Acoustic Emission (AE)

Public NDT

Active 4 months ago

Welcome to [NDT Inspection Portal]’s acoustic emission (AE) group, a place for professionals to... View more

Public NDT

Group Description

Welcome to [NDT Inspection Portal]’s acoustic emission (AE) group, a place for professionals to connect and discuss the latest techniques and technologies in AE.

Acoustic emission (AE) is a specialized field within non-destructive testing (NDT) and inspection that involves the detection and analysis of acoustic waves or vibrations emitted from materials or structures as a result of internal or external stimuli. It is an important aspect of ensuring the safety and reliability of components, structures, and materials in various industries, including manufacturing, construction, and engineering.

Acoustic emission (AE) involves the use of specialized sensors and equipment, such as piezoelectric transducers, to detect and analyze acoustic waves or vibrations emitted from materials or structures. It may involve the use of other NDT methods, such as ultrasonic testing and radiographic testing, to identify any potential issues or defects, such as cracks, porosity, or corrosion. AE is often used to monitor the integrity and performance of components, structures, and materials in real-time and to predict potential failures or issues. It is particularly useful in situations where it is not possible or safe to physically access the inspection site or to apply load or stress to the material or structure.

Our member group offers a platform for sharing knowledge and best practices on AE and its applications in various industries. Join our community of experts from around the world and be a part of the conversation on advancing the practice of AE and its applications in the field of NDT and inspection. Whether you are new to AE or an experienced professional, you’ll find valuable resources and a welcoming community in our group.

How does acoustic emission testing work?

How does acoustic emission testing work?

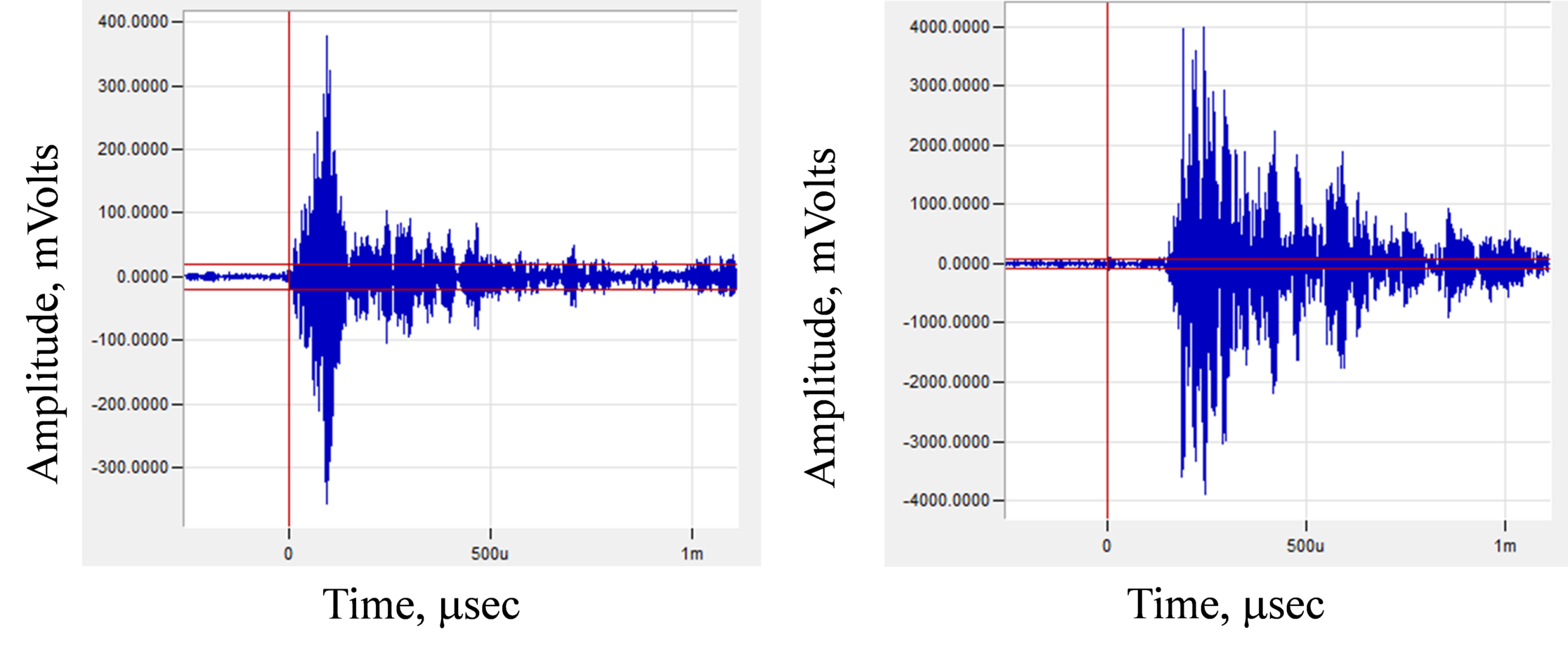

Posted by arsal on 12/10/2021 at 9:28 amAcoustic emission testing works by mounting small sensors onto a component under test. The sensors convert the stress waves into electrical signals, which are relayed to an acquisition PC for processing.

Unknown Member replied 2 years, 6 months ago 2 Members · 1 Reply- 1 Reply

Unknown Member

Member18/08/2023 at 1:27 pmA complete guide to Acoustic emission testing for your consideration.

Acoustic emission testing (AET) is a non-destructive testing (NDT) technique that detects flaws in objects by monitoring the pattern of ultrasonic stress waves within structures and materials through an attached set of AE sensors. These AE sensors will convert the stress waves into electrical signals and relay those signals to an external equipment/device for processing.

Acoustic emission testing, or acoustic emission monitoring, uses sound waves to detect and locate defects in structures and materials. It is often used in the manufacturing and construction industries to detect cracks, flaws, corrosion, and other defects.

Acoustic emission testing is also called Acoustic Emission (AE), Acoustic Testing (AT), Acoustic NDT, or AE Testing.

Acoustic emission testing is one of the most common and useful methods of non-destructive testing (i.e., testing that allows inspectors to collect data on materials without harming them).

The primary advantages of acoustic emission testing are that it allows inspectors to test a material’s entire load history without damaging it.

Historically, AE has been used only for inspecting and maintaining expensive structures due to the high costs associated with it. But new developments have helped lower the cost of AE equipment, and it is becoming more accessible for a host of inspection applications.

Log in to reply.