Acoustic Emission (AE)

Welcome to [NDT Inspection Portal]’s acoustic emission (AE) group, a place for professionals to... View more

acoustic speed of liquid metal

acoustic speed of liquid metal

lock length under the bath. The interface between melted/solid titanium

: should give the reflection, which could be used to measure the unmelted titanium length.

: If the measurement is performed from the very begining, when all the titanium is not melted,

: latter measurement can be subtracted from initial one.

: Liquid titanium could change its volume, so the optical measurement can be done from the laser

: beam side. In this case laser beam might be employed to do that.

: One also has to be aware of raising temperature effect on solid titanium ultrasound speed.

: If there is no liquid in the ultrasound path from transducer to melted/solid titanium interface,

: dual wave transducer can be used. Interesting choice are Zinc oxide sputtered transducers.

: If ZnO crystals are sputtered at some agle, such transducer is producing longitudinal and share

: waves at the same time. In such case the temperature effect can be eliminated. It will also

: produce a good acoustical coupling. But… How much of temperature these transducers culd withstand?

: In case the temperature at measurement point is quite low, it couls be the case.

: I believe there should be one more case considered. The bath will be of a hemisphere shape.

: In case wide beam transducer is ised, there will be a distortion in bath bottom depth measurement.

: I think the transducer should be foccused, with focal point located at liquid-gas interface.

: In case there will be penetration of melted bath deeper to titanium block, the position of surface

: might change, so the focal spot length should be under consideration too.

: All said concerns the pulse propagation in the liquid titanium bath measurements. The transit-time

: resonanse, tone-burst phase match and etc techniques can be considered.

: There is one more idea. The ultrasonic beam, after passing the liquid titanium bath, can create

: the waves on the melted titanium surface. By laser interferometry measurements (might be shearography

: can be suitable too), the spatial distance between two peaks can be measured. The wavelength can be

: calculated in such way…: Linas Svilainis

The cooled coupling plate is planned to make of an AlMg-alloy.

The maximum temperature at the point of transducer contact shall

be about 373 K. At the back site of the titanium plate the

temperature raises to about 873 K, but very localized beneath

the melting bath. The liquid titatium is in fact a pool on top

of the solid titanium, but a pool wandering along the surface.

While the transducer position is fixed beneath the titanium, the

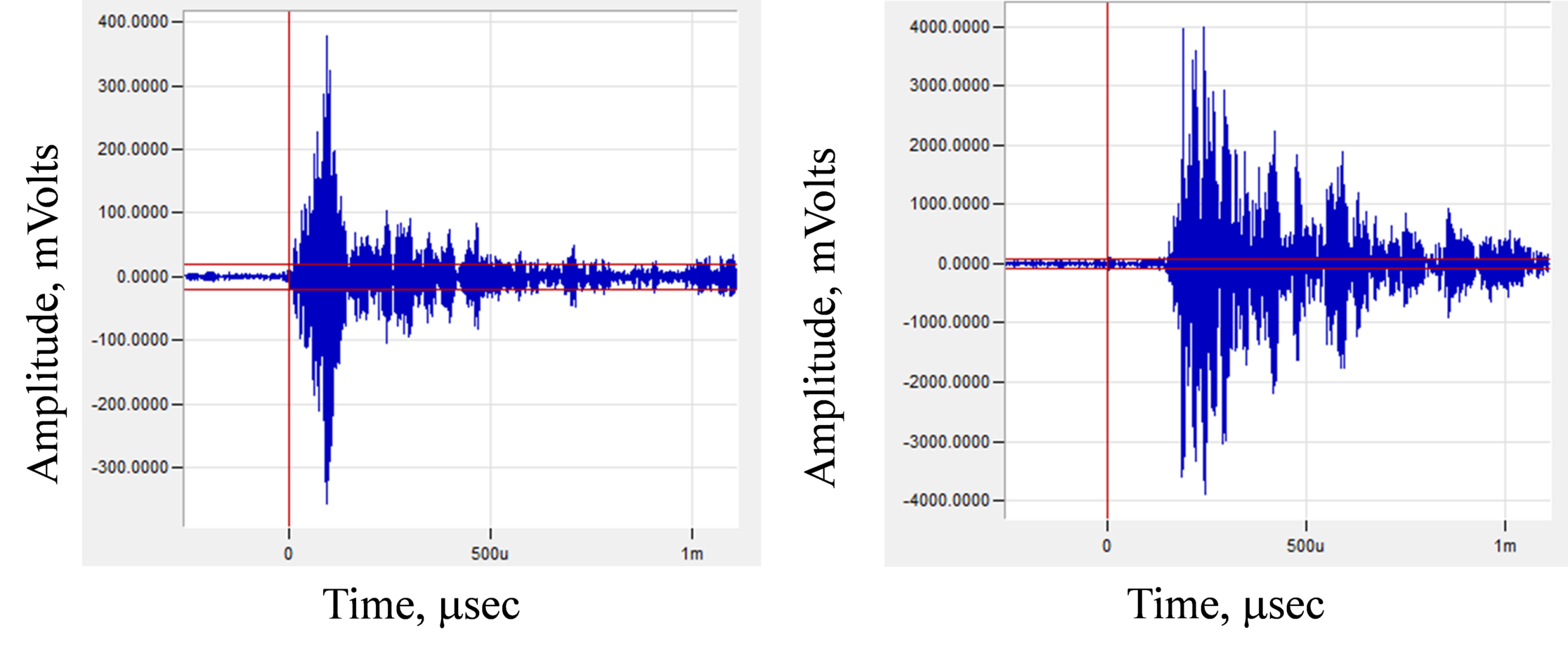

liquid pool moves through the sound field. The method suggested

by Linas for measuring the melting depth should be possible, if the

echos are measurable. The second way for measuring the melting depth

is cutting and polishing the specimen after processing. The position of

transducer and specimen, the track speed and the moment when the

measuring starts are exactly known. In this way it should be possible

to determine the melting depth too.

Log in to reply.