NON- DESTRUCTIVE TESTING OF CONCRETE

INTRODUCTION

The word “concrete” comes from the Latin word “Concretus” (meaning, compact or condensed). Concretes in different forms have been using since beginning of civilization of human being. Today’s modernization is only possible due to the versatile nature of concrete where almost all kinds of structures are possible.

Modern concrete was only possible after invention of method of production of Portland cement. Immediately before invention of Portland cement, hydraulic lime was used for making concrete with pebble and powdered brick as aggregate. The method of producing Portland cement was officially patented by Joseph Aspdin in 1824 and reinforced concrete was invented in 1849 by Joseph Monier. In 1889, the first reinforced concrete bridge was built and first large concrete dams were built in 1936, Hoover Dam and Grand Coulee Dam.

Concrete is composite material bonded together with aggregates (course and fine) and fluid cement which hardens over times. Most concrete used are lime based concrete such as Portland cement concrete or concrete based with other hydraulic cement such as ciment fondu (calcium aluminate cement). Asphalt concrete which is used in road surface is also a type of concrete where cement material is bitumen, and polymer concrete is used sometimes where cement material is polymer.

Quality control in concrete is very important task in construction. Quality has to be controlled during construction and after construction for insuring the requirement of that particular purpose. Quality control can be achieved by conducting several types of test during construction and after construction. After setting of the concrete, basically there are two types of testing; destructive and non- destructive testing.

Non-destructive tests (NDT) are very useful in hydropower structure for evaluating their qualities after concreting. NDT for accessing tunnel lining concrete is usually done after completion of grouting to determine the quality of concrete and grouting.

Besides the tunnel linings, NDT tests are conducted for other concrete structure such as dam, powerhouse and bridge for their qualities after concreting. This paper intends to explain about the types and methods of non destructive tests and its application in concrete used for different structures.

NON DESTRUCTIVE TESTING

Non destructive test is useful especially for existing structures for rehabilitation planning. After destructive earthquake of Baishak 12, 2072, Non destructive testing have been used for accessing the residual strength and determination of concrete defects of buildings of residential uses, apartments, commercial buildings and schools to determine whether they are safe to use further and if damage was repairable, suitable repair plan. it is also useful as an alternative test if destructive test result become doubtful about the concrete quality.

METHODS OF NON DESTRUCTIVE TESTING

Several non destructive methods of testing have been developed to analyze the property of hardened concrete. Followings are the method of testing available in concreting industry.

- VISUAL INSPECTION

Visual inspection is most easy and important non destructive test. It is an initial assessment of which can be done immediately. It can provide the most important information of most trained eye of the Engineer. Visual inspection can detect cracks, spalling, disintegration, color change, weathering, surface blemishes, and lack of uniformity.

It also gives a preliminary indication of the condition of the surface and allows the formulation of a subsequent testing program. Several tools which can be used for visual inspection may be but not limited to; measuring tape, markers, thermometer, anemometer, binocular, borescope, endoscope, magnifying glass, camera, geological hammer.

- HALF CELL ELECTRICAL POTENTIAL TESTING METHOD

This technique is mostly used for assessment of reinforced concrete members where reinforcement corrosion is suspected. Its uses are usually in bridge abutments ad piers, and marine structures. It is simple method of testing and equipments used are very simple.

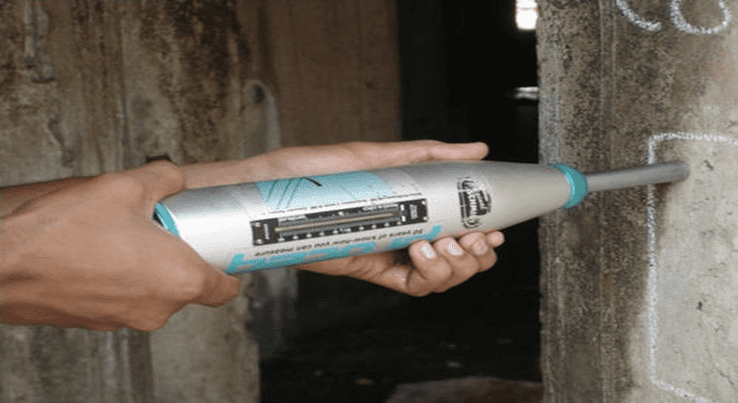

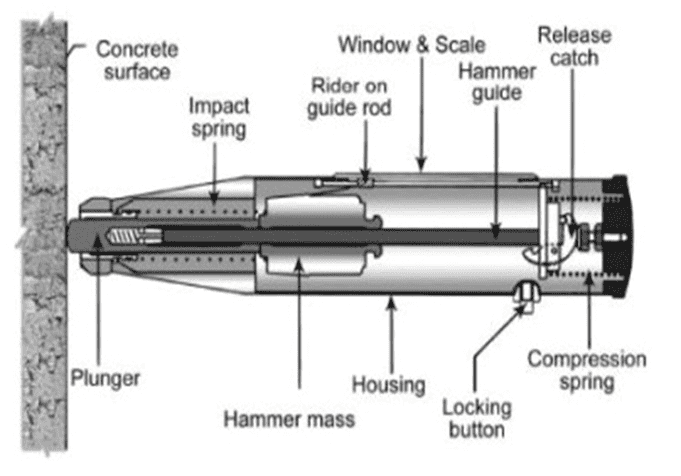

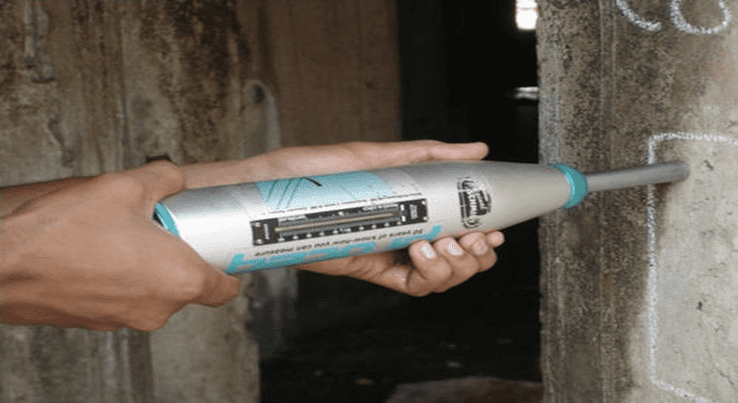

- REBOUND HAMMER TEST

Rebound hammer test is most common Non Destructive Method (NDT) of testing which was developed in 1948 by Swiss Engineer Ernst Schmidt. Rebound hammer test measures the elastic rebound of concrete and the test is useful for estimation of concrete strength and comparative investigation.

As no theoretical assessments have been developed for assessment of concrete, empirical relationship between the rebound hardness and strength are used. There are several factors which may affect the result of rebound hammer tests such as type of aggregate, degree of compaction, age of concrete, dryness/wetness of surface, rigidity of the members to be tested, surface finish of concrete; moulded/traweled, maintenance of rebound hammer, inclination of rebound hammer, type of cement, carbonation and cover. Typical section of rebound hammer and testing method are shown in fig 2.1 and 2.2.

- CARBONATION DEPTH MEASUREMENT TEST

Carbonation is a process of formation of calcium carbonate from hydrated cement material in presence of carbon dioxide and moisture. It is also called depassivation. Carbonation depth measurement test is also simple method of testing. It is usually done to determine the depth of carbonation in concrete and provide the information about risk of reinforcement bar corrosion. To test the carbonation, 1% phenolphthalein is sprayed over suspected surface and if surface remains uncolored then there will be chance of carbonation effect. The depth of carbonation can be found out by using simple formula.

- PERMEABILITY TEST

Permeability of concrete is important when dealing with durability of concrete of water retaining structures and water tight structures. Permeability test measure the how ease the liquid or gases can penetrate into the concrete. There are two widely used method of testing the permeability, first one is initial surface absorption test and second one is modified figg air permeability test. The method mentioned donot measure the permeability directly but develop the permeability index which closely related to method of measurement.

- DYNAMIC OR VIBRATION TESTS

The ultrasonic pulse velocity method was developed in 1940s. The principle of test is based on the progression of ultrasonic wave in elastic medium in which velocity of propagation of ultrasonic wave is measured and velocity is related to the density of medium (v=(e/p)1/2. Strength is deduced from the density of medium and frequency of wave used is 15-150 khz.

These tests include the resonance frequency and mechanical sonic and ultrasonic pulse velocity methods. These tests are use to evaluate the durability and uniformity of concrete, and to estimate of strength and elastic property of concrete.

It can also develop the ultrasonic tomography of the concrete members and detect the different types of defects such as thickness of layer of inferior quality concrete, change in property of concrete, compressive strength and modulus of elasticity.

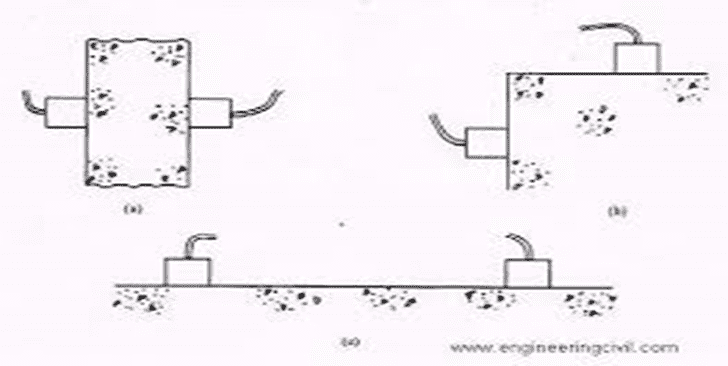

There are three types of testing in pulse velocity method; direct transmission, semi direct transmission and surface transmission as illustrated in Fig. 3.1. Out of three method of testing, direct transmission method is the best but need access to two opposite sides of concrete members. Surface transmission method is shown in photo 1.

There are several factors which affect the result of testing such as degree of coupling, presence of reinforcing bars, concrete temperature, moisture content, mix proportion, age of concrete, stress level in concrete. The correction factors are to be applied for output if above influencing factors are to be encountered while testing.

ULTRASONIC PULSE ECO

Ultrasonic pulse eco method is an acoustic method based on introducing the ultrasonic stress wave into concrete with a piezoelectric element. Signal generation and detection both are done with piezoelectric crystals. Internal feather of concrete can be detected with one sided access to the structures. The principal is based on the measurement of time interval between transmitting the ultrasonic impulse into the structures and receiving an eco.

3.6.2 IMPACT-ECO/RESONANCE FREQUENCY/STRESS WAVE TEST

A number of non destructive test methods rely on the effect a structure has on the propagation of stress wave. The most common techniques are pulse-eco, impact-eco, impulse-response and spectral analysis of surface wave. This method is an effective method of locating the large voids or delaminations in plate like structures e.g. pavements or bridge decks.

The pulse velocity method is widely used method of NDT. The testing procedure is simple and equipment is readily available. However, the relation between strength and pulse velocity is in general not reliable enough for practical purpose.

For overcoming these effects, relative amplitude method may be an alternative method for checking it. For some special types of investigation, it is more convenient to use both the ultrasonic pulse velocity test and the rebound hammer test in association with the concrete compressive strength to establish the concrete quality.

- COMBINED METHODS

The combined method involves the use of ultrasonic pulse velocity and rebound hammer for estimation of strength and durability. It is also called SONREB (SONIC+REBOUND) method which is used to improve the accuracy of estimation of compressive strength of concrete. The compressive strength can be found out by using following formula.

Fck= a x Vb x Sc, where fck= compressive strength, a, b and c are constant, V is the ultrasonic velocity and S is the rebound value.

- PENETRATION AND PULLOUT TECHNIQUE

These tests include use of simbi hammer, spit pins, the Windsor probe and pullout tests. These measure the penetration and pullout resistance of concrete and are used for strength estimation, and they can also be used for comparative study.

- SURFACE HARDNESS TEST

This test includes impact hammer and William testing pistol, which are usually applied for estimation of concrete strength.

- RADIOACTIVE AND NUCLEAR METHODS

These include the x-ray and Gamma ray penetration tests for measurement of thickness and density of concrete. Neutron scattering and Neutron activation methods are used for moisture and cement content determination.

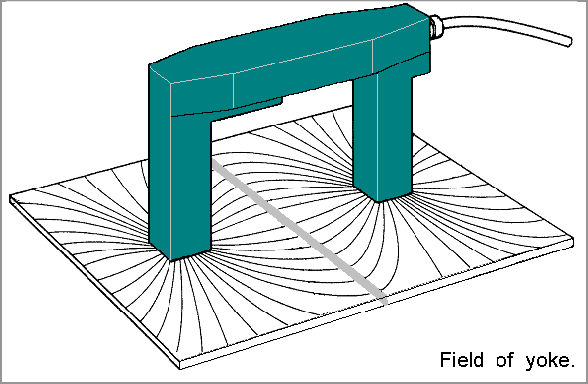

- MAGNETIC AND ELECTRICAL METHODS

Magnetic methods are primarily concerned with the determination of cover of reinforcement in concrete. Whereas, electrical methods, including microwave absorption technique, are used to measure moisture content and thickness of concrete.

- ACOUSTIC EMISSION TECHNIQUE

These are used to study the initiation and growth of cracks in concrete.

- GROUND PENETRATION RADAR

Ground Penetration Radar (GPR) is electromagnetic analogue of sonic and ultrasonic pulse eco method. It is based on the propagation of electromagnetic energy through materials of different dielectric constant. GPR is non destructive technique with wide range of application in testing of concrete. It is useful technique for finding out delamination and other types of defects which can occur in bar or overlaid reinforcement slab or deck. It can also be used for determining the voids and thickness of concrete members.

CONCLUSION

Non destructive Testing is essential tool of concrete quality control after it hardens. For Engineers and Stakeholders, long service life of infrastructures is an ultimate target in this world. Once the concrete hardens, its quality will be assessed only by NDT without breaking it.

Aging and disastrous damage due to natural events like earthquake in concrete structures have updated the urgent need of continuing repair/maintenance of structures. NDT technique and evaluation are gaining importance to plan rehabilitation/repair of the damaged structures.

As concrete is most complex material, NDT result only cannot provide the exact result and it should be evaluated along with the results from standard compression tests. To be a proper data analyst, in depth knowledge and experience are the most important factors for Engineer.

References:

- Indian Standard (IS) 13311 (part 2): 1992- Rebound Hammer

- Indian Standard (IS) 13311 (part 1): 1992- Ultrasonic Pulse Velocity

- BS 1881, Testing Concrete Pt 203

- ASTM C597

- Guide to Non Destructive Testing of Concrete, US Department of Transportation

- Guide Book on Non Destructive Testing of Concrete Structures, IAEA, VIENNA, 2002