Dye Penetrant Inspection (PT) (DPI)

Welcome to [NDT Inspection Portal]’s dye penetrant testing group, a place for professionals to connect... View more

Simple PT process

Simple PT process

The process of performing a dye penetrant inspection, also known as liquid penetrant testing, typically involves the following steps:

Surface preparation: The surface of the test object must be clean and free of contaminants, such as dirt, oil, and grease, in order for the penetrant to be effective. The surface is usually cleaned using a solvent or detergent and then dried.

Application of penetrant: The penetrant is applied to the surface of the test object using a brush, spray, or dip method. The penetrant is allowed to penetrate into any surface defects, such as cracks or pores, for a specified time period.

Removal of excess penetrant: Any excess penetrant is removed from the surface of the test object using a cleaner or solvent. This step is important to ensure that the penetrant remaining in the defects is clearly visible.

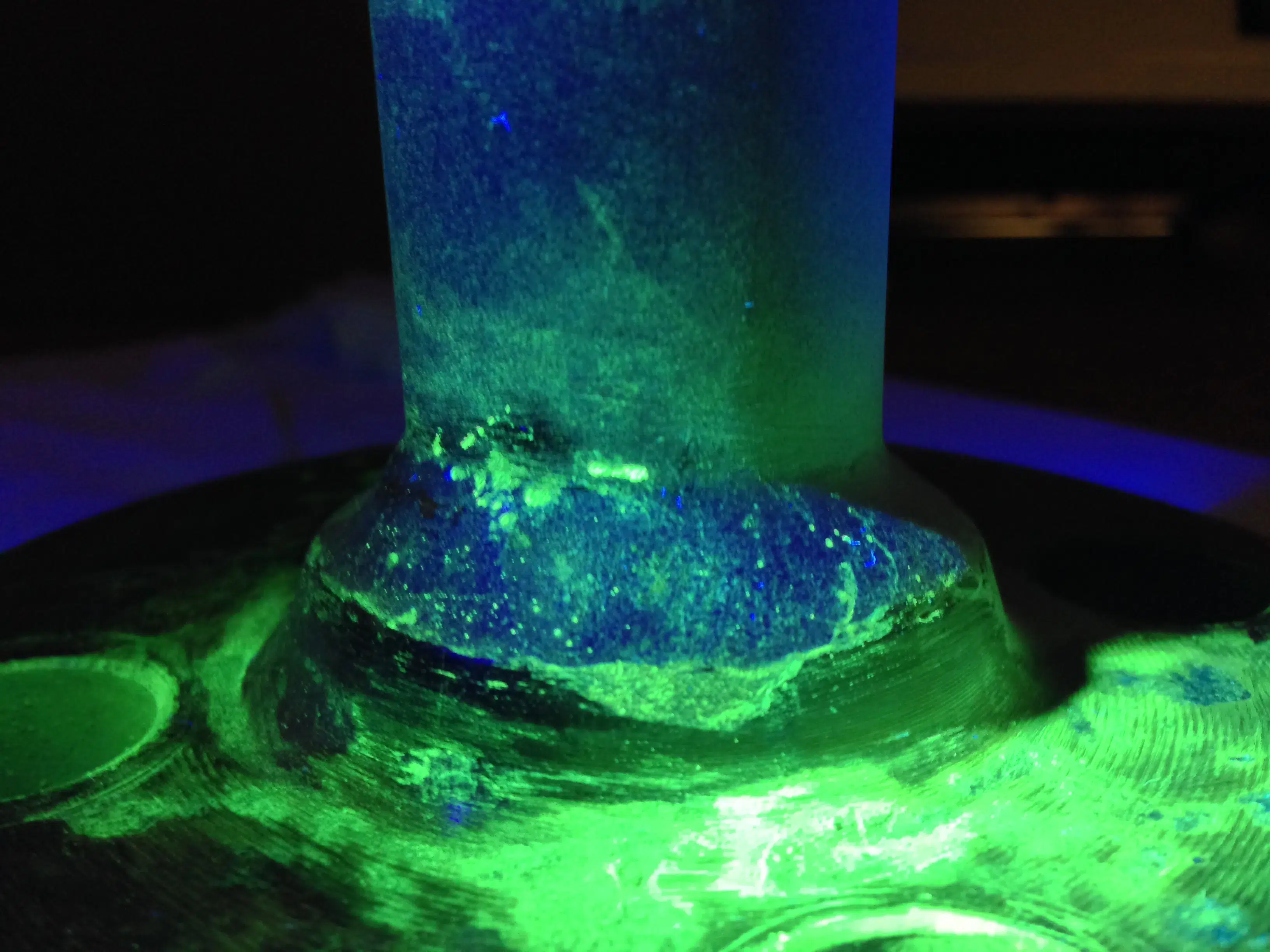

Application of developer: A developer is applied to the surface of the test object to draw the penetrant out of any defects and create a visible indication of the defects. The developer is allowed to dry for a specified time period.

Inspection: The surface of the test object is examined using a suitable light source, such as a UV light, to identify any indications of defects. The size, shape, and location of the indications are recorded and evaluated to determine the severity of the defects.

Overall, the process of performing a dye penetrant inspection involves carefully preparing the surface of the test object, applying and removing the penetrant, and using a developer to create a visible indication of any defects.

Log in to reply.