Navigating the Complexities of PAUT Corrosion Mapping on Materials Coated with Lead-Based Paint

Corrosion mapping is an essential practice for ensuring the structural integrity of industrial assets like pipelines and tanks. While traditional methods often necessitate the removal of surface coatings, the challenge intensifies when the coating in question is lead-based paint—a hazardous material. This article delves into the innovative use of Phased Array Ultrasonic Testing (PAUT) for corrosion mapping on such materials, both with and without paint removal.

The Dilemma: Lead-Based Paint Coatings

Lead-based paint is not just any coating; it’s a high-risk material associated with severe health hazards, including lead poisoning. Its removal is a complex, regulation-bound process that poses both safety and environmental challenges. Therefore, the prospect of conducting corrosion mapping without disturbing this paint layer is both appealing and complicated.

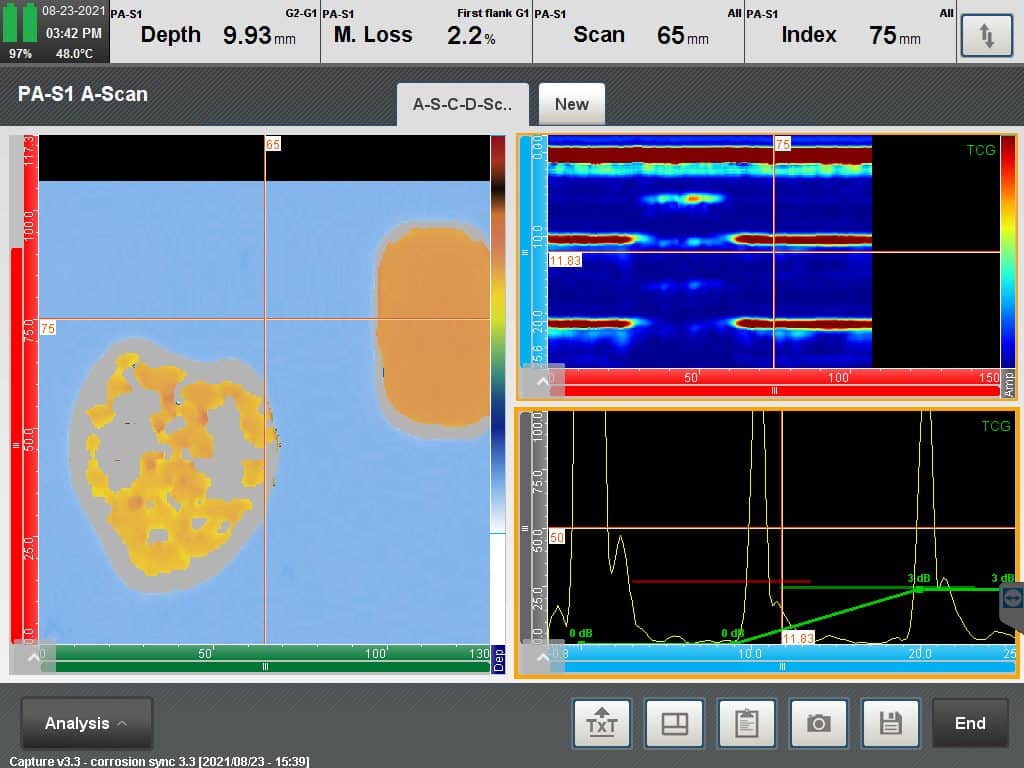

The Power of PAUT

Phased Array Ultrasonic Testing (PAUT) is a cutting-edge non-destructive testing (NDT) technique. It employs multiple ultrasonic elements to direct, focus, and scan beams using a single probe. The advantages of PAUT include:

- Detailed, high-resolution imaging

- Capability to inspect intricate geometries

- Enhanced defect detection and sizing

Safety Protocols

Before initiating any PAUT procedure, safety is paramount:

- Personal Protective Equipment (PPE): Ensure all operators wear the required PPE, including gloves, masks, and eye protection.

- Regulatory Adherence: Comply with all local and national guidelines for handling lead-based materials.

Equipment Configuration

Calibration

Calibrate the PAUT device using a calibration block that mimics the material and geometry of the asset under inspection.

Probe Selection

Select a probe with an appropriate frequency and element size, considering the material and its thickness. Lower frequency probes may be more effective for penetrating the paint layer.

Couplant Utilization

A high-viscosity couplant can enhance the transmission of ultrasonic waves through the paint.

Testing Approaches

Traditional Testing with Paint Removal

The conventional approach involves stripping the lead-based paint from the area to be tested, followed by standard PAUT procedures for data collection and analysis.

Testing Without Paint Removal

Initial Scanning

Conduct a preliminary scan to gauge the signal quality through the paint. Modify settings like gain and focal depth to optimize for the paint layer.

Data Collection and Interpretation

Collect data while ensuring good probe contact with the surface. The presence of lead-based paint may introduce noise, requiring specialized interpretation skills.

Post-Examination Steps

- Documentation: Compile a thorough report detailing the findings.

- Safety Measures: Dispose of contaminated materials and used PPE according to regulations.

Limitations and Considerations

- Testing accuracy may be compromised by the paint layer.

- Additional validation methods may be necessary to confirm results.

- The complexity of interpreting data increases when testing through paint.

Conclusion

PAUT stands as a promising solution for corrosion mapping on assets coated with lead-based paint. While the method comes with its set of challenges, especially when opting not to remove the paint, it offers a potentially safer and more efficient alternative to traditional techniques. As technology evolves, PAUT is poised to become an increasingly reliable tool for this specialized application.

Responses