API 570 Course Notes

API 570 PIPING INSPECTOR

PREPARATORY COURSE

COURSE NOTES

API 570 PIPING INSPECTOR

PREPARATORY COURSE

TABLE OF CONTENTS

CHAPTER DESCRIPTION

1. Overwiew of API 570

2. Overview of RP- API 574

3. Overwiew of ASME B 31.3

4. Overview of ASME B 16.5

- Overview of ASME Section IX

6. Overview of ASME Section V

CHAPTER-1

570 PIPING INSPECTION CODE

- INTRODUCTION TO API-570

1.1 SCOPE

-

-

- Coverage :

-

API 570 covers inspection, repair, alteration, and rerating procedures for metallic piping systems that have been in service.

Repair ; The work necessary to restore a piping system to a condition suitable for safe operation at the design condition.

Alterations : A physical change in any component that has design implications affecting the pressure containing capability or flexibility of a piping system beyond the scope of its design.

Rerating : A change in either or both the design temperature or the maximum allowable working pressure of a piping system. A rerating may consist of an increase, a decrease, or a combination of both. Rerating below original design conditions is a means to provide increased corrosion allowance.

-

-

- LIMITATIONS :

-

API 570 shall not be used as a substitute for the original construction requirements governing a piping system before it is placed in service.

-

- SPECIFIC APPLICATIONS

1.2.1 Included Fluid Services :

API 570 applies to piping systems for process fluids, hydrocarbons, and similar flammable or toxic fluid services, such as the following.

-

- Raw, intermediate, and finished petroleum products.

- Raw intermediate, and finished chemical products.

- Catalyst lines.

- Hydrogen, natural gas, fuel gas, and flare systems.

- Sour water and hazardous waste streams above threshold limits, as defined by jurisdictional regulations.

- Hazardous chemicals above threshold limits, as defined by jurisdictional regulations.

- Excluded and Optional Piping Systems :

The fluid services and classes of piping systems listed below are excluded from the specific requirements of API 570 but may be included at the owner’s or user’s (owner/user’s) option.

- Fluid services that are excluded or optional include the following.

- Hazardous fluid services below threshold limits, as defined by jurisdictional regulations.

- Water (including fire protection systems) , steam, steam-condensate, boiler feed water, and Category D fluid services, as defined in ASME B 31.3

- Classes of piping systems that are excluded or optional are as follows :

- Piping systems on movable structures covered by jurisdictional regulations, including piping systems on trucks, ships, barges, and other mobile equipment.

- Piping systems that are an integral part or component or rotating or reciprocating mechanical devices, such as pumps, compressors, turbines, generators, engines, and hydraulic or pneumatic cylinders where the primary design considerations and/or stresses are derived from the functional requirements of the device.

- Internal piping or tubing of fired heaters and boilers, including tubes, tube headers, return bends, external crossovers, and manifolds.

- Pressure vessels, heaters, furnaces, heat exchangers, and other fluid handling or processing equipment, including internal piping and connections for external piping.

- Plumbing, sanitary sewers, process waste sewers, and storm sewers.

- Piping or tubing with an outside diameter not exceeding that of NPS ½.

- Nonmetallic piping and polymeric or glass-lined piping.

- DEFINITIONS

2.1 APPLICATION CODE :

The code, code section, or other recognized and generally accepted engineering standard or practice to which the piping system was built or which is deemed by the owner or user or the piping engineer to be most appropriate for the situation, including but not limited to the latest edition of ASME B 31.3

2.2 AUTHORIZED INSPECTION AGENCY :

Defined as any of the following. :

- The inspection organization of the jurisdiction in which the piping system is used.

- The inspection organization of an insurance company that is licensed or registered to write insurance for piping systems.

- An owner or user of piping systems who maintains an inspection organization for activities relating only to his equipment and not for piping systems intended for sale or resale.

- An independent inspection organization employed by or under contract to the owner or user of piping systems that are used only by the owner or user and not for sale or resale.

- An independent inspection organization licensed or recognized by the jurisdiction in which the piping system is used and employed by or under contract to the owner or user.

2.3 AUTHORIZED PIPING INSPECTOR :

An employee of an authorized inspection agency who is qualified and certified to perform the functions specified in API 570. A nondestructive (NDE) examiner is not required to be an authorized piping inspector. Whenever the term inspector is used in API 570, it refers to an authorized piping inspector.

2.4 AUXILLARY PIPING :

Instrument and machinery piping, typically small-bore secondary process piping that can be isolated from primary piping systems. Examples include flush lines, seal oil lines, analyzer lines, balance lines, buffer gas lines, drains and vents.

2.5 CUI :

Corrosion under insulation, including stress corrosion cracking under insulation.

2.6 DEADLEGS :

Components of a piping system that normally have no significant flow. Examples include the following : blanked branches, lines with normally closed block valves, lines with one end blanked, pressurized dummy support legs, stagnant control valve bypass piping, spare pump piping, level bridles, relief valve inlet and outlet header piping, pump trim bypass lines, high point vents, sample points, drains, bleeders, and instrument connections.

2.7 DEFECT :

An imperfection of a type or magnitude exceeding the acceptable criteria.

2.8 EXAMINER :

A person who assists the inspector by performing specific nondestructive examination (NDE) on piping system components but does not evaluate the results of those examinations in accordance with API 570, unless specifically trained and authorized to do so by the owner or user. The examiner need not be qualified in accordance with API 570.

2.9 HOLD POINT :

A point in the repair or alteration process beyond which work may not proceed until the required inspection has been performed and documented.

2.10 IMPERFECTIONS :

Flaws or other discontinuities noted during inspection that may be subject to acceptance criteria during an engineering and inspection analysis.

2.11 INDICATION :

A response or evidence resulting from the application of a nondestructive evaluation technique.

2.12 INJECTION POINT :

Locations where relatively small quantities of materials are injected into process streams to control chemistry or other process variables. Injection points do not include locations where two process streams join.

2.13 IN-SERVICE :

Refers to piping systems that have been placed in operation, as opposed to new construction prior to being placed in service.

2.14 INSPECTOR :

An authorized piping inspector.

2.15 LEVEL BRIDLE :

A level gauge glass piping assembly attached to a vessel.

-

- MAXIMUM ALLOWABLE WORKING PRESSURE (MAWP)

The maximum internal pressure permitted in the piping system for continued operation at the most severe condition of coincident internal or external pressure and temperature (maximum and minimum) expected during service. It is the same as the design pressure, as defined in ASME B 31.3 and other code sections, and is subject to the same rules relating to allowances for variations of pressure or temperature or both.

2.17 ON-STREAM :

Piping containing any amount of process fluid.

2.18 PIPING CIRCUIT :

A section of piping that has all points exposed to an environment of similar corrosivity and that is of similar design conditions and construction material.

2.19 PRIMARY PROCESS PIPING :

Process piping in normal, active service that cannot be valved off or, if it were valved off, would significantly affect unit operability. Primary process piping normally includes all process piping greater than NPS 2.

2.20 REPAIR ORGANIZATION :

Any of the following :

- An owner or user of piping systems who repairs or alters his or her own equipment in accordance with API 570.

- A contractor whose qualifications are acceptable to the owner or user of piping systems and who makes repairs or alterations in accordance with API 570.

- One who is authorized by, acceptable to, or otherwise not prohibited by the jurisdiction and who makes repairs in accordance with API 570.

2.21 SECONDARY PROCESS PIPING :

Small-bore (less than or equal to NPS 2) process piping downstream of normally closed block valves.

2.22 SMALL-BORE PIPING (SBP) :

Piping that is less than or equal to NPS 2.

2.23 SOIL-TO AIR (S/A) INTERFACE :

An area in which external corrosion may occur on partially buried pipe. The zone of the corrosion will vary depending on factors such as moisture, oxygen content of the soil, and operating temperature. The zone generally is considered to be from 12 inches (305 mm) below to 6 inches (150 mm) above the soil surface. Pipe running parallel with the soil surface that contacts the soil is included.

2.24 SPOOL :

A section of piping encompassed by fianges or other connecting fittings such as unions.

2.25 TEMPER EMBRITTLEMENT :

A loss of ductility and notch toughness in susceptible low-alloy steels, such as 1 ¼ Cr and 2 ¼ Cr, due to prolonged exposure to high-temperature service [700o F-1070oF (370oC-575oC) ]

2.26 TEMPORARY REPAIRS :

Repairs made to piping systems in order to restore sufficient integrity to continue safe operation until permanent repairs can be scheduled and accomplished within a time period acceptable to the inspector or piping engineer.

2.27 TEST POINT :

An area defined by a circle having a diameter not greater than 2 inches (50 mm) for a line diameter not exceeding 10 inches (250 mm) or not greater than 3 inches (75 mm) for larger lines. Thickness readings may be averaged within this area. A test point shall be within a thickness measurement location.

2.28 THICKNESS MEASUREMENT LOCATIONS (TMLs) :

Designated areas on piping systems where periodic inspections and thickness measurement’s are conducted.

2.29 WFMT :

Wet fluorescent magnetic -particle testing.

- OWNER/ INSPECTION ORGANISATION

- API AUTHORIZED PIPING INSPECTOR QUALIFICATION AND CERTIFICATION :

Authorized piping inspectors shall have education and experience in accordance with Appendix A of this inspection code. Authorized piping inspectors shall be certified by the American Petroleum Institute in accordance with the provisions of Appendix A. Whenever the term inspector is used in this document, it refers to an authorized piping inspector.

3.2 RESPONSIBILITIES :

3.2.1 An owner/user organization is responsible for developing, documenting, implementing, executing, and assessing piping inspection systems and inspection procedures that will meet the requirements of this inspection code. These systems and procedures will be contained in a quality assurance inspection manual or written procedures and shall include :

- Organization and reporting structure for inspection personnel.

- Documenting and maintaining inspection and quality assurance procedures.

- Documenting and reporting inspection and test results.

- Corrective action for inspection and test results.

- Internal auditing for compliance with the quality assurance inspection manual.

- Review and approval of drawings, design calculations, and specifications for repairs, alterations, and re-ratings.

- Ensuring that all jurisdictional requirements for piping inspection, repairs, alterations, and re-rating are continuously met.

- Reporting to the authorized piping inspector any process changes that could affect piping integrity.

- Training requirements for inspection personnel regarding inspection tools, techniques, and technical knowledge base.

- Controls necessary so that only qualified welders and procedures are used for all repairs and alterations.

- Controls necessary so that only qualified nondestructive examination (NDE) personnel and procedures are utilized.

- Controls necessary so that only materials conforming to the applicable section of the ASME Code are utilized for repairs and alterations.

- Controls necessary so that all inspection measurement and test equipment are properly maintained and calibrated.

- Controls necessary so that the work of contract inspection or repair organizations meet the same inspection requirements as the owner/user organization.

- Internal auditing requirements for the quality control system for pressure-relieving devoices.

3.2.2 PIPING ENGINEER :

The piping engineer is responsible to the owner/user for activities involving design, engineering review, analysis, or evaluation of piping systems covered by API 570.

3.2.3 REPAIR ORGANIZATION :

The repair organization shall be responsible to the owner/user and shall provide the materials, equipment, quality control, and workmanship necessary to maintain and repair the piping systems in accordance with the requirements of API 570.

3.2.4 AUTHORIZED PIPING INSPECTOR :

When inspections, repairs, or alterations are being conducted on piping systems, an API authorized piping inspector shall be responsible to the owner/user for determining that the requirements of API 570 on inspection, examination, and testing are met, and shall be directly involved in the inspection activities. The API authorized piping inspector may be assisted in performing visual inspections by other properly trained and qualified individuals, who may or may not be certified piping inspectors. Personnel performing nondestructive examinations shall meet the qualifications identified in 3.12, but need not be API authorized piping inspectors. However, all examination results must be evaluated and accepted by the API- authorized piping inspector.

3.2.5 OTHER PERSONNEL :

Operating, maintenance, or other personnel who have special knowledge or expertise related to particular piping systems shall be responsible for promptly making the inspector or piping engineer aware of any unusual conditions that may develop and for providing other assistance, where appropriate.

INSPECTION AND TESTING

- RISK BASED INSPECTION (RBI)

RBI is identifying and evaluating potential degradation consequence of which may be a risk of creation of unsafe conditions (for plant, process, people ) and / or likely failure of component.

RBI involves following essential elements :

- Expected type of degradation i.e. type of degradation process as well as environmental factors may cause.

- Likely areas affected i.e. identifying the most prone areas and possible locations to look for the type of degradation.

- Measurement of degradation i.e. quantifying the amount of degradation.

- Assessment and evaluation i.e. analysis of degradation and likely consequences.

- Above all effectiveness of inspection practices, tools techniques employed have a great bearing of success of RBI program.

- PREPARATION :

Prior to actual inspection proper preparation and safety precautions are essential particularly if components are to be inspected internally. This essentially involves –

- Isolating and segregating the piping system, installing blanks (blids) etc.

- Removal of harmful liquids, gases, vapors, flushing out and purging to bring down residual content to safe levels.

- Obtain suitable permissions to work i.e. cold work permit (CWP), Hotwork Permits (HWP) etc.

- Protective equipment, clothing, masking as required.

- Safety equipments shall be subjectto operating facilities safety requirements. (e. g. electrical requirements, flame arrester etc.)

3. INSPECTION FOR SPECIFIC TYPES OF CORROSION AND CRACKING :

Each owner/ user should provide specific attention to the need for inspection of piping system that are susceptible to the following specific types & areas of deterioration :

- Injection points.

- Deadlegs.

- Corrosion under insulation ( CUI ).

- Soil-to-air (S/A ) interfaces. .

- Services specific & localized corrosion.

- Erosion &c orrosion/erosion.

- Environmental cracking.

- Corrosion beneath linings & deposits.

- Fatigue cracking .

- Creep cracking.

- Brittle fracture.

- Freeze damage.

3.1 Injection Points : Injection points are sometimes subject to accelerated or localized corrosion.

When designating an injection point circuit for the purposes of inspection, the recommended upstream limit of the injection point circuit is a minimum of 12 inches (300) or three pipe diameters upstream of the injection point, whichever is greater. The recommended downstream limit of the injection point circuit is the seconed change in flow direction past the injection point, or 25 feet (7.6 m) beyond the first change in flow direction, whichever is less. In some cases, it may be more appropriate to extend this circuit to the next piece of pressure equipment.

Guide Lines For Selecting TMLS :

- Establish TMLs on appropriate fittings within the injection point circuit.

- Establish TMLs on the pipe wall at the location of expected pipe wall impingement of injected fiuid.

- TMLs at intermediate locations along the longer straight piping within the injection point circuit may be required.

d. Establish TMLs at both the upstream & downstream limit of the injection point circuit.

The preferred methods of inspecting injection points are radiography and/or ultrasonics, as appropriate, to establish the minimum thickness at each TML.

For some applications, it is beneficial to remove piping spools to facilitate a visual inspection of the inside surface. However, thickness measurements will still be required to determine the remaining thickness.

During periodic scheduled inspections, more extensive inspection should be applied to an area beginning 12 inches (300 mm) upstream of the injection nozzle and continuing for at least ten pipe diameters downstream of the injection point. Additionally, measure and record the thickness at all TMLs within the injection point circuit.

-

- Deadlegs : The corrosion rate in deadlegs can vary significantly from the adjacent active piping. The inspector should monitor wall thickness on selected deadlegs, including both the stagnant end and at the connection to an active line. In hot piping systems, the high-point area may corrode due to convective currents set up in the deadlegs. Consideration should be given to removing deadlegs that serve no further process purpose.

- Corrosion Under Insulation : External inspection of insulated piping systems should include a review of the integrity of the insulation system for conditions that cold lead to corrosion under insulation (CUI) and for signs of ongoing CUI. Sources of moisture may include rain, water leaks, condensation and deluge systems. The most common forms of CUI are localized corrosion of carbon steel and chloride stress corrosion cracking of austenitic stainless steels.

Below are the guidelines for indentifying potential CUI areas for inspection. The extent of a CUI inspection program may vary depending on the local climate – warmer marine locations may require a very active program; whereas cooler, drier, mid-continent locations may not need as extensive a program.

3.4 Insulated Piping Systems Susceptible to CUI : Certain areas and types of piping systems are potentially more susceptible to CUI, including the following :

- Areas exposed to mist overspray from cooling water towers.

- Areas exposed to steam vents.

- Areas exposed to deluge systems

- Areas subject to process spills, ingress of moisture , or acid vapors.

- Carbon steel piping systems, including those insulated for personnel protection, operation between 250 F- 2500 F (-40C-1200 C). CUI is particularly aggressive where operating temperatures cause frequent or continuous condensation and re-evaporation of atmospheric moisture.

- Carbon steel piping systems that normally operate in-service above 2500 F (1200C) but are in intermittent service.

- Deadlegs and attachments that protrude from insulated piping and operate at a different temperature than the operating temperature of the active line.

- Austenitic stainless steel piping systems operating 1500F- 4000 F (650C-2040C). (These systems are susceptible to chloride cracking. )

- Vibrating piping systems that have a tendency to inflict damage to insulation jacketing providing a path for water ingress.

- Steam traced piping systems that may experience tracing leaks, especially at tubing fitting beneath the insulation.

- Piping systems with deteriorated coatings and/or wrappings.

- Common Locations on Piping Systems Susceptible to CUI : The areas of piping systems listed above may have specific locations within them that are more susceptible to CUI, including the following :

- All penetrations or breaches in the insulation jacketing systems, such as :

- Deadlegs (vents, drains, and other similar items)

- Pipe hangers and other supports.

- Valves and fittings (irregular insulation surfaces)

- Bolted-on pipe shoes.

- Steam tracer tubing penetrations.

- Termination of insulation at flangers and other piping components.

- Damaged or missing insulation jacketing

- Insulation jacketing seams located on the top of horizontal piping or imporperty lapped or sealed insulation jacketing.

- Termination of insulation in a vertical pipe.

- Caulking that has hardened, has separated, or is missing.

- Bulges or staining of the insulation or jacketing system or missing bands (Bulges may indicate corrosion product buildup).

- Low points in piping systems that have a known breach in the insulation system, including low points in long unsupported piping runs.

- Carbon or low-alloy steel flanges, bolting, and other components under insulation in high-alloy piping systems.

- Soil-to–Air Interface : Soil-to-air (S/A) interfaces for buried piping without adequate cathodic protection shall be included in scheduled external piping inspections.)

Thickness measurements and excavation may be required to assess whether the corrosion is localized to the S/A interface or extends to the buried system.

Thickness readings at S/A interfaces may expose the metal and accelerate corrosion if coatings and wrappings are not properly restored.

If the buried piping is uncoated at grade, consideration should be given to excavating 6 inches to 12 inches (150 mm to 300 mm) deep to assess the potential for hidden damage.

3.7 Service Specific & Localized Corrosion : An effective inspection program includes the following three elements, which help identify the potential for service specific & localized corrosion & select appropriate TMLs :

a. An inspector with knowledge of the service & where corrosion is

likely to occur.

- Extensive use of nondestructive examination (NDE).

- Communication from operating personnel when process upsets occur that may affect corrosion rates.

- Dew point corrosion in condensing streams.

- Mixed grades of carbon steel piping in hot corrosive oil service (450 deg F [230 deg]C) or higher temperature & sulfur content in the oil greater than 0.5 percent by weight.

- Non silicon kiled steel pipe, such as A-53 & API 5L, may corrode at higher rates than does silicon killed steel pipe, such as A-106 especially in high –temperature sulfidic environments.

- Erosion & corrosion/ erosion : Erosion can be defined as the removal of surface material by the action of numerous individual impacts of solid or liquid particles. It can be characterized by grooves, rounded holes, waves, & vallys in a directional pattern. Erosion usually occurs in areas of turbulent flow, such as at change of direction in a piping system or downstream of control valves where vaporization may take place.

- Erosion damage is usually increased in streams with large quantities of solid or liquid particles flowing at high velocities. A combination of corrosion & erosion ( corrosion/erosion )results in significantly greater metal loss than can be expected from corrosion occurs at high velocity & high turbulence areas.

Examples of places to inspect include the following :

- Downstream of control valves, especially when flashing is

occurring.

- Downstream of orifices.

- Downstream of pump discharges.

- At any point of flow direction change, such as the inside & outside radii of elbows.

- Environmental Cracking : Piping system construction materials are normally selected to resist the various forms of stress corrosion cracking (SCC). However, some piping system may be susceptible to environmental cracking due to upset process conditions, CUI unanticipated condensation, or exposure to wet hydrogen sulfide or carbonates.

Examples of environmental cracking include :

a. Chloride SCC of austenitic stainless steels due to moisture &

chlorides under insulation, under deposits , under gaskets, or in crevices.

- Caustic SCC ( sometimes known as caustic embrittlement ).

- Scc in environments where wet hydrogen sulfide exists, such as systems containing sour water.

- Hydrogen blistering & hydrogen induced cracking ( HIC ) damage .

4. CORROSION BENEATH LININGS AND DEPOSITS :

4.1 General:

If external or internal coatings, refractory linings, and corrosion-resistant linings are in good condition and there is no reason to suspect a deteriorated condition behind them, it is usually not necessary to remove them for inspection of the piping system.

The linings should be inspected for separation, breaks, holes, and blisters. If any of these conditions are noted, it may be necessary to remove portions of the internal lining to investigate the effectiveness of the lining and the condition of the metal piping beneath the lining.

Corrosion beneath refractory linings can result in separation and bulging of the refractory. If bulging or separation of the refractory lining is detected, portions of the refractory may be removed to permit inspection of the piping beneath the refractory.

4.2. FATIGUE CRACKING :

Fatigue cracking of piping systems may result from excessive cyclic stresses that are often well below the static yield strength of the material. The onset of low-cycle fatigue cracking is often directly related to the number of heat-up and cool-down cycles experienced. Excessive piping system vibration (such as machine or flow-induced vibrations) also can cause high-cycle fatigue damage.

Fatigue cracking can typically be first detected at points of high-stress intensification such as branch connections. Locations where metals having different coefficients of thermal expansion are joined by welding may be susceptible to thermal fatigue. Preferred NDE methods of detecting fatigue cracking include liquid-penetrant testing (PT) or magnetic-particle testing (MT). Acoustic emission also may be used to detect the presence of cracks that are activated by test pressures of stresses generated during the test.

It is important that the owner/user and the inspector understand that fatigue cracking is likely to cause piping failure before it is detected with any NDE methods. Of the total number of fatigue cycles required to produce a failure, the vast majority are required to initiate a crack and relatively fewer cycles are required to propagate the crack to failure. Therefore, proper design and installation in order to prevent the initiation of fatigue cracking are important.

4.2.12 CREEP CRACKING :

Creep is dependent on time, temperature, and stress. Cracking is accelerated by creep and fatigue interaction when operating conditions in the creep range are cycle. If excessive temperatures are encountered, mechanical property and microstructural changes in metals also may take place.

NDE methods of detecting creep cracking include liquid-penetrant testing, magnetic-particle testing, ultrasonic testing, radiographic testing, and in-situ metallography. Acoustic emission testing also may be used to detect the presence of cracks that are activated by test pressures or stresses generated during the test.

4.2.13 BRITTLE FRACTURE :

Carbon low-alloy, and other ferritic steels may be susceptible to brittle failure at or below ambient temperatures. Brittle fracture usually is not a concern with relatively thinwall piping. Most brittle fractures have occurred on the first application of a particular stress level (that is, the first hydrotest or overload) unless critical defects are introduced during service. The potential for a brittle failure shall be considered when rehydrotesting.

4.2.14 FREEZE DAMAGE :

At subfreezing temperatures, water and aqueous solutions in piping systems may freeze and cause failure because of the expansion of these materials. After unexpectedly severe freezing weather, it is important to check for freeze damage to exposed piping components before the system thaws. If rupture has occurred, leakage may be temporarily prevented by the frozen fluid. Low points, riplegs, and deadlegs of piping systems containing water should be carefully examined for damage.

4.3 TYPES OF INSPECTION AND SURVEILLANCE :

Different types of inspection and surveillance are appropriate depending on the circumstances and the piping system . These include the following :

- Internal visual inspection.

- Thickness measurement inspection.

- External visual inspection.

- Vibrating piping inspection

- Supplemental inspection.

4.3.1 INTERNAL VISUAL INSPECTION :

Internal visual inspections are not normally performed on piping. When possible and practical, internal visual inspections may be scheduled for systems such as large-diameter transfer lines, ducts, or other large-diameter piping systems. Such inspections are similar in nature to pressure vessel inspections and should be conducted with methods and procedures similar to those outlined in API 510.

4.3.2 THICKNESS MEASUREMENT INSPECTION :

A thickness measurement inspection is performed to determine the internal condition and remaining thickness of the piping components. Thickness measurements may be obtained when the piping system is in or out of operation and shall be performed by the inspector or examiner.

4.3.3 EXTERNAL VISUAL INSPECTION :

In addition to these scheduled external inspections that are documented in inspection records, it is beneficial for personnel who frequent the area to report deterioration or changes to the inspector.

4.3.4 SUPPLEMENTAL INSPECTION :

Other inspections may be scheduled as appropriate or necessary. Examples of such inspections include periodic use of radiography and/or thermography to check for fouling or internal plugging, thermography to check for hot spots in refractory lined systems, or inspection for environmental cracking. Acoustic emission, acoustic leak detection, and thermography can be used or remote leak detection and surveillance. Ultrasonics and/or radiography can be used for detecting localized corrosion.

4.4 THICKNESS MEASUREMENT LOCATIONS :

4.4.1 GENERAL :

Thickness measurement locations (TML’s) are specific areas along the piping circuit where inspections are to be made. The nature of the TML varies according to its location in the piping system. The selection of TML’s shall consider the potential for localized corrosion and service-specific corrosion as described in 5.3

4.4.2 TML MONITORING :

Each piping system shall be monitored by taking thickness measurements at TML’s. Piping circuits with high potential consequences if failure should occur and those subject to higher corrosion rates or localized corrosion will normally have more TMLs and be monitored more frequently.

The minimum thickness at each TML can be located by ultrasonic scanning or radiography. Electromagnetic techniques also can be used to identify thin areas that may then be measured by ultrasonics or radiography. When accomplished with ultrasonics, scanning consists of taking several thickness measurement at the TML searching for localized thinning. The thinnest reading or an average of several measurement readings taken within the area of a test point shall be recorded and used to calculate corrosion rates, remaining life, and the next inspection date.

Where appropriate, thickness measurements should include measurements at each of the four quadrants on pipe and fittings, with special attention to the inside and outside radius of elbows and tees where corrosion/erosion could increase corrosion rates. As a minimum, the thinnest reading and its location shall be recorded.

TML’s should be established for areas with continuing CUI, corrosion at S/A interfaces, or other locations of potential localized corrosion as well as for general uniform corrosion.

TMLs should be marked on inspection drawings and on the piping system to allow repetitive measurements at the same TMLs. This recording procedure provides data for more accurate corrosion rate determination.

4.4.3 TML SELECTION :

In selecting or adjusting the number and locations of TMLs the inspector should take unto account the patterns of corrosion that would be expected and have been experienced in the process unit.

More TMLs should be selected for piping systems with any of the following characteristics :

- Higher potential for creating a safety or environmental emergency in the event of a leak.

- Higher expected or experienced corrosion rates.

- Higher potential for localized corrosion.

- More complexity in terms of fittings, branches, deadlegs injection points, and other similar items.

- Higher potential for CUI

Fewer TMLs can be selected for piping systems with any of the following three characteristics :

- Low potential for creating a safety or environmental emergency in the event of a leak.

- Relatively non-corosive piping systems.

- Long, straight-run piping systems.

TMLs can be eliminated for piping systems with either of the following two characteristics :

- Extremely low potential for creating a safety or environmental emergency in the event of a leak.

- Non-corrosive systems, as demonstrated by history or similar service, and systems not subject to changes that could cause corrosion.

4.5 THICKNESS MEASUREMENT METHODS :

Ultrasonic thickness measuring instruments usually are the most accurate mean for obtaining thickness measurements on installed pipe larger than NPS 1. Radiographic profile techniques are preferred for pipe diameters of NPS 1 and smaller. Radiographic profile techniques may be used for locating areas to be measured, particularly in insulted systems or where non-uniform or localized corrosion is suspected.

Where practical , ultrasonics can then be used to obtain the actual thickness of the areas to be recorded. Following ultrasonic readings at TMLs, proper repair of insulation and insulation weather coating is recommended to reduce the potential for CUI.

Radiographic profile techniques, which do not require removing insulation, may be considered as an alternative.

When ultrasonic measurements are taken above 150oF (65oC), instruments, couplants, and procedures should be used that will result in accurate measurements at the higher temperatures.

Measurements should be adjusted by the appropriate temperature correction factor.

- Improper instrument calibration.

- External coatings or scale.

- Excessive surface roughness.

- Excessive “rocking” of the probe (on the curved surface)

- Subsurface material flaws, such as laminations.

- Temperature effects [at temperatures above 150oF (65oC)]

- Small flaw detector screens.

- Thickness of less than 1/8 inch (3.2 mm) for typical digital thickness gauges.

In addition, it must be kept in mind that the pattern of corrosion can be non-uniform.

For corrosion rate determinations to be valid, it is important that measurements on the thinnest point be repeated as closely as possible to the same location. Alternatively, the minimum reading or an average of several readings at a test point may be considered.

When piping systems are out of service, thickness measurements may be taken through openings using calipers. Calipers are useful in determining approximate thicknesses of castings, forgings, and valve bodies, as well as pit depth approximations from CUI on pipe.

Pit depth measuring devices also may be used to determine the depth of localized metal loss.

4.6 PRESSURE TESTING OF PIPING SYSTEMS :

Pressure tests are not normally conducted as part of a routine inspection. Exceptions to this include requirements of local jurisdictions, after welded alterations or when specified by the inspector or piping engineer. When they are conducted , pressure tests shall be performed in accordance with the requirements of ASME B 31.3

If a pressure test is to be maintained for a period of time and the test fluid in the system is subject to thermal expansion, precautions shall be taken to avoid excessive pressure.

When a pressure test is required, it shall be conducted after any heat treatment.

A pneumatic pressure test may be used when it is impracticable to hydrostatically test due to temperature, structural, or process limitations. However, the potential risks to personnel and property of pneumatic testing shall be considered when carrying out such a test. As a minimum, the inspection precautions contained in ASME B 31.3 shall be applied in any pneumatic testing.

During a pressure test, where the test pressure will exceed the set pressure of the safety valve on a piping system, the safety relief valve or valves should be removed or blanked for the duration of the test. As an alternative, each valve disk must be held down by a suitably designed test clamp.

The application of an additional load to the valve spring by turning the adjusting screw is not recommended. Other appurtenances that are incapable of withstanding the test pressure, such as gage glasses, pressure gages, expansion joints, and rupture disks, should be removed or blanked. Lines containing expansion joints that cannot be removed or isolated may be tested at a reduced pressure in accordance with the principles of ASME B 31.3. If block valves are used to isolate a piping system for a pressure test, caution should be used to not exceed the permissible seat pressure as described in ASME B 16.34 or applicable valve manufacturer data.

Upon completion of the pressure test, pressure relief devices of the proper settings and other appurtenances removed or made inoperable during the pressure test shall be reinstalled or reactivated.

4.7 MATERIAL VERIFICATIONS AND TRACEABILTY :

During repairs or alterations of low- to high alloy piping systems, the inspector shall verify the installation of the correct new materials. At the discretion of the owner/user or the inspector, this verification can be either by 100 percent checking or testing in certain critical situations or by sampling a percentage of the materials.

Testing can be accomplished by the inspector or the examiner with the use of suitable portable methods, such as chemical spot testing, optical spectrographic analyzers, or X-ray fluorescent analyzers. Checking can involve verifying test reports on materials, markings on piping components and bolting, and key dimensions.

If a piping system component should fail because an incorrect material was inadvertently substituted for the proper piping material, the inspector shall consider the need for further verification of existing piping materials.

The extent of further verification will depend upon circumstances such as the consequences of failure and the likelihood of further material errors.

4.8 INSPECTION OF VALVES :

Normally, thickness measurements are not routinely taken on valves in piping circuits. The body of a valve is normally thicker than other piping components for design reasons. However, when valves are dismantlted for servicing and repair, the shop should be attentive to any unusual corrosion patterns or thinning and, when noted, report that information to the inspector.

If gate valves are known to be or are suspected of being exposed to corrosion/erosion, thickness readings should be taken between the seats, since this is an area of high turbulence and high stress.

Control valves or other throttling valves, particularly in high pressure drop-and-slurry services, can be susceptible to localized corrosion/erosion of the body downstream of the orifice. If such metal loss is suspected, the valve should be removed from the line for internal inspection. The inside of the downstream mating flange and piping also should be inspected for local metal loss.

Critical check valves should be visually and internally inspected to ensure that they will stop flow reversals.

An example of a critical check valve may be the check valve located on the outlet of a multistage, high head hydro-processing charge pump. Failure of such a check valve to operate correctly could result in over pressuring the piping during a flow reversal. The normal visual inspection method should include :

- Checking to insure that the flapper is free to move, as required, without excessive looseness from wear.

- The flapper stop should not have excessive wear. This will minimize the likelihood that the flapper will move past the top dead central position and remain in an open position when the check valve is mounted in a vertical position.

- The flapper nut should be secured to the flapper bolt to avoid backing off in service.

Leak checks of critical check valves are normally not required.

4.9 INSPECTION OF WELDS IN- SERVICE :

Inspection for piping weld quality is normally accomplished as a part of the requirements for new construction, repairs, or alterations. However, welds are often inspected for corrosion as part of a radiographic profile inspection or as part of internal inspection. When preferential weld corrosion is noted, additional welds in the same circuit or system should be examined for corrosion.

If the noted imperfections are a result of original weld fabrication, inspection and/or engineering analysis is required to assess the impact of the weld quality on piping integrity. This analysis may be one or more of the following

- Inspector judgment.

- Certified welding inspector judgment.

- Piping engineer judgment.

- Engineering fitness-for-service analysis.

Issues to consider when assessing the quality of existing welds include the following

- Original fabrication inspection acceptance criteria.

- Extent, magnitude, and orientation of imperfections.

- Length of time in-service.

- Operating versus design conditions.

- Presence of secondary piping stresses (residual and thermal)

- Potential for fatigue loads (mechanical and thermal).

- Primary or secondary piping system.

- Potential for impact or transient loads.

- Potential for environmental cracking.

- Weld hardness.

In many cases for in-service welds, it is not appropriate to use the random or spot radiography acceptance criteria for weld quality in ASME B 31.3 These acceptance criteria are intended to apply to new construction on a sampling of welds, not just the welds examined, in order to assess the probable quality of all welds (or welders) in the system.

Some welds may exist that will not meet these criteria but will still perform satisfactorily in service.

4.10 INSPECTION OF FLANGED JOINTS :

The markings on a representative sample of newly installed fasteners and gaskets should be examined to determine whether they meet the material specification. The markings are identified in the applicable ASME and ASTM standards. Questionable fasteners should be verified or renewed.

Fasteners should extend completely through their nuts. Any fastener failing to do so is considered acceptably engaged if the lack of complete engagement is not more than one thread.

Flanged and valve bonnet joints should be examined for evidence of leakage, such as stains, deposits, or drips. Process leaks onto flange and bonnet fasteners may result in corrosion or environmental cracking.

This examination should include those flanges enclosed with flange or splash-and-spray guards.

5. FREQUENCY AND EXTENT OF INSPECTION

5.1 GENERAL :

The frequency and extent of inspection piping circuits depend on the forms of degradation that can affect the piping and consequence of a piping failure.

Inspection strategy based on likelihood and consequence of failure, is referred to as risk-based inspection. Piping classification scheme in Section given below is based on the consequence of a failure. The classification is used to establish frequency and extent of inspection. The owner/user may devise a more extensive classification scheme that more accurately assesses consequence for certain piping circuits. The consequence assessment would consider the potential for explosion, fire, toxicity, environmental impact and other potential effects associated with a failure.

After an effective assessment is conducted, the results can be used to establish a piping circuit inspection strategy and more specifically better define the following :

- The most appropriate inspection methods, scope, tools and techniques to be utilized based on the expected forms of degradation;

- The appropriate inspection frequency;

- The need for pressure testing after damage has been incurred or after repairs or modifications have been completed; and

- The prevention and mitigation steps to reduce the likelihood and consequence of a piping failure.

5.2 PIPING SERVICE CLASSES :

All process piping systems shall be categorized into different classes. Such a classification system allows extra inspection efforts to be focused on piping systems that may have the highest potential consequences if failure or loss of containment should occur. In general, the higher classified systems require more extensive inspection at shorter intervals in order to affirm their integrity for continued safe operation. Classifications should be based on potential safety and environmental effects should a leak occur.

5.2.1 CLASS 1 :

Services with the heist potential of resulting in an immediate emergency if a leak were to occur are in Class 1. Such an emergency may be safety or environmental in nature. Examples of Class1 piping include, but are not necessarily limited to, those containing the following :

- Flammable services that may auto-refrigerate and lead to brittle fracture.

- Pressurized services that may rapidly vaporize during release, creating vapors that may collect and form an explosive mixture, such as C2, C3 and C4 streams.

- Hydrogen sulfide (greater than 3 percent weight ) in a gaseous stream.

- Anhydrous hydrogen chloride.

- Hydrofluoric acid.

- Piping over or adjacent to water and piping over public through ways.

5.2.2 CLASS 2 :

Services not included in other classes are in Class 2. This classification includes the majority of unit process piping and selected off-site piping . Typical examples of these services include those containing the following :

- On-site hydrocarbons that will slowly vaporize during release.

- Hydrogen, fuel gas and natural gas

- On-site strong acids and caustics.

5.2.3 CLASS 3 :

Services that are flammable but do not significantly vaporize when they leak and are not located in high activity areas are in Class 3 . Services that dare potentially harmful to human tissue but are located in remote areas may be included din this class. Examples of Class 3 service are as follows :

- On site hydrocarbons that will not significantly vaporize during release.

- Distillate and product lines to and from storage and loading.

- Off-site acids and caustics.

5.3 INSPECTION INTERVALS :

The interval between piping inspections shall be established and maintained using the following criteria :

- Corrosion rate and remaining life calculations.

- Piping service classification.

- Applicable jurisdictional requirements

- Judgment of the inspector, the piping engineer, the piping engineer supervisor, or a corrosion specialist, based don operating conditions, previous inspection history, current inspection results, and conditions that may warrant supplemental inspections covered in 5.4.5 of code.

Thickness measurements should be scheduled based on the calculation of not more than half the remaining life determined from corrosion rates indicated or at the maximum intervals suggested in Table 6-1, whichever is shorter. Shorter intervals may be appropriate under certain circumstances. Prior to using Table 6-1, corrosion rates should be calculated in accordance with 7.13 of code.

The inspection interval must be reviewed and adjusted as necessary after each inspection or significant change in operating conditions. General corrosion, localized corrosion, pitting, environmental cracking, and other forms of deterioration must be considered when establishing the various inspection intervals.

5.4 EXTENT OF VISUAL EXTERNAL AND CUI INSPECTIONS :

External visual inspections, including inspections for corrosion under insulation (CUI), should be conducted at maximum intervals listed in Table 6-1 to evaluate items such as those in Appendix D. The external visual inspection on bare piping is to assess the condition of paint and coating systems, to check for external corrosion, and to check for other forms of deterioration. This external visual inspection for potential CUI is also to assess insulation condition and shall be conducted on all piping systems susceptible to CUI listed in 5.3.3.1 of code

Following the external visual inspection of susceptible systems, additional examination is required for the inspection of CUI. The extent and type of the additional CUI inspection are listed in Table 6-2 . Damaged insulation at higher elevations may result in CUI in lower areas remote from the damage. NDE inspection for CUI should also be conducted as listed in Table 6-2 at suspect locations of 5.3.3.1 (excluding c ) meeting the temperature criteria for 5.3.3.1 (e,f,h).

Radiographic examination or insulation removal and visual inspection is normally required for this inspection at damaged or suspect locations. Other NDE assessment methods may be used where applicable. If the inspection of the damaged or suspect areas has located significant CUI, additional area should be inspected and, where warranted, up to 100 percent of the circuit should be inspected.

The extent of the CUI program described in Table 6-2 should be considered as target levels for piping systems and locations with no CUI inspection experience. It is recognized that several factors may affect the likelihood of CUI to include :

- Local climatic conditions

- Insulation design.

- Coating quality.

- Service conditions.

Facilities with CUI inspection experience may increase or reduce the CUI inspection targets of Table 6-2. An exact accounting of the CUI inspection target is not required. The owner/user may confirm inspection targets with operational history or other documentation.

Piping systems that are known to have a remaining life of over 10 years or that are adequately protected against external corrosion need not be included for the NDE inspection recommended in Table 6-2. However, the condition of the insulating system or the outer jacketing, such as a cold-box shell, should be observed periodically by operating or other personnel. If deterioration is noted, it should be reported to the inspector. The following are examples of these systems :

- Piping systems insulated effectively to preclude the entrance of moisture.

- Jacketed cryogenic piping systems

- Piping systems installed in a cold box in which the atmosphere is purged with an inert gas.

- Piping systems in which the temperature being maintained is sufficiently low or sufficiently high to preclude the presence of water.

5.5 EXTENT OF THICKNESS MEASUREMENT INSPECTION :

To satisfy inspection interval requirements, each thickness measurement inspection should obtain thickness readings on a representative sampling of TMLs on each circuit . This representative sampling should include data for all the various types of components and orientations (horizontal and vertical) found in each circuit. This sampling also must include TMLs with the earliest renewal date as of the previous inspection. The more TMLs measured for each circuit, the more accurately the next inspection date will be projected. Therefore, scheduled inspection of circuits should obtain as many measurements as necessary.

The extent of inspection for injection points is covered in 5.3.1 of code.

-

- EXTENT OF SMALL-BORE, AUXILIARY PIPING, AND THREADED – CONNECTIONS INSPECTIONS :

5.6.1 SMALL BORE PIPING INSPECTION :

Small bore piping (SBP) that is primary process piping should be inspected in accordance with all the requirements of this document.

SBP that is secondary process piping has different minimum requirements depending upon service classification. Class1 secondary SBP shall be inspected to the same requirements as primary process piping. Inspection of Class2 and Class 3 secondary SBP is optional. SBP deadlegs (such das level bridles) in Class 2 and Class 3 systems should be inspected where corrosion has been experienced or is anticipated.

5.6.2 AUXILIARY PIPING DDDDINSPECTION :

Inspection of secondary, auxiliary SBP associated with instruments and machinery is optional. Criteria to consider in determining whether auxiliary SBP will need some form of inspection include the following :

- Classification.

- Potential for environmental or fatigue cracking.

- Potential for corrosion based on experience with adjacent primary

system.

- Potential for CUI.

5.6.3 THREADED-CONNECTIIONS INSPECTION :

Inspection of threaded connections will be according to the requirements listed above for small-bore and auxiliary piping. When selecting TMLs on threaded connection, include only those that can be radio-graphed during scheduled inspection.

Threaded connections associated with machinery and subject to fatigue damage should be periodically assessed and considered for possible renewal with a thicker wall or upgrading to welded components. The schedule for such renewal will depend on several issues, including the following :

- Classification piping

- Magnitude and frequency of vibration.

- Amount of unsupported weight.

- Current piping wall thickness.

- Whether or not the system can be maintained on stream.

- Corrosion rate.

- Intermittent service.

TABLE 6-1—-RECOMMENDED MAXIMUM INSPECTION INTERVALS

|

Types of Circuit |

Thickness Measurements |

Visual External |

|

Class 1 |

5 years |

5 years |

|

Class 2 |

10 years |

5 years |

|

Class 3 |

10 years |

10 years |

|

Injection points |

3 years |

By Class |

|

Soil-to-air interfaces |

—- |

By Class |

Note : Thickness measurements apply to systems for which TMLs have been

established in accordance with 5.5

TABLE D6-2 — RECOMMENDED EXTENT OF CUI INSPECTION

FOLLOWING VISUAL INSPECTION

|

Approximate Amount of Followup Examination with NDE or Insulation Removal at Areas with Damaged Insulation |

Approximate Amount of CUI Inspection by NDE at Suspect Areas ( 5.3.3.2 ) on Piping Systems within Susceptible Temperature Ranges ( 5.3.3.2 e.f.h ) |

|

|

Pipe Class |

||

|

1 |

75% |

50% |

|

2 |

50% |

33% |

|

3 |

25% |

10% |

6. INSPECTION DATA EVALUATION

6.1 CORROSION RATE DETERMINATION :

-

-

- REMAINING LIFE CALCULATIONS :

-

The dreaming life of the piping system shall be calculated from the following formula :

t actual – t minimum

Remaining life (years) = —————————–

Corrosion rate

[inches (mm) per year]

where :

t actual = the actual minimum thickness, in inches (mm),determined at the

time of inspection as specified 5.6

t minimum = the minimum required thickness, in inches (mm) for the limiting

section or zone.

The long term (L.T.) corrosion rate of piping circuits shall be calculated from the following formula :

Corrosion rate (L.T.) = t initial – t last

———————————

time (years) between last

and initial inspections

The short term (S.T.) corrosion rate of piping circuits shall be calculated from the following formula :

Corrosion rate (S.T.) = t previous – t last

—————————

time (years) between last

and previous inspections

Long term and short term corrosion rates should be compared to see which results in the shortest remaining life.

6.1.2 EXISTING PIPING SYSTEMS :

Corrosion rates shall be calculated on either a short term or a long term basis. For the short term calculation, readings from the two most recent inspections shall be used. For the long term calculation, wall thicknesses from the most recent and initial (or nominal) inspections shall be used. In most cases, the higher of these two rates should be used to estimate remaining life and so set the next inspection interval.

If calculations indicate that an inaccurate rate of corrosion has been assumed, the rate to be used for the next period shall be adjusted to agree with the actual rate found.

6.2 MAXIMUM ALLOWABLE DWORKING PRESSURE DETERMINATION :

The maximum allowable working pressure (MAWP) for the continued use of piping systems shall be established using the applicable code. Computations may be made for known materials if all the following essential details are known to comply with the principles of the applicable code :

- Upper and/or lower temperature limits for specific materials.

- Quality of materials and workmanship.

- Inspection requirements.

- Reinforcement of openings.

- Any cyclical service requirements.

For unknown materials, computations may be made assuming the lowest grade material and joint efficiency in the applicable code. When the MAWP is recalculated, the wall thickness used in these computations shall be the actual thickness as determined by inspection (see definition) minus twice the estimated corrosion loss before the date of the next inspection. Allowance shall be made for the other loadings in accordance with the applicable code. The applicable code allowances for pressure and temperature variations from MAWP are permitted provided all of the associated code criteria are satisfied.

6.3 MINIMUM REQUIRED THICKNESS DETERMINATION :

The minimum required pipe wall thickness, or retirement thickness, shall be based on pressure, mechanical, and structural considerations using the appropriate design formulas and code allowable stress. Consideration of both general and localized corrosion shall be included. For services with high potential consequences if failure were to occur, the piping engineer should consider increasing the required minimum thickness above the calculated minimum thickness to provide for unanticipated or unknown loadings, undiscovered metal loss, or resistance to normal abuse.

6.4 REPORTING AND RECORDS FOR PIPING SYSTEM INSPECTION

Any significant increase in corrosion rates shall be reported to the owner/user for appropriate action.

The owner/user shall maintain appropriate permanent and progressive records of each piping system covered by API 570. These records shall contain pertinent data such as piping system service; classification; identification numbers; inspection intervals; and documents necessary to record the name of the individual performing the testing, the date, the types of testing, the results of thickness measurements and other tests, inspections, repairs (temporary and permanent), alterations, or rerating. Design information and piping drawings may be included. Information on maintenance activities and events affecting piping system integrity also should be included. The date and results of required external inspections shall be recorded. (see API RP 574 for guidance on piping inspection records).

The use of a computer based system for storing, calculating, and analyzing data should be considered in view of the volume of data that will be generated as part of a piping test-point program. Computer programs are particularly useful for the following :

- Storing the actual thickness reading.

- Calculating short and long term corrosion rates, retirement dates, MAWP, and reinspection intervals on a test point by test point basis.

- Highlighting areas of high corrosion rates, circuits over-due for inspection, close to retirement thickness, and other information.

7. REPAIRS, ALTERATIONS, RERATING

7.1 REPAIRS AND ALTERATIONS :

The principles of ASME B31.3 or the code to which the piping system was built shall be followed.

7.1.1 AUTHORIZATION :

All repair and alteration work must be done by a repair organization as defined in Section 3 and must be authorized by the inspector prior to its commencement. Authorization for alteration work to a piping system may not be given without prior consultation with, and approval by, the piping engineer. The inspector will designate any inspection hold points required during the repair or alteration sequence. The inspector may give prior general authorization for limited or routine repairs and procedures, provided the inspector is satisfied with the competency of the repair organization.

7.1.2 APPROVAL :

All proposed methods of design, execution, materials, welding procedures, examination, and testing must be approved by the inspector or by the piping engineer, as appropriate. Owner/user approval of on stream welding is required.

Welding repairs of cracks that occurred in service should not be attempted without prior consultation with the piping engineer in order to identify and correct the cause of the cracking. Examples are cracks suspected of being caused by vibration, thermal cycling, thermal expansion problems, and environmental cracking.

The inspector shall approve all repair and alteration work at designated hold points and after the repairs and alterations have been satisfactorily completed in accordance with the requirements of API 570

7.1.3 WELDING REPAIRS (DDINCLUDING ON0STREAM) :

7.1.3.1 TEMPORARY REPAIRS :

For temporary repairs, including on steam, a full encirclement welded split sleeve or box type enclosure designed by the piping engineer may be applied over the damaged or corroded area. Longitudinal cracks shall not be repaired in this manner unless the piping engineer has determined that cracks would not be expected to propagate from under the sleeve. In some cases, the piping engineer will need to consult with a fracture analyst.

If the repair area is localized (for example, pitting or pinholes) and the specified minimum yield strength (SMYS) of the pipe is not more than 40,000 psig (275,800 kPa), a temporary repair may be made by fillet welding a properly designed split coupling or plate patch over the pitted area (See 7.2.3 for design considerations and Appendix C for an example ) The material for the repair shall match the base metal unless approved by the piping engineer.

For minor leaks, properly designed enclosures may be welded over the leak while the piping system is in service, provided the inspector is satisfied that adequate thickness remains in the vicinity of the weld and the piping component can withstand welding without the likelihood of further material damage, such as form caustic service.

Temporary repairs should be removed and replaced with a suitable permanent repair at the next available maintenance opportunity. Temporary repairs may remain in place for a longer period of time only if approved and documented by the piping engineer.

7.1.3.2 PERMANENT REPAIRS :

Repairs to defects found in piping components may be made by preparing a welding groove that completely removes the defect and then filling the groove with weld metal deposited din accordance with 7.2

Corroded areas may be restored with weld metal deposited din accordance with 7.2 Surface irregularities and contamination shall be removed before welding. Appropriate NDE methods shall be applied after completion of the weld.

If it is feasible to take the piping system out of service, the defective area may be removed by cutting out a cylindrical section and replacing it with a piping component that meets the applicable code.

Insert patches (flush patches) may be used to repair damaged or corroded areas if the following requirements are met :

- Full penetration groove welds are provided.

- For Class 1 and Class 2 piping systems, the welds shall be

100 percent radio-graphed or ultrasonically tested using NDE procedures that are approved by the inspector.

- Patches may be any shape but shall have rounded corners

(1 inch (25mm) minimum radius)

7.1.4 NON-WELDING REPAIRS (ON STREAM) :

Temporary repairs of locally thinned sections or circumferential linear defects may be made on stream by installing a properly designed and fabricated bolted leak clamp. The design shall include control of axial thrust loads if the piping component being clamped is (or may become) insufficient to control pressure thrust. The effect of clamping (crushing) forces on the component also shall be considered.

During turnarounds or other appropriate opportunities, temporary leak sealing and leak dissipating devices, including valves, shall be removed and appropriate actions taken to t\restore the original integrity of the piping system. The inspector and/or dipping engineer shall be involved in determining repair methods and procedures.

Procedures that include leak sealing fluids (pumping) for process piping should be reviewed for acceptance by the inspector or piping engineer. The review should take into consideration the compatibility of the sealant with the leaking material; the pumping pressure on the clamp (especially when re[pumping); the risk of sealant affecting downstream flow meters, relief valves, or machinery, the risk of subsequent leakage at bolt threads causing corrosion or stress corrosion cracking of bolts; and the number of times the seal area is re-pumped.

7.2 WELDING AND HOT TAPPING :

All repair and alteration welding shall be done in accordance with the principles of ASME B 31.3 or the code to which the piping system was built.

Any welding conducted on piping components in operation must be done in accordance with API Publ 2201. The inspector shall use as a minimum the ‘ Suggested Hot Tap Checklist” contained in API Publication 2201 for hot tapping performed on piping components.

7.2.1 PROCEDURES, QUALIFICATIONS, AND RECORDS :

The repair organization shall use welders and welding procedures qualified in accordance with ASME B31.3 or the code to which the piping was built.

The repair organization shall maintain records of welding procedures and welder performance qualifications. These records shall be available to the inspector prior to the start of welding.

7.2.2 PERHEATING AND POSTWELD HEAT TREATMENT :

7.2.2.1 PREHEATING :

Preheat temperature used in masking welding repairs shall be in accordance with the applicable code and qualified welding procedure. Exceptions for temporary repairs must be approved by the piping engineer.

Preheating to not less that 300oF (150oC) may be considered as an alternative to postweld heat treatment (PWHT) for alterations or repairs of piping systems initially postweld heat heated as a code requirement (see note). This applies to piping constructed of the P-1 steels listed in ASME B31.3. P-3 steels , with the exception of Mn-Mo steels, also may receive the 300oF(150oC) minimum preheat alternative when the piping system operating temperature is high enough to provide reasonable toughness and when there is no identifiable hazard associated with pressure testing , shutdown, and startup. The inspector should determine that the m9inimum preheat temperature is measured and maintained. After welding, the joint should immediately be covered with insulation to slow the cooling rate.

NOTE : Preheating may not be considered as an alternative to environmental cracking prevention.

Piping systems constructed of other steel initially requiring PWHT normally are postweld heat treated if alterations or repairs involving pressure retaining welding are performed. The use of the preheat alternative requires consultation with the piping engineer who should consider the potential for environmental cracking and whether the welding procedure will provide adequate toughness. Examples of situations where this alternative could be considered include seal welds, weld metal buildup of thin area, and welding support clips.

7.2.2.2 POSTWELD HEAT TREATMENT :

PWHT of piping system repairs or alterations should be made using the applicable requirements of ASME B31.3 or the code to which the piping was built. See 7.2.2.1 for an alternative preheat procedure for some PWHT requirements. Exceptions for temporary repair must be approved by the piping engineer.

Local PWHT may be substituted for 360- degree banding on local repairs on all materials, provided the following precautions and requirements are applied.

- The application is reviewed, and a procedure is developed

by the piping engineer.

- In evaluating the suitability of a procedure, consideration

shall be given to applicable factors, such as base metal thickness, thermal gradients, material properties, changes resulting from PWHT, the need for full penetration welds, and surface and volumetric examinations after PWHT. Additionally, the overall and local strains and distortions resulting from the heating of a local restrained area of the piping wall shall be considered in developing and evaluating PWHT procedures.

- A preheat of 300oF (150oC), or higher as specified by

specific welding procedures, is maintained while welding.

- The required PWHT temperature shall be maintained for a

distance of not less than two times the base metal thickness measured form the weld. The PWHT temperature shall be monitored by a suitable number of thermocouples (a minimum of two) based on the size and shape of the area being heat treated.

- Controlled heat also shall be applied to any branch

connection or other attachment within the PWHT area.

- The PWHT is performed for code compliance and not for

environmental cracking resistance.

7.2.3 DESIGN :

Butt joints shall be full penetration groove welds.

Piping components shall be replaced when repair is likely to be inadequate. New connections and replacement s shall be designed and fabricated according to the principles of the applicable code. The design of temporary enclosures and repairs shall be approved by the piping engineer.

New connections may be installed on piping systems provided the design, location, and method of attachment conform to the principles of the applicable code.

Fillet-welded patches require special design considerations, especially relating to weld-joint efficiency and crevice corrosion. Fillet-welded patches shall be designed by the piping engineer. A patch may be applied to the external surfaces of piping, provided it is in accordance with 7.1.3 and meets either of the following requirements. :

- The proposed patch provides design strength equivalent to a reinforced opening designed according to the applicable code.

- The proposed patch is designed to absorb the membrane strain of the part in a manner that is in accordance with the principles of the applicable code, if the following criteria are met :

- The allowable membrane stress is not exceeded in the piping part

or the patch.

-

- The strain in the patch does not result in fillet weld stresses exceeding allowable stresses for such welds.

- An overlay patch shall have rounded corners (se Appendix C)

7.2.4 MATERIALS :

The materials used in making repairs or alterations shall be of known weldable quality, shall conform to the applicable code, and shall be compatible with the original materials. For material verification requirements see 4.8

7.2.5 NON-DESTRUCTIVE EXAMINATION :

Acceptance of a welded repair or alteration shall include NDE in accordance with the applicable code and the owner/user’s specification, unless otherwise specified in API 570

7.2.6 PRESSURE TESTING :

After welding is completed, pressure test in accordance with 4.7 shall be performed if practical and deemed necessary by the inspector. Pressure tests are normally required after alterations and major repairs. When a pressure test is not necessary or practical, NDE shall be utilized in lieu of a pressure test. Substituting special procedures for a pressure test after an alteration or repair may b e done only after consultation with the inspector and the piping engineer.

When it is not practical to perform a pressure test of a final closure weld that joins a new or replacement section of piping to an existing system, all of the following requirements shall be satisfied :

- The new or replacement piping is pressure tested.

- The closure weld is a full penetration butt-weld between a weld neck flange and standard piping component or straight sections of pipe of equal diameter and thickness, axially aligned ( not miter cut ), and of equivalent materials. Acceptable alternatives are

- slip-on flanges for design cases upto Class 150 and 500oF,

(260oC) and

-

- socket welded flanges or socket welded unions for sizes NPS 2 or

less and design cases upto Class 150 and 500oF (260oC). A spacer designed for socket welding or some other means shall be used to establish a minimum 1/16 inch (1.6 mm ) gap. Socket welds shall be per ASME B31.3 and shall be a minimum of two passes.

- Any final closure butt-weld shall be of 100 percent radiographic quality;

OR angle beam ultrasonics flaw detection may be used, provided the appropriate acceptance criteria have been established.

- MT or PT shall be performed on the root pass and the completed weld for

butt-welds and on the completed weld for fillet welds.

7.3 RERATING

Rerating piping systems by changing the temperature rating or the MAWP may be done only after all of the following requirements have been met :

- Calculations are performed by the piping engineer or the inspector.

- All ratings shall be established in accordance with the requirements of the code to which the piping system was built or by computation using the appropriate methods in the latest edition of the applicable code.

- Current inspection records verify that the piping system is satisfactory for the proposed service conditions and that the appropriate corrosion allowance is provided.

d. Rerated piping systems shall be leak tested in accordance with the code to which the piping system was built or the latest edition of the applicable code for the new service conditions, unless documented records indicate a previous leak test was performed at greater than or equal to the test pressure for the new condition. An increase in the rating temperature that does not affect allowable tenside stress does not require a leak test.

- The piping system is checked to affirm that the required pressure relieving devices are present, are set at the appropriate pressure, and have the appropriate capacity at set pressure.

f. The piping system rerating is acceptable to the inspector or piping engineer.

g. All piping components in the system (such as valves, flanges, bolts, gaskets, packing, and expansion joints) are adequate for the new combination of pressure and temperature.

h. Piping flexibility is adequate for design temperature changes.

i. Appropriate engineering records are updated.

j. A decrease in minimum operating temperature is justified by impact test results, if required by the applicable code.

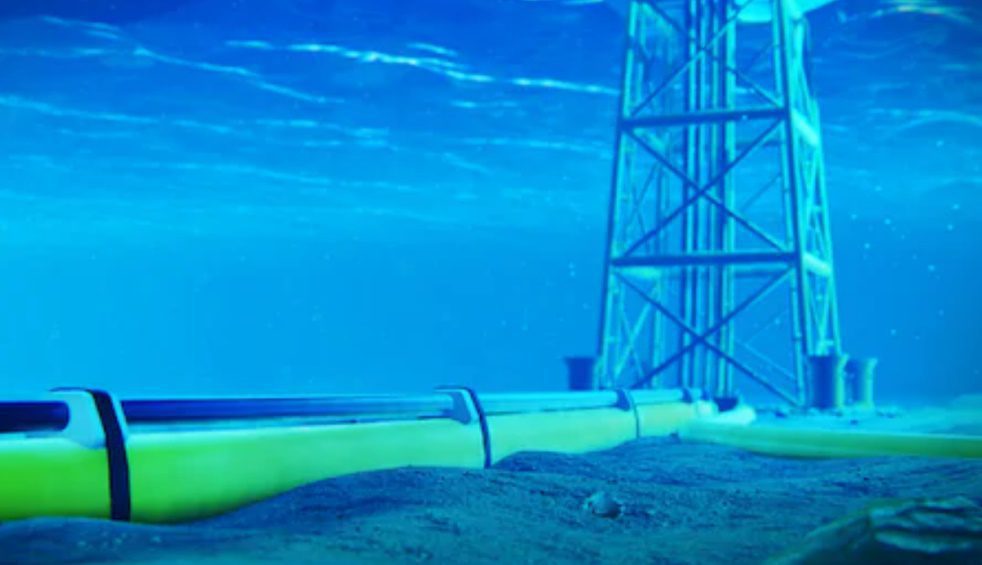

8. INSPECTION OF BURIED PIPING

Inspection of buried process piping is different from other process piping inspection because significant external deterioration can be caused by corrosive soil conditions. Since the inspection is hindered by the inaccessibility of the affected areas of the piping, the inspection of buried piping is treated in a separate section of API 570.

8.1 TYPES AND METHODS OF INSPECTION

-

-

- Above Grade Visual Surveillance :

-

Indications of leaks in buried piping may include a change in the surface contour of the ground, discoloration of the soil, softening of paving asphalt, pool formation, bubbling water puddles, or noticeable odor. Surveying the route of buried piping is one method of identifying problem areas.

-

-

- Close Interval Potential Survey :

-

The close interval potential survey performed at ground level over the buried pipe can be used to locate active corrosion points on the pipe’s surface.

Corrosion cells can form on both bare and coated pipe where the bare steel contacts the soil. Since the potential at the area of corrosion will be measurably different from an adjacent area on the pipe, the location of the corrosion activity can be determined by this survey technique.

-

-