors. Man-made, natural or improvised.

- Establish belay position (3m from edge).

- Establish mainline position (10m from edge).

Commands for Lowering:

Operations: Response:

First Stage- Roll Call

Belay ready? Ready! (Belayer ready with no belay slack)

Standby! (If not ready-advise on time)

Mainline ready? Ready! (Device is unlocked & ready to feed)

Edge (1 and/or 2) ready? Ready! (In position to move the load; edge pro)

Attendant ready? Ready! (Properly adjusted, prepared for rescue)

Second Stage- Position the Load

Attendant approach the edge! (Edge people assist, slack the mainline if necessary)

Attendant stop at edge, load the brake! (When at proper location near edge)

Edge ready? Ready! (Edge pro placed, ready to push out)

Attendant ready? Ready! (Hands on litter, ready for pre-tension)

Third Stage- Pre-Tension the System

Mainline, one-bar the rack, advise when ready! (Takes slack out of mainline) Vector the mainline

Fourth Stage- Move the Load

Attendant lean back!

Edge push out!

Main down slow!

Additional Commands

Stop! This can be given by anyone. Why? Slow! Self explanatory

Down, down– Go faster. Stop, stop, all stop– All finished.

British Columbia Council of Technical Rescue Research Section

Box 399, Invemere, B.C. Canada V0A 1K0 August 2, 1990

RESCUE SYSTEMS TESTING

Background and Summary

The B.C. Council of Technical Rescue’s (BCCTR) first tests were done in conjunction with the Provincial Emergency Program’s Third Annual Technical Seminar, March 1982. As more testing took place each succeeding year we had to hold the testing as a separate session outside of the annual week long seminar. These tests were expanded further during test sessions that took place in Denver, Colorado, (Fall 1987) and Sedona, Arizona (Spring 1989).

The BCCTR has the following minimum standard with a

200 kg mass (two persons and equipment) tied to 3 meters of rope the belay system must be able to withstand a 1 meter drop of the load and stop it in less than 15 kilonewtons of force.

It is of great concern that a number of systems in present use cannot manage this bare minimum! To date the only belay system successfully in accordance with the above standard is the Tandem Prusik Belay (TPB). Like other belay techniques it requires competent training and continued practice for safe operation, but it is also relatively easy to learn and does not rely on the strength of the belayer.

The Tandem Prusik is of unequal lengths and is clipped into the same carabineers, generally with a load releasing hitch between the prusiks and the anchor. The prusik are pushed together for ease of handling for most operations. During raises the prusik minding pulley makes their use particularly easy. Two prusik are needed where shock loading is a possibility, such as the belay line, and are also desirable in high load situations such as highlines. They do not share the work equally though and the primary purpose for two is not to increase the tension at which slippage occurs to twice what it was for one prusik (for that it does not hold true), but rather to have twice as much mass of nylon that must be melted before failure occurs. A single 8mm three- wrap prusik of nylon kernmantle low-stretch cord is suitable for ratchets and connecting the pulley system to the mainline.

On rigid towers tandem 8mm three-wrap nylon kernmantle prusiks gripping an 11.1mm low-stretch belay line would consistently hold a 175cm (69 in) fall in Denver and a 200cm (79 in) fall in Sedona (250cm if only tests of nylon prusiks on a nylon belay line are considered). In Denver a Gibbs ascender would totally cut off the rope and the test block would crash to the ground on a 75cm (30 in) fall. At 50cm (20 in) the Gibbs often does serious damage, if not cutting the rope, then tearing the sheath and bunching up the rope or forcing the rope beside the cam. Even a 25cm (10 in) drop the Gibbs often starts to display this condition where the rope is forced around the side of the cam and between the cam and between the cam and the side plate of the U shell. Since the Gibbs was considered, until the recent introduction of the Rescucender, to be the gentlest ascender, one was not surprised to see that other ascenders damaged the rope on similar drops. To date no ascender tested has meet the BCCTR 1 meter minimum.

Most manufactures include (or should) a notice in their material that their ascenders are designed for a single person ascending a line. New slow pull tests applying constant tension have shown that many of them will totally cut off an 11.1 mm nylon kernmantle rope without warning at 1/3 of its rated strength or less. Many safety minded rescue groups will not use ascenders in haul systems or as ratchets.

Failures during tests in the mid 1980’s showed that belay devices such as slot type belay plates and descenders allowed transmission of forces to the belayer that could result in injury. Not desiring to hurt anyone, these tests were discontinued. More recent tests have shown that a rescue load cannot be held even statistically (no

fall involved) by many slot type belay plates. Manufactures of these devices should be encouraged to document the units efficiency (output/input) with representative ropes so the purchaser can see if it is below the .05 efficiency level the BCCTR recommends as a ceiling for belay devices to be used with rescue loads.

When tested in Denver with the LR Hitch between the tandem 8mm prusiks and the anchor the combination once held a 300 cm fall (fall factor of 1). In Sedona this same combination held a 300 cm fall with some materials but not with others. Without an LR Hitch wet prusiks managed a 275 cm fall and wide spaced prusiks 300 cm. One may feel that a larger diameter prusik may be desirable since melting does occur within the prusiks when such severe falls are arrested, however this has not been confirmed. It appears (all else equal) that larger diameter prusiks do not grip quite as well and slip further, which generates more heat. There may be a case for using 9mm prusiks (if suitable material can be found) on 12.7 mm belay lines but further testing is necessary. One must keep in mind that less stretch in a larger diameter rope will mean that more of the energy of the fall must be absorbed by the belay rather than in the rope itself.

I will caution you that texture, stiffness, and sheath thickness etc. of the prusik material can have some effect on its performance. Our supply for 8 mm nylon kernmantle accessory cord is the European manufactures such as Edelrid, Mammut, etc. And this is our present standard. Our tests indicate that other materials such as Wellington-Puritan polyester Prusik Rope has a tendency to grip too well and often fails instead of sliding.

Erratic results suggest that one should also stay away from ropes coated with Rhino-Kote ™ if you intend to use prusiks for belaying. All our information indicates that prusiks of suitable materials perform better as a belay than mechanical rope clamps even when wet or muddy.

Prusiks tighten in to the diameter of the rope (within reason) and grip all around its surface. When slippage occurs they generate an operating temperature that is suitable to the materials and energy absorption needs we are dealing with. The water seems to be driven off by the heat. This added energy outlet, for wet prusiks, may actually make the prusik stand up better. The behavior of prusiks on “icy” ropes has yet to be determined, however tests results confirming that falling rescues loads can be successfully arrested by the use of mechanical rope clamps, descenders or slot type belay plates used on “icy” ropes are not available either.

While it is true that different materials give different results, this must not be blown out of proportion. Assuming that the material is not too stiff to work well as a haul or ratchet prusik, is sufficiently large (8 mm), and two 3-wrap prusiks are used in tandem, then it can be said that you have a better chance of catching a severe fall with prusiks (regardless of whether they are nylon, perion, polyester, braid on braid, plaited, kernmantle, 3 strand twisted) than with mechanical rope clamps or slot type belay plates. And when using nylon kernmantle low-stretch prusiks on a nylon kernmantle low-stretch belay line the improvement is significant.

Note: This sheet is a brief summary and does not give the details necessary to operate a Tandem Prusik Belay safely

Material Strengths Card

| MATERIAL | STRENGTH |

| 6mm Cord | 7.5 KN |

| 7mm Cord | 10 KN |

| 8mm Cord | 13-15 KN |

| 11mm Cord | 30 KN |

| 13mm Cord | 40 KN |

| Aluminum Carabiner | 22-30 KN |

| Steel Carabiner | 40 KN |

| Large Diameter Pulley | 32 KN |

| PMP | 36 KN |

| Brake Rack | 46-56 KN (breaks rope @ 26 KN) |

| 25mm Tubular Webbing | 18 KN |

| 25mm Flat Webbing | 26 KN |

| W2P1 (Tub/Flat) | 24-26 KN/32 KN |

| W3P2 (Tub/Flat) | 35-40 KN/46 KN |

| Radium Release (RRH) | 35+ KN |

| 540 Rescue Belay | 70 KN (NFPA -36 KN) |

| Tandem Prusik | Clutch at 10-14 KN |

| Single Prusik | Clutch at 9-13 KN |

Figure eight “follow through”

Figure eight “follow through” Water bend for webbing

Water bend for webbing Emergency apparatus – An axle or tire may be used on a vehicle for an anchor. Lock out/tag out procedures should be followed to prevent the vehicle from being moved while in use as an anchor

Emergency apparatus – An axle or tire may be used on a vehicle for an anchor. Lock out/tag out procedures should be followed to prevent the vehicle from being moved while in use as an anchor Bolts and hanger system – This is a specialized system used to install an anchor point in a wall or rock face. A hole is first drilled into the material and an expansion anchor or a bolt set in epoxy is placed. Then a hanger is attached and secured to the bolt. Bolts and hangers are generally designed

Bolts and hanger system – This is a specialized system used to install an anchor point in a wall or rock face. A hole is first drilled into the material and an expansion anchor or a bolt set in epoxy is placed. Then a hanger is attached and secured to the bolt. Bolts and hangers are generally designed © COMPLIT!D PICICIT HOL01AST

© COMPLIT!D PICICIT HOL01AST

Responses