Navigating the World of NDT Certification and Training: A Comprehensive Guide

Non-Destructive Testing (NDT) is a multifaceted field that requires a blend of theoretical knowledge and practical skills. Professionals in this industry must undergo rigorous training and certification to ensure they are equipped to perform their duties with precision and integrity. This comprehensive guide delves into the various aspects of NDT certification and training, highlighting the importance of continuous education and the pathways to becoming an NDT expert.

Understanding NDT Certification Levels

NDT certification is a testament to a professional’s competence in performing specific tasks within the field. The certification process is categorized into three main levels:

- Level I: This entry-level certification is designed for individuals beginning their journey in NDT. Level I professionals are trained to perform specific calibrations and evaluations under direct supervision. They are introduced to basic concepts and methodologies, laying the foundation for further growth.

- Level II: At this intermediate level, professionals are expected to have a deeper understanding of NDT methods. They are trained to set up and calibrate equipment, interpret and evaluate results, and prepare written instructions. Level II certification opens doors to more responsibilities and opportunities within the industry.

- Level III: This advanced level emphasizes the development of new techniques, interpretation of codes, and supervisory responsibilities. Level III professionals are considered experts in their field, often taking on leadership roles and contributing to the advancement of NDT practices.

Importance of NDT Training

Training plays a pivotal role in shaping an NDT professional’s career. Here’s why NDT training is indispensable:

- Skill Enhancement: Through hands-on training, professionals can master various NDT methods, enhancing their ability to detect and evaluate defects.

- Safety Compliance: Proper training ensures that professionals understand and adhere to safety protocols, safeguarding both human lives and equipment.

- Quality Assurance: Training ensures that inspections are conducted with the highest standards of quality, minimizing errors and ensuring reliability.

NDT Training Programs

Training programs in NDT are tailored to different methods and industry needs. These programs equip professionals with the necessary skills and knowledge to excel in their chosen field. Some popular training programs include:

- Ultrasonic Testing (UT) Training: This program focuses on using high-frequency sound waves to detect internal defects. It covers principles, equipment calibration, and defect characterization.

- Radiographic Testing (RT) Training: Professionals are trained to use X-rays or gamma rays to create images of internal structures. This includes understanding radiation safety, image interpretation, and evaluation techniques.

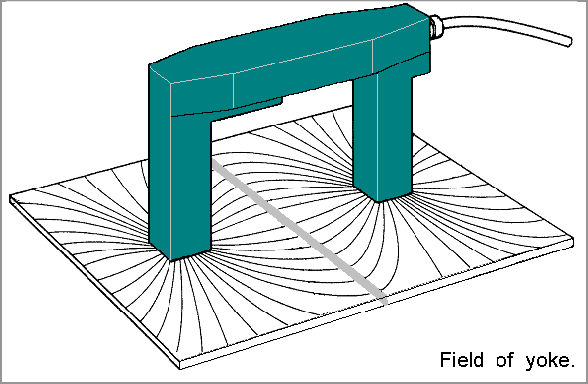

- Magnetic Particle Testing (MT) Training: This training involves using magnetic fields to detect surface and subsurface defects in ferromagnetic materials. It includes magnetization techniques, equipment handling, and defect identification.

- Visual Inspection (VT) Training: This fundamental training emphasizes visual inspection techniques to identify visible defects. It covers lighting, inspection procedures, and reporting methodologies.

- Liquid Penetrant Testing (PT) Training: This program teaches the application of liquid penetrants to detect surface-breaking defects. It includes penetrant selection, application methods, and result interpretation.

- Eddy Current Testing (ET) Training: This training focuses on using electromagnetic induction to detect defects in conductive materials. It covers principles, equipment handling, and defect characterization.

- Acoustic Emission (AE) Training: Professionals learn to analyze the acoustic signals emitted from materials under stress. It includes sensor selection, signal analysis, and application in structural health monitoring.

- Thermography (IRT) Training: This program teaches the use of infrared thermography to detect variations in temperature. It includes understanding thermal patterns, equipment handling, and application in various industries.

- Leak Testing (LT) Training: This training covers methods to detect and locate leaks in systems and components. It includes understanding leak rates, testing techniques, and application in quality control.

- Guided Wave Testing (GWT) Training: This advanced program focuses on using guided waves for long-range inspection. It includes wave propagation, equipment handling, and application in pipeline inspection.

- Time of Flight Diffraction (ToFD) Training: Professionals learn to use ultrasonic waves to measure the time of flight of a diffracted wave. It includes principles, equipment calibration, and application in weld inspection.

- Phased Array Ultrasonics (PAUT) Training: This specialized training program focuses on the use of phased array technology in ultrasonic testing. It covers principles of beam formation, equipment handling, data interpretation, and application in complex geometries and materials.

These diverse training programs cater to various aspects of NDT, offering professionals the opportunity to specialize in different techniques and applications. By engaging in these programs, NDT professionals can enhance their skills, adhere to industry standards, and contribute to the overall quality and safety of products and structures.

NDT Training Providers

- ASNT (American Society for Nondestructive Testing)

- Website: www.asnt.org

- TWI (The Welding Institute)

- Website: www.twitraining.com

- Hellier NDT Training

- Website: www.hellierndt.com

- Lavender International NDT Consultancy Services

- Website: www.lavender-ndt.com

- MISTRAS Group

- Website: www.mistrasgroup.com

- NDT Classroom

- Website: www.ndtclassroom.com

- Zetec NDT Training

- Website: www.zetec.com

- Applus+ RTD

- Website: www.applusrtd.com

- Olympus IMS

- Website: www.olympus-ims.com

- SGS NDT Training Center

- Website: www.sgs.com

- Global NDE Guru

- Website: www.globalndeguru.com

- Quality Testing Services, Inc.

- Website: www.qualitytesting.com

- TÜV Rheinland

- Website: www.tuv.com

- Bureau Veritas

- Website: www.bureauveritas.com

- AINDT (Australian Institute for Non-Destructive Testing)

- Website: www.aindt.com.au

These providers offer a wide range of NDT training programs and certifications, catering to various industry needs and professional development goals. It’s recommended to explore their websites to find the courses that best align with your specific requirements and interests.

Continuous Education in NDT

The dynamic nature of the NDT field necessitates continuous education. Here’s how ongoing learning benefits professionals:

- Stay Updated: Regular participation in workshops, seminars, and courses keeps professionals abreast of the latest technological advancements and industry trends.

- Enhance Career Growth: Continuous learning fosters professional development, opening doors to new opportunities and career advancements.

- Maintain Certification: Ongoing education is often required to keep certifications valid, ensuring that professionals continue to meet industry standards.

NDT Standards

NDT standards are essential in ensuring the quality and consistency of non-destructive testing practices. Below is a list of some key NDT standards and the organizations responsible for developing and maintaining them.

- ASTM International (American Society for Testing and Materials)

- Standards: ASTM E1316, ASTM E1417, ASTM E1444, etc.

- Website: www.astm.org

- ASNT (American Society for Nondestructive Testing)

- Standards: SNT-TC-1A, CP-189, etc.

- Website: www.asnt.org

- ISO (International Organization for Standardization)

- Standards: ISO 9712, ISO 17635, ISO 17637, etc.

- Website: www.iso.org

- EN (European Standards)

- Standards: EN 473, EN 4179, EN 10228, etc.

- Website: www.cen.eu

- AWS (American Welding Society)

- Standards: AWS D1.1, AWS B1.10, etc.

- Website: www.aws.org

- API (American Petroleum Institute)

- Standards: API RP 2X, API 1104, etc.

- Website: www.api.org

- ANSI (American National Standards Institute)

- Standards related to NDT in various industries.

- Website: www.ansi.org

- BSI (British Standards Institution)

- Standards: BS EN ISO 9712, BS EN 583, etc.

- Website: www.bsigroup.com

- JIS (Japanese Industrial Standards)

- Standards related to NDT in Japan.

- Website: www.jisc.go.jp

- SAE International (Society of Automotive Engineers)

- Standards related to NDT in the automotive industry.

- Website: www.sae.org

- A4A (Airlines for America)

- Standards: NAS 410 (Aerospace Industries Standard)

- Website: www.airlines.org

- NACE International (National Association of Corrosion Engineers)

- Standards related to NDT for corrosion control.

- Website: www.nace.org

- IEEE (Institute of Electrical and Electronics Engineers)

- Standards related to NDT in electrical and electronics engineering.

- Website: www.ieee.org

These organizations play a vital role in defining and maintaining the standards that govern NDT practices across various industries. By adhering to these standards, professionals ensure that their work meets the highest levels of quality, safety, and integrity. It’s advisable to explore the websites of these organizations for detailed information on specific standards and their applications.

NDT Inspect Training Group: A Valuable Resource for Professionals

For those actively engaged in the field of Non-Destructive Testing (NDT) and looking for comprehensive training resources, NDT Inspect offers an exclusive opportunity. Active members of NDT Inspect can gain access to the Training Group, a specialized section of the platform dedicated to enhancing professional development.

What’s Available in the Training Group?

The Training Group on NDT Inspect is a treasure trove of valuable materials for NDT professionals. Here’s what members can find:

- Vast Collection of Documents: From technical manuals to industry guidelines, the Training Group hosts an extensive library of documents catering to various NDT methods and applications.

- Training Books: Whether you’re a beginner or an experienced professional, the collection of training books available in the Training Group covers a wide range of topics, offering insights, techniques, and best practices in NDT.

- Collaborative Learning Environment: The Training Group fosters a community of like-minded professionals, providing a platform for collaboration, discussion, and knowledge sharing.

- Continuous Learning Opportunities: With regular updates and additions, the Training Group ensures that members have access to the latest information, tools, and resources to stay ahead in the ever-evolving field of NDT.

How to Access the Training Group?

Access to the Training Group is exclusive to active members of NDT Inspect. By becoming a member and actively participating in the community, professionals can unlock this valuable resource, enhancing their skills, knowledge, and career growth.

Visit the NDT Inspect Training Page to learn more about the Training Group and discover how you can become a part of this vibrant and resourceful community.

NDT Inspect Groups and Forum: Your Go-To Platforms for NDT Insights

In the dynamic and complex world of Non-Destructive Testing (NDT), having access to a community of experts and a wealth of information is invaluable. NDT Inspect offers two distinct platforms that serve as essential resources for professionals seeking answers, collaboration, and continuous learning in the field of NDT.

NDT Inspect Groups

The NDT Inspect Groups provide a collaborative space where professionals can connect, share knowledge, and engage in meaningful discussions. Whether you’re looking for specific answers, seeking guidance on best practices, or wanting to network with fellow NDT experts, the groups offer a vibrant community to support your needs.

- Diverse Topics: From ultrasonic testing to radiography, the groups cover a wide range of NDT methods and applications.

- Expert Insights: Engage with seasoned professionals and industry leaders who share their expertise and experiences.

- Collaborative Learning: Participate in discussions, ask questions, and contribute to the collective knowledge of the NDT community.

NDT Forum – Inspection Forum

The NDT Forum, also known as the Inspection Forum, is a dedicated platform where professionals can search for answers, post queries, and interact with experts in the field of NDT. It’s a hub for knowledge exchange, offering:

- In-Depth Discussions: Explore threads on various NDT topics, methodologies, and industry trends.

- Expert Assistance: Post your questions and receive answers from experienced professionals and industry peers.

- Knowledge Archive: Search the forum’s extensive archive to find answers to previously asked questions, providing a rich resource for learning and problem-solving.

NDT Inspect’s Groups and Forum are more than just online platforms; they are thriving communities that foster collaboration, knowledge sharing, and professional growth. By actively participating in these spaces, NDT professionals can find answers, gain insights, and contribute to the broader NDT community.

Visit the NDT Inspect Groups and NDT Forum – Inspection Forum to explore these valuable resources and become an active part of the NDT Inspect community.

Conclusion

The path to becoming an NDT professional is a continuous journey of learning, growth, and self-improvement. From the initial steps of understanding certification levels to engaging in specialized training programs and embracing the culture of continuous education, every stage is vital in shaping a competent and skilled NDT professional.

This comprehensive guide serves as a roadmap for current and aspiring NDT professionals, encouraging them to invest in their education and training. By fostering a culture of continuous learning and adhering to the highest standards of quality and integrity, we can ensure a thriving and competent NDT community that continues to push the boundaries of innovation and excellence.

Responses