NON-DESTRUCTIVE TESTING OF STEEL WIRE ROPES AND THEIR DISCARD CRITERIA

The 8th International Conference of the Slovenian Society for Non-Destructive Testing

»Application of Contemporary Non-Destructive Testing in Engineering« September 1-3, 2005, Portorož, Slovenia, pp. 229-235

NON-DESTRUCTIVE TESTING OF STEEL WIRE ROPES AND THEIR DISCARD CRITERIA

S.K. Kashyap, G. Laxminarayna, S. Tewari, A. Sinha

Central Mining Research Institute, Barwa Road, Dhanbad-826001, Jharkhand, India,

E-mail: sudhirnutan@yahoo.com

ABSTRACT

Steel wire ropes are extensively used for haulage purposes in mine winders and aerial ropeway carrying/haulage/track ropes for transportation of passengers and play a vital role in these installation. Structural integrity of these wire ropes is to be monitored to safe guard human lives. The regular periodic non-destructive investigation right from the date of installation after allowing a constructional stretch will not only enable the user to achieve optimum safe utilization ,but also to alarm when untoward deterioration is caused due to different parameters.

Different countries adopt different rope discard criteria to caution the user by conducting a non-destructive investigation to detect the rope deterioration which otherwise would have been unnoticed by mere visual inspection to assess the rope condition while they are in service.

The authors would like to throw some light on this technique and discuss the criteria for rope discard by developed countries adopting this technique as mandatory.

Keywords: Non-destructive testing, Steel wire ropes, Discard Criteria

Introduction

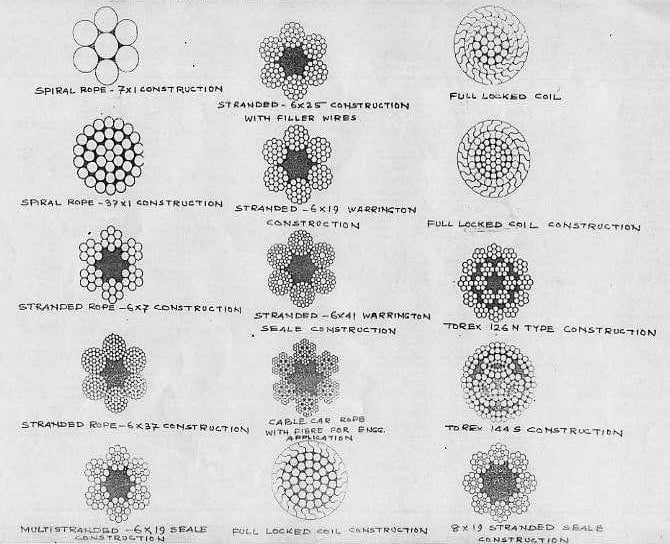

Steel wire ropes used for hauling men and material from underground mines as well as hauling truck purposes in aerial rope way passenger cable car installation are basically of two different construction namely stranded construction and locked coil construction.

Table 1 shows the steel wire ropes of different types and constructions used in mine winders/aerial ropeways and allied applications. Deterioration caused due to service condition in a rope are classified in two categories namely localized flaws (LF) and distributed flaws or flaws due to loss in metallic area (LMA). Localized flaws due to broken wires nicking etc.

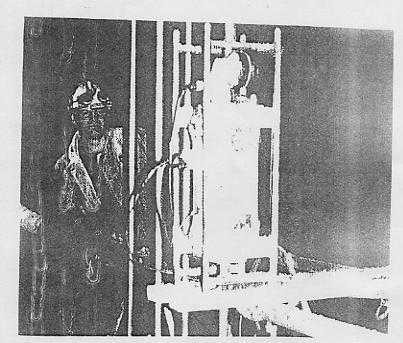

whereas distributed flaws are mainly due to corrosion, wear, abrasion, pitting of wires etc. The methodology of non-destructive testing of steel wire ropes and their discard criteria adopted by different countries for mine winder ropes as well as on haulage and track ropes for aerial ropeway passenger cable car installation are briefed in this paper. Non-destructive investigation on a shaft winder rope has been shown in Fig.1.

Table 1: Steel wire ropes of different types and construction used.

Fig. 1: Non destructive investigation on a shaft winder rope.

Methodology

There are different types of instruments for evaluation of rope condition namely

- electromagnetic instruments

- direct current and permanent magnet method instruments and

- Magnetic flux leakage instruments.

- Electromagnetic instruments

It works on the transformer principle with primary and secondary coil wound around a rope where rope acts as a transformer core. The primary coil (which is the exciter) is energized with a low frequency A.C in the range of 10 to 30 Hz and the secondary coil which is search coil measures the magnetic characteristics of the rope i.e. the wire rope will cause a voltage change (in amplitude and phase ) in the secondary coil. This type of instruments operates at relatively low magnetic field strength and hence designed to detect changes in metallic cross sectional area and it is essential to demagnetize the rope completely before examination.

- Direct current and permanent magnet method instruments

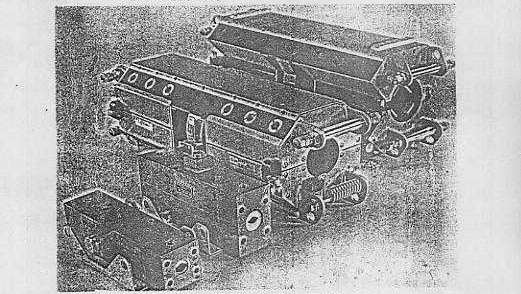

This type of instrument supplies a constant flux which magnetizes a length of rope which passes through a magnetic head. Fig. 2 and Fig. 3 show the different types of magnetic head. The total axial magnetic flux in the rope can be measured either by Hall Effect sensor, an encircling coil or by any other appropriate device that can measure absolute magnetic field or variation in a steady magnetic field. This signal obtained through the sensor or encircling coil is electronically processed and the output voltage is proportional to the volume of steel or the change in metallic cross sectional area within the region of influence of the magnetizing current. This type of instruments measures change in metallic area.

Fig 2: Magnetic heads for different sizes of wire rope.

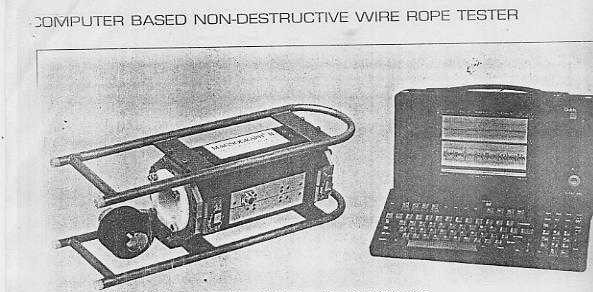

Fig. 3: Magnetic head and portable computer

- Magnetic flux leakage instruments

A direct current or a permanent magnet instruments is used to supply a constant flux that magnetizes a length of rope which passes through the magnetic head. The magnetic flux leakage

created by a discontinuity in the rope such as broken wire can be measured with a different sensor such as Hall Effect, sensor (inductive) coil or by any appropriate device. This signal from the sensor is electronically processed and recorded. The electronic integrated circuit integrates the sensing coil signals directly to determine the magnetic flux in the rope and subsequently the rope cross sectional area.

Therefore LMA may be estimated quantitatively by measuring the total magnetic flux directly in the rope with an accuracy to detect as small as 0.05 % loss of cross sectional area. While all presently available instrument can perform either LF inspection or LMA inspection, whereas modern instruments are of the dual function type and can perform combined LF/LMA inspection.

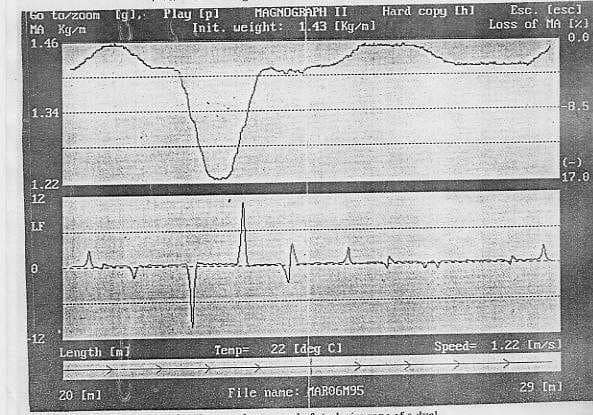

Wire rope damage recorder with Hall Effect sensor (dual function type) has been shown in Fig. 4. Oscillation chart record of steel wire rope of a dual function type equipment revealing loss in mass in Kg/meter (0-20 Kg) of a steel wire in service along with loss in metallic area (LMA) and Localized Flaw (LF) have been illustrated in Fig. 5.

Fig. 4: Wire rope damage recorder with hall effect sensor (dual function equipment)

Fig. 5: Oscillogram chart record of steel wire rope of a dual function side equipment – revealing loss in mass in Kg/metre (0-20 Kg) of a steel wire in service along with loss in metallic area (LMA) and localized flaws (LF)

Wire rope users now recognize that EM inspection is powerful preventive maintenance tool. Those who test wire ropes should follow the stipulated guidelines to assure reliable results and

the users of the rope should be familiar with the standards, understand the NDT procedure followed and the test results provided by the testing agency.

The phenomena of rope evaluation by conducting Non-destructive tests by assessing the localized flaws viz. broken wires either individually or in groups ,rope damage caused by lightning , squeezing, nicking etc. are local in nature and can not therefore be detected by measuring cross sectional area.. The main application of cross sectional area measurement would appear to be the determination of loss of cross section of largely uniform material wear that is generally difficult to quantify.

Determination of absolute metallic area of a rope

Certain conditions occur during the service life of a rope, which causes rope deterioration at different rates over different lengths. For example in an endless haulage rope deterioration may occur due to wear causing the best section to show a loss of metallic area. Corrosion may occur on a friction hoist balance rope, whereas both erosion and wear may occur on a slope hoist rope in which the ends have been reversed to place the worn and corroded portion on the rope from the rear end to the drum.

Under these conditions NDT may estimate the true loss of metallic area because of the reference point on the rope assumed to be at 100% is not true. Further, incorrect assumption of rope construction, determination of actual metallic area (47 to 49%in case of stranded ropes and 83 to 85% in case of full locked coil ropes),metallic influence caused due to objects near the test head, influence of radio frequency, electromagnetic signals inaccuracy in strip chart recording , estimation of true LMA caused by instrument averaging as well due to metallic debris over the rope length correlating loss in metallic area by localized flaws and misinterpretation of test results are the common errors committed by unskilled personnel conducting NDT.

Finally, in conducting NDT of wire rope averaging the length of the instrument is the most important factor to understand and consider. Misapplication can also cause a serious under estimation or over estimation of the LMA. One who conducts NDT of ropes should analyze rope samples from retired ropes to acquire a good understanding of his NDT instruments and the strip chart indications which would be useful information for a preventive maintenance program.

Rope discard criteria adopted by different countries

O.I.T.A.F (International organization for ropeway transport) for haulage /carrying rope

LF – 8 broken wires in 40 times the diameter of the ropes

LMA – 10% (max) reduction. In the stretched condition irrespective of the conditions the rope must be removed off the installation after 8 years.

Canadian Specification – CAN /CSA – Z98 – M91- passengers rope ways rope retirement criteria by NDT.

Table 2: The maximum allowable number of broken wires in one rope lay.

| Rope type | Maximum number of permissible broken wires | |

| In one strand | In all strand | |

| 6X7 | 2 | 4 |

| 6X19 | 4 | 6 |

| 6X37 | 6 | 10 |

Table 3: Maximum permissible cross sectional area reduction by NDT (LMA).

| Haulage rope (All types) | 25% in 500x d length of the rope or 8% in

40xd or 6% in 6xd |

| Track ropes

(Full locked coil) | 10% in 200Xd or 5% in 30Xd |

Table 4: International Standard/British Specification Regulations

| Rope construction

** F = Filler | Maximum No. of Broken Wires | ||

| ISO 4309 | BS 6570 | ||

| 6xd | 10xd | 10xd | |

| 6 X 7 | 2 | 3 | 2 |

| 6 X 19 | 5 | 6 | 5 |

| 6 X 19 | 3 | 4 | 5 |

| 6 X 19S*/ 6 X 25/ 6 X 19F** | 5 | 6 | 7 |

| 8 X 19F** | 6 | 8 | 10 |

| 6 X 36 | 7 | 9 | 10 |

| 6 X 37 | 10 | 13 | 11 |

| 6 X 41 | 9 | 11 | 12 |

Mine winding haulage rope

- Code of federal regulations – Mineral resources – Recommends that atleast once in every 6 months non destructive test shall be conducted on the active length of rope. Retirement criteria under clause 57.19024 stipulates that the maximum number of broken wires within a rope lay length excluding filler wire should not exceed the total number of wire or 15%of the total number of wires within any strand .

- Loss of metallic area should not exceed 10% of the actual metallic area.

- Regulations for mines and mining plants – Occupational Health and safety branch – Ontario regulation suggests rope replacement when broken wires exceeds 5% of the total in one lay length excluding filler wire as well a loss of 10% loss in cross section area is observed over the active rope length.

Mine winding and haulage ropes

Bureau Of Indian Standard specifications – Code of practice for the selection, installations and maintenance of the wire ropes (IS: 3973/1984) recommends rope retirements when the rope approaches a loss in breaking strength to the tune of 1/10th of the original strength due to localized/distributed flaws.

Further, IS : 5228/1969,IS : 5229/1969 and IS : 5230/1969 – are code of practice for construction of continuous to and fro movement mono-cable ropeways with fixed grips intended for transportation of passengers ,Code of practice for the construction of continuous to and fro movement mono-cable ropeways with automatic grips intended for transportation for passengers, Code of practice for the construction of continuous to and fro movement bi-cable ropeways intended for transportation of passengers respectively .

Although it recommends that before the wire ropes are put into service ,they shall be checked by suitable non destructive means ,but they do not incorporate the extent by which the rope is to be discarded due to localized /distributed flaws. Even the first revision Doc: HM6 (0281) does not incorporate any changes.

Conclusions

Recent statistics analysis of over 8000 laboratory and field test record reveals that:

Roughly 10% of all ropes showed over 15% strength loss as compared to the initial breaking strength, more than 2% of the rope had lost over 30% of the initial breaking strength. In other words while still in service, 10% of all ropes were in and unacceptable and potentially hazardous conditions and 2 %of the ropes were in an extremely dangerous condition.

Conversely, more than 70%of all ropes in the sample were removed from service while still exhibiting near initial breaking strength. These findings raise some serious questions as to timeliness of rope removal, one way or the other. A program of regularly scheduled NDT’s typically at 6 months interval are of particular value for safe and extended rope usage.

Presently dual function wire rope testers with improved computer technology for traditional measurement of loss of metallic area, local faults and new total change of metallic area are available in market. From the different discard criteria, it can be defined and understood unambiguously in dimension and by number – reduction in cross section and the number of broken wire.

So far as the BIS standard are concerned , although non-destructive investigation in aerial ropeway haulage/carrying /track ropes and mining haulage ropes (specially in friction winders)is essential since there is no other means to evaluate/assess the rope condition while they are in service. The discard criteria is insignificant since the rope evaluation by assessing loss in breaking strength is a dangerously deceptive criterion for continued service of a rope ,which the wire rope community now recognizes to be unsuitable as a measure of the rope condition.

Acknowledgment

The authors are thankful to the Director, Central Mining Research Institute, Dhanbad for his kind approval to publish this paper.

References

- Comparison of the discard criteria in the regulations of different countries – W. Beck, University of Stuttgart (D).

- Procedure and results of electromagnetic testing of mine hoist ropes using the LMA – TEST™ instruments- D.N.Poffenroth,U.S.Department of Labour.

- New methods of measuring the cross section of ropes – A. Haller,EMPA (Swiss Federal Laboratories for material testing and research laboratories)Dupendorf.

- Electromagnetic testing – A reliable method for the inspection of wire ropes in service – H.R.Weischedel and R.P.Ramsey.

- In – service inspection of wire ropes: State of the art – HR.Weisched.