Exploring the Landscape of Non-Destructive Testing: A Comprehensive Guide to NDT Methods

Non-Destructive Testing (NDT) plays a pivotal role in ensuring the safety and integrity of materials and structures across various industries. From aerospace to construction, NDT methods provide invaluable insights without causing damage to the subject. In this comprehensive guide, we delve into 20 prominent NDT methods, shedding light on what they are, their applications, advantages, and disadvantages. Whether you’re an NDT professional or simply curious about this fascinating field, this guide offers a detailed overview of the techniques that shape modern inspection and quality control.

1. Ultrasonic Testing (UT)

- What It Is: Utilizes high-frequency sound waves to detect flaws or measure material thickness.

- Uses: Inspection of welds, castings, forgings, and composite materials.

- Advantages: High sensitivity, ability to detect deep flaws, provides detailed information.

- Disadvantages: Requires skilled operators, surface must be accessible, limited use on thin materials.

2. Radiographic Testing (RT)

- What It Is: Employs X-rays or gamma rays to view the internal structure of a component.

- Uses: Inspection of welds, castings, and complex geometries.

- Advantages: Provides permanent record, applicable to various materials.

- Disadvantages: Safety concerns with radiation, expensive, time-consuming.

3. Magnetic Particle Testing (MT)

- What It Is: Reveals surface and near-surface discontinuities in ferromagnetic materials.

- Uses: Inspection of automotive parts, pipelines, and structural steel.

- Advantages: Quick, sensitive to surface flaws, relatively inexpensive.

- Disadvantages: Only applicable to ferromagnetic materials, surface preparation required.

4. Liquid Penetrant Testing (PT)

- What It Is: Detects surface-breaking defects using a liquid with high surface wetting characteristics.

- Uses: Inspection of non-porous materials like metals, plastics, and ceramics.

- Advantages: Simple, low cost, highly sensitive to small surface discontinuities.

- Disadvantages: Only detects surface flaws, requires thorough cleaning.

5. Eddy Current Testing (ET)

- What It Is: Employs electromagnetic induction to detect flaws in conductive materials.

- Uses: Inspection of tubes, aircraft structures, and coating thickness measurement.

- Advantages: Sensitive to small cracks, no need for direct contact, immediate results.

- Disadvantages: Limited to conductive materials, complex interpretation.

6. Visual Inspection (VI)

- What It Is: Visual observation of a test object.

- Uses: General inspection for maintenance, quality control, and conformity assessment.

- Advantages: Simple, quick, often the first line of inspection.

- Disadvantages: Surface-only inspection, limited to accessible areas.

7. Acoustic Emission Testing (AE)

- What It Is: Monitors transient elastic waves to detect crack growth.

- Uses: Monitoring of pressure vessels, bridges, and structural health.

- Advantages: Real-time monitoring, can detect active flaws.

- Disadvantages: Requires specialized equipment, sensitive to background noise.

8. Leak Testing (LT)

- What It Is: Verifies the integrity of a component or system against leaks.

- Uses: Testing of seals, pipes, tanks, and pressure vessels.

- Advantages: Detects leaks and their locations, ensures safety.

- Disadvantages: Can be time-consuming, method-dependent sensitivity.

9. Infrared and Thermal Testing (IRT)

- What It Is: Utilizes infrared cameras to detect changes in thermal properties.

- Uses: Inspection of electrical systems, building envelopes, and heat loss detection.

- Advantages: Non-contact, provides visual mapping, real-time analysis.

- Disadvantages: Sensitive to environmental conditions, interpretation can be complex.

10. Ground Penetrating Radar (GPR)

- What It Is: Employs radar pulses to image the subsurface.

- Uses: Detection of underground utilities, archaeological investigations.

- Advantages: Non-invasive, provides depth information, versatile.

- Disadvantages: Requires skilled interpretation, limited penetration in certain soils.

11. Laser Testing Methods (LM)

- What It Is: Includes techniques like laser profilometry and shearography for surface inspection.

- Uses: Inspection of composite materials, surface topography analysis.

- Advantages: High precision, non-contact, adaptable to various materials.

- Disadvantages: Expensive equipment, sensitive to environmental conditions.

12. Magnetic Flux Leakage (MFL)

- What It Is: Utilizes magnetic fields to detect corrosion and pitting in ferrous materials.

- Uses: Inspection of pipelines, tanks, and wire ropes.

- Advantages: Sensitive to material loss, applicable to coated surfaces.

- Disadvantages: Only applicable to ferromagnetic materials, complex interpretation.

13. Neutron Radiographic Testing (NR)

- What It Is: Employs neutron radiation to inspect materials.

- Uses: Inspection of aerospace components, detection of hydrogen in metals.

- Advantages: Penetrates materials that X-rays cannot, provides unique information.

- Disadvantages: Requires specialized facilities, safety concerns with radiation.

14. Vibration Analysis (VA)

- What It Is: Analyzes vibrations in mechanical systems to detect imbalances and faults.

- Uses: Monitoring of rotating machinery, predictive maintenance.

- Advantages: Early fault detection, condition monitoring.

- Disadvantages: Requires specialized equipment and expertise, limited to vibrating systems.

15. Time of Flight Diffraction (TOFD)

- What It Is: A specialized ultrasonic technique used for weld inspection.

- Uses: Inspection of welds in pipelines, pressure vessels, and structural components.

- Advantages: Highly accurate sizing of defects, provides full imaging.

- Disadvantages: Requires skilled operators, limited to certain geometries.

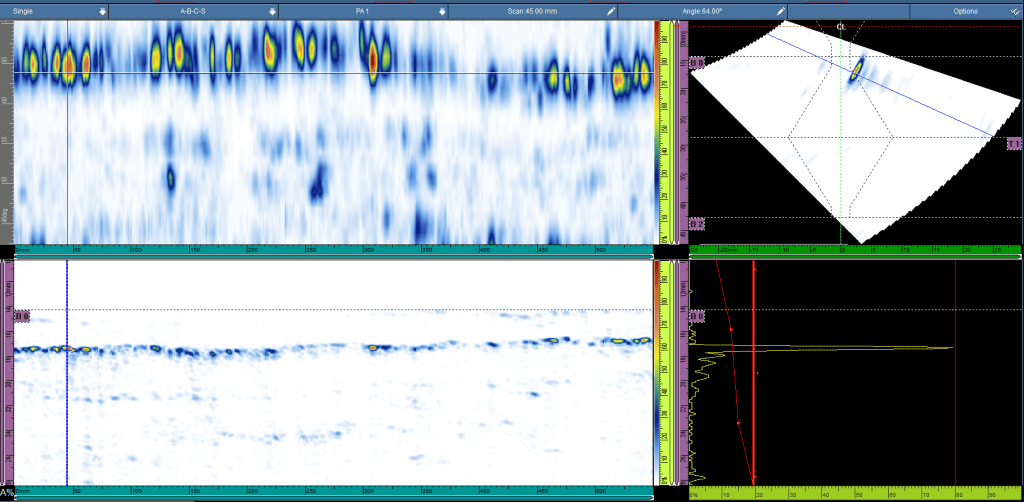

16. Phased Array Ultrasonic Testing (PAUT)

- What It Is: An advanced ultrasonic technique with beam steering and scanning patterns.

- Uses: Inspection of complex geometries, welds, and corrosion mapping.

- Advantages: Versatile, provides detailed imaging, adaptable to various applications.

- Disadvantages: Expensive equipment, requires specialized training.

17. Guided Wave Ultrasonic Testing (GWUT)

- What It Is: Utilizes guided ultrasonic waves to inspect large structures.

- Uses: Inspection of pipelines, rails, and long-range structures.

- Advantages: Long-range inspection, applicable to buried or coated structures.

- Disadvantages: Complex interpretation, sensitivity to geometric changes.

18. Bubble Leak Testing (BLT)

- What It Is: A subtype of leak testing where bubbles are observed to detect leaks.

- Uses: Testing of seals, valves, and containers.

- Advantages: Simple, direct visualization of leaks.

- Disadvantages: Qualitative, limited to accessible surfaces.

19. Tap Testing

- What It Is: Tapping is used to detect delamination or debonding in materials.

- Uses: Inspection of composite materials, bond integrity testing.

- Advantages: Simple, quick, low cost.

- Disadvantages: Subjective, limited to surface-connected flaws.

20. Holographic Testing

- What It Is: Employs optical holography to detect changes in the surface of the object.

- Uses: Inspection of aerospace components, detection of micro-defects.

- Advantages: High sensitivity, full-field inspection.

- Disadvantages: Requires stable environment, complex setup.

The world of Non-Destructive Testing (NDT) is vast and multifaceted, offering a plethora of methods tailored to various applications and industries. Understanding these methods is essential for professionals seeking to ensure the quality, safety, and longevity of materials and structures. As technology advances, so do the possibilities within NDT, opening new horizons for innovation and excellence.

At NDT Inspect, we believe in fostering a community of like-minded professionals who share a passion for NDT. Whether you’re looking to engage with peers, share knowledge, or explore new opportunities, our platform is designed to connect you with the global NDT community.

Join our groups today and become part of a network that thrives on collaboration, learning, and growth.

But that’s not all! By registering on NDT Inspect for free, you can unlock even more features and benefits tailored to your needs. Explore our various membership levels:

- Premium Member: $14.95 initially, then $5.95 per Month.

- Free Memberships: Aerospace Engineer, Health and Safety Expert, Inspector, Inspection Engineer, Mechanical Engineer, NDT Professional, NDT Level III, NDT Engineer, Publisher (Site Contributor), QA QC Professional, Rope Access, Standard Member, Student Member, Welding Inspector, Welding Professional, Company Representative.

- Recruitment Agency: $25.00 initially, then $399.00 per Year.

- Premium Company Member: $199.00 initially, then $990.00 per Year.

These options cater to various industry professionals, students, and companies, providing access to exclusive content, job postings, forums, equipment ads, company databases, and much more. Registration is completely free, and it’s your gateway to a wealth of resources and connections in the NDT world.

Your journey into the dynamic world of Non-Destructive Testing starts here. Join us, and let’s explore the future of NDT together.

Responses