What is the role of integrity engineering in safety management?

Integrity engineering is a discipline that involves the design, assessment, and maintenance of systems and structures to ensure that they perform their intended function safely and reliably over their lifetime.

Integrity engineering plays a critical role in safety management, as it helps to ensure that systems and structures are designed and operated safely and reliably.

This includes identifying and mitigating potential failure modes and hazards, as well as implementing measures to prevent or detect potential failures.

What does integrity engineering involve?

Some specific ways in which integrity engineering contributes to safety management include:

- Risk assessment: Identifying potential hazards and failure modes, and evaluating their likelihood and consequences.

- Design for integrity: Ensuring that systems and structures are designed and built to withstand the loads and stresses they will encounter over their lifetime.

- Inspection and testing: Regularly inspecting and testing systems and structures to ensure they are in good condition and functioning properly.

- Maintenance: Implementing preventative and corrective maintenance to ensure that systems and structures continue to function safely and reliably.

- Repair and refurbishment: Repairing or replacing components that have failed or are no longer fit for purpose.

By addressing potential hazards and failure modes, integrity engineering helps to reduce the likelihood of accidents or failures occurring, which is critical for ensuring the safety of personnel and the environment.

Risk assessment

Risk assessment is a process used to identify and evaluate potential hazards and risks associated with a system, structure, or activity. It involves the systematic evaluation of the likelihood and consequences of potential failures or accidents, and the identification of measures to mitigate or manage these risks.

The purpose of risk assessment is to identify and prioritize potential hazards and risks, so that appropriate measures can be taken to prevent or mitigate them. This may include implementing controls to reduce the likelihood of a hazard occurring, or to limit the consequences if it does occur.

There are many different approaches to risk assessment, and the specific approach used will depend on the nature and complexity of the system or activity being evaluated. Some common methods used in risk assessment include:

- Hazard identification: Identifying the potential hazards and failure modes associated with a system or activity.

- Risk evaluation: Assessing the likelihood and consequences of each identified hazard, and determining the overall level of risk.

- Risk control: Identifying and implementing measures to reduce the likelihood or consequences of identified hazards.

Risk assessment is an important aspect of integrity engineering, as it helps to ensure that systems and structures are designed and operated safely and reliably. It is also an important aspect of safety management and risk management in many industries.

Design for integrity

Design for integrity is a process used to ensure that systems and structures are designed and built to withstand the loads and stresses they will encounter over their lifetime. This includes considering the potential failure modes and hazards associated with the system or structure, and implementing design features or measures to prevent or mitigate these risks.

Design for integrity is an important aspect of integrity engineering, as it helps to ensure that systems and structures are able to maintain their structural and functional integrity over their intended lifespan. It is also an important aspect of safety engineering, as it helps to reduce the likelihood of accidents or failures occurring.

There are several key considerations in design for integrity, including:

- Loads and stresses: Ensuring that the system or structure is designed to withstand the loads and stresses it will encounter during operation. This may include considering factors such as temperature, pressure, corrosion, fatigue, and impact.

- Materials selection: Choosing materials that are suitable for the intended application and operating conditions. This may involve considering factors such as strength, toughness, corrosion resistance, and fatigue resistance.

- Structural integrity: Ensuring that the system or structure is able to maintain its structural integrity under the expected loads and stresses. This may involve designing for structural redundancy or using materials with high strength-to-weight ratios.

- Safety factors: Incorporating margins of safety into the design to allow for uncertainties or unexpected loads or stresses. This may involve using materials with higher strength or using larger safety factors.

- Maintenance: Ensuring that the system or structure is designed for ease of maintenance and repair, to help ensure its long-term reliability.

Design for integrity is an interdisciplinary field that involves knowledge and skills from a range of engineering disciplines, as well as other areas such as materials science, structural engineering, and safety engineering.

Inspection and testing

Inspection and testing is a process used to evaluate the condition and performance of systems and structures to ensure that they are functioning properly and safely. This may involve visual inspection, non-destructive testing (NDT), or destructive testing (DT) to identify any issues or defects that may affect the integrity of the system or structure.

Inspection and testing is an important aspect of integrity engineering, as it helps to ensure that systems and structures are able to maintain their structural and functional integrity over their intended lifespan. It is also an important aspect of safety engineering, as it helps to identify and address any potential hazards or failure modes that may pose a risk to personnel or the environment.

There are many different methods and techniques used in inspection and testing, including:

- Visual inspection: Examining the surface of a system or structure using the naked eye, or with the aid of tools such as binoculars or magnifying glasses.

- Non-destructive testing (NDT): Evaluating the condition of a system or structure without causing any damage or alteration. This may include methods such as ultrasonic testing, radiographic testing, or magnetic particle inspection.

- Destructive testing (DT): Testing a system or structure by intentionally causing damage or alteration, in order to evaluate its performance or characteristics. This may include methods such as tensile testing or fatigue testing.

Inspection and testing is an interdisciplinary field that involves knowledge and skills from a range of engineering disciplines, as well as other areas such as materials science, structural engineering, and safety engineering.

Maintenance

Maintenance is the process of ensuring that systems and structures continue to function safely and reliably over their intended lifespan. This may involve preventative maintenance, which is carried out on a regular basis to prevent potential failures or degrade, or corrective maintenance, which is carried out to repair or replace components that have failed or are no longer fit for purpose.

Maintenance is an important aspect of integrity engineering, as it helps to ensure that systems and structures are able to maintain their structural and functional integrity over their intended lifespan. It is also an important aspect of safety engineering, as it helps to reduce the likelihood of accidents or failures occurring.

There are many different approaches to maintenance, including:

- Preventative maintenance: Regularly inspecting and maintaining systems and structures to prevent potential failures or degrade. This may include activities such as lubrication, cleaning, and tightening bolts.

- Predictive maintenance: Using sensors or other monitoring technologies to predict when maintenance may be needed, based on the condition or performance of the system or structure.

- Corrective maintenance: Repairing or replacing components that have failed or are no longer fit for purpose.

- Planned maintenance: Scheduling maintenance activities in advance, based on the expected lifespan or performance of components or systems.

- Emergency maintenance: Carrying out urgent repairs or replacements in response to unexpected failures or accidents.

Maintenance is an interdisciplinary field that involves knowledge and skills from a range of engineering disciplines, as well as other areas such as logistics, supply chain management, and safety engineering.

Repair and refurbishment

Repair and refurbishment is the process of repairing or replacing components of a system or structure that have failed or are no longer fit for purpose. This may involve repairing components that have been damaged or have worn out, or upgrading components to improve performance or extend the lifespan of the system or structure.

Repair and refurbishment is an important aspect of integrity engineering, as it helps to ensure that systems and structures are able to maintain their structural and functional integrity over their intended lifespan. It is also an important aspect of sustainability, as it can extend the useful life of a system or structure, reducing the need for new resources to be consumed.

There are many different approaches to repair and refurbishment, including:

- Repair: Restoring a component or system to its original condition by replacing or repairing damaged or worn parts.

- Refurbishment: Upgrading or modernizing a component or system to improve its performance or extend its lifespan. This may involve replacing components with newer or more efficient versions, or adding new features or capabilities.

- Retrofit: Modifying a system or structure to improve its performance or adapt it for a new purpose. This may involve replacing components, adding new features or capabilities, or adapting the system or structure to meet new regulations or standards.

Repair and refurbishment is an interdisciplinary field that involves knowledge and skills from a range of engineering disciplines, as well as other areas such as materials science, manufacturing, and sustainability.

What industries is integrity engineering relevant to?

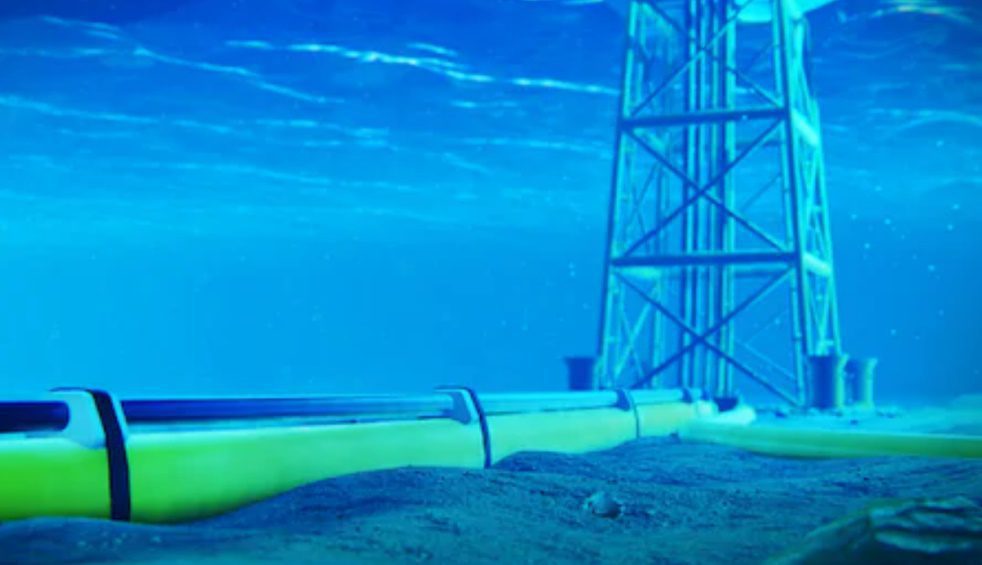

Integrity engineering is an important aspect of many industries, including oil and gas, aerospace, nuclear power, and transportation. It is also relevant to the design and maintenance of infrastructure such as bridges, buildings, and pipelines.

- International Council on Systems Engineering (INCOSE): https://www.incose.org/

- American Society for Quality (ASQ): https://asq.org/

- Society for Maintenance and Reliability Professionals (SMRP): https://www.smrp.org/

- American Society of Mechanical Engineers (ASME): https://www.asme.org/

- American Society of Civil Engineers (ASCE): https://www.asce.org/

These organizations provide information and resources related to integrity engineering, including standards, guidelines, best practices, and training opportunities.

Responses