Thermography in Non-Destructive Testing (NDT)

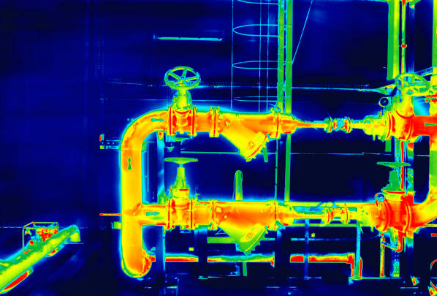

Thermography is a non-destructive testing method that uses infrared cameras to detect and analyze temperature variations in an object or material. This technology can be used to identify potential issues or defects in a wide range of industrial and commercial applications, including electrical systems, mechanical equipment, and buildings.

What is Thermography in NDT?

Thermography is a non-destructive testing method that uses infrared cameras to detect and analyze temperature variations in an object or material. This technology can be used to identify potential issues or defects in a wide range of industrial and commercial applications, including electrical systems, mechanical equipment, and buildings. Thermography can be used to detect issues such as insulation defects, electrical hot spots, and mechanical problems, which can prevent costly repairs and downtime.

Advantages of Thermography in NDT

Thermography is a non-invasive method that does not damage the object or material being tested. It allows for quick and easy detection of potential issues, without the need for disassembly or shutdown of equipment. It can be used to inspect large areas and complex systems, providing a comprehensive view of the entire system. Thermography can be used in a variety of environments and temperatures, making it a versatile testing method.

Applications

Thermography can be used to detect and analyze a wide range of issues in industrial and commercial applications. Some of the most common applications include:

- Electrical systems: thermography can be used to detect issues such as loose connections, faulty equipment, and insulation defects.

- Mechanical equipment: thermography can be used to detect issues such as bearing wear, leaks, and overheating.

- Buildings: thermography can be used to detect issues such as insulation defects, air leaks, and moisture intrusion.

- Thermography is also used in the medical field to detect issues such as breast cancer, and in wildlife conservation to detect issues such as animal migration patterns.

How does it work?

Thermography uses infrared cameras to capture thermal images of an object or material. These images are then analyzed to detect and identify temperature variations, which can indicate potential issues or defects. The camera used in thermography detects infrared radiation, which is emitted by all objects above absolute zero (-273°C). The infrared radiation is converted into an electrical current, which is then processed to create a thermal image.

Training and Certification for Thermography in NDT

Thermography is a specialized field and requires proper training and certification to ensure accurate and reliable results. There are several organizations that offer training and certification programs for thermographers, such as the Infrared Training Center and the American Society for Nondestructive Testing. These programs cover topics such as infrared camera operation, thermographic image analysis, and safety procedures. Properly trained and certified thermographers are able to produce accurate and reliable results, which can help prevent costly repairs and downtime.

In conclusion, thermography is a valuable non-destructive testing method that can be used to detect and analyze a wide range of issues in industrial and commercial applications. It is a non-invasive, quick and easy method that can save companies a lot of money and downtime by identifying potential issues early on. With proper training and certification, thermography can be a reliable and accurate tool in the arsenal of non-destructive testing methodologies.

For more information regarding thermography, visit our group or thermography forum section.

Responses