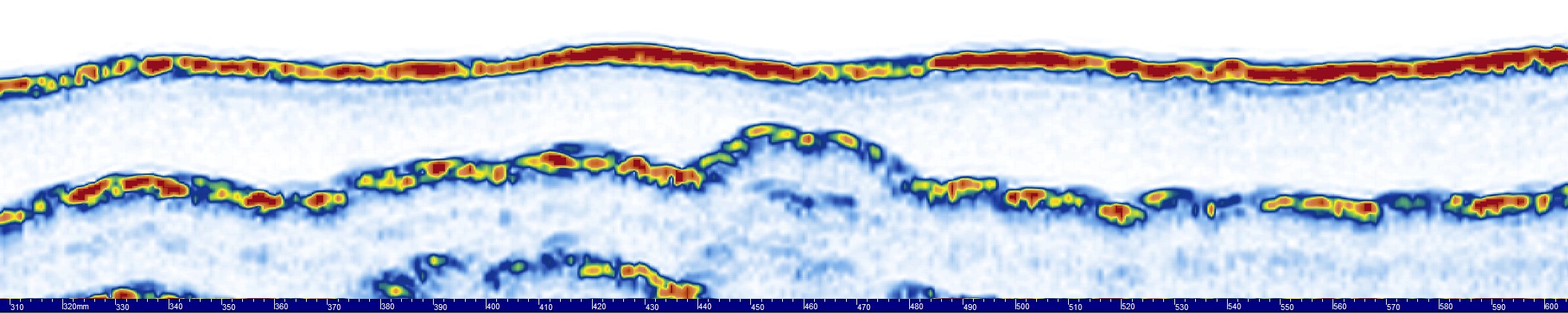

Corrosion Mapping (CM)

Welcome to [NDT Inspection Portal]’s corrosion mapping group, a place for NDT professionals to connect... View more

Setup Parameters for HydroFORM probe (Corrosion Mapping)

Setup Parameters for HydroFORM probe (Corrosion Mapping)

Setup Parameters & Written Instruction for HydroFORM probe (WT in excess of 25mm).

Probe: Auto-Detect or 7.5L64-I4

Wedge: Custom Definition for thick gasket plate:

Angle: 0º Orientation: Normal Height: 31mm Velocity: 1480.00m/s Primary Offset: -30.5mm Secondary Offset: 0.00mm

(saved in ‘User’ defined wedges as HydroFORM thk mtl)

Law: Linear at 0º with Overlap / 4 Element Aperture / First Element: 1 /

Last Element: 64 / 4mm focus depth

Pulser: Low Energy / Optimum PRF

Reciever: Bandpass Filter 7.7 MHz / Video Filter: ON / Points Qty: 640

Setup:

1) Attach Gasket Plate to Probe Housing. Place Probe assembly on V1 block and flood column with water. Agitate probe to free water column from bubbles and to ensure steady couplant flow.

2) Set display to A-S-[C] (C-Scan left ‘OFF’).

3) Set Range Start to -5mm to show first interface echo.

4) Reduce Gain until Interface Echo approx. 100% FSH.

5) Set Range to see 2 backwall echoes.

6) Set Gate ‘I’: Start: -5mm / Width: To cover Interface Echo / Mode: ‘I/’

7) Set Gate ‘A’: Start: Adjacent to Interface Echo / Width: To cover 1st BWE / Mode: Synchro ‘/’

8) Set Gate ‘A’: Start: Adjacent to Gate A End / Width: To cover 2nd BWE / Mode: Synchro ‘/’

9) Select ‘Thickness’ tab in Gates/Alarms menu; Source: ‘A/ – I/’, set ‘Min’ to Gate A Start value, set Max to 2 x Nominal Wall thickness (this can be changed at analysis stage, but causes problems if set too low prior to inspection).

10) Select ‘Display’ menu. Activate C-Scan.

11) Select ‘View Settings’ submenu, set Source 1 to ‘Thickness’; Source 2 to ‘A%’

12) Select ‘Properties’ submenu. Select Colour Palette. Check ‘Thickness’ values are the same as entered in Step 9.

13) Select ‘Sizing’ Menu; ‘Curve Setup’. Build Manual TCG as follows:

Point 1: Position after interface, no TCG gain

Point 2: Position at 1st BWE, add TCG gain to bring 1st BWE to 100% FSH

Point 3: Position at 2nd BWE, add TCG gain to bring 2nd BWE to 100% FSH

Point n: Repeat above steps for subsequent points until TCG covers inspection

range.

14) Select ‘Scan’ > ‘Inspection’. Select ‘Encoder 1’. Calibrate encoder as normal procedure. Reference encoder resolution is 8 counts/mm, site cal gives 7.77 counts/mm.

15) Select ‘File’ > ‘Data Settings’. Confirm ‘Data Selection’ is for ‘All A&C Scans’, and define scan file save name. Note – adding a hastag ‘#’ in place of a numeral in the file name will cause the Omniscan to save subsequent files with consecutively-numbered file names for each punch of the ’SAVE’ button, reducing time between scans if so desired.

Sorry, there were no replies found.

Log in to reply.