Destructive Testing

Public Destructive Testing

Active 5 months ago

Welcome to [NDT Inspection Portal]’s destructive testing group, a place for professionals to connect... View more

Public Destructive Testing

Group Description

Welcome to [NDT Inspection Portal]’s destructive testing group, a place for professionals to connect and discuss the latest techniques and technologies in destructive testing.

Destructive testing is a type of testing that involves subjecting a component or material to various stresses and loads in order to evaluate its properties and performance. It is typically used to determine the strength, durability, and reliability of a component or material under extreme conditions.

Destructive testing can involve a range of methods and techniques, including tensile testing, impact testing, and fatigue testing. These methods are used to evaluate the performance of a component or material under various loads and conditions and to identify any potential issues or defects that may affect its performance. Our member group offers a platform for sharing knowledge and best practices on destructive testing and its applications in various industries.

Join our community of experts from around the world and be a part of the conversation on advancing the practice of destructive testing. Whether you are new to destructive testing or an experienced professional, you’ll find valuable resources and a welcoming community in our group.

What are 5 destructive tests used in fiber analysis?

What are 5 destructive tests used in fiber analysis?

Posted by thomas on 14/10/2021 at 3:13 pmMost common are destructive tests, such as stress, fatigue and micro sectioning tests. There are also methods that allow non-destructive testing (NDT), so the material can be still be used after testing. Common methods are ultrasonic, X-ray, HF Eddy Current, Radio Wave testing or thermography.

nde replied 2 years, 9 months ago 2 Members · 1 Reply- 1 Reply

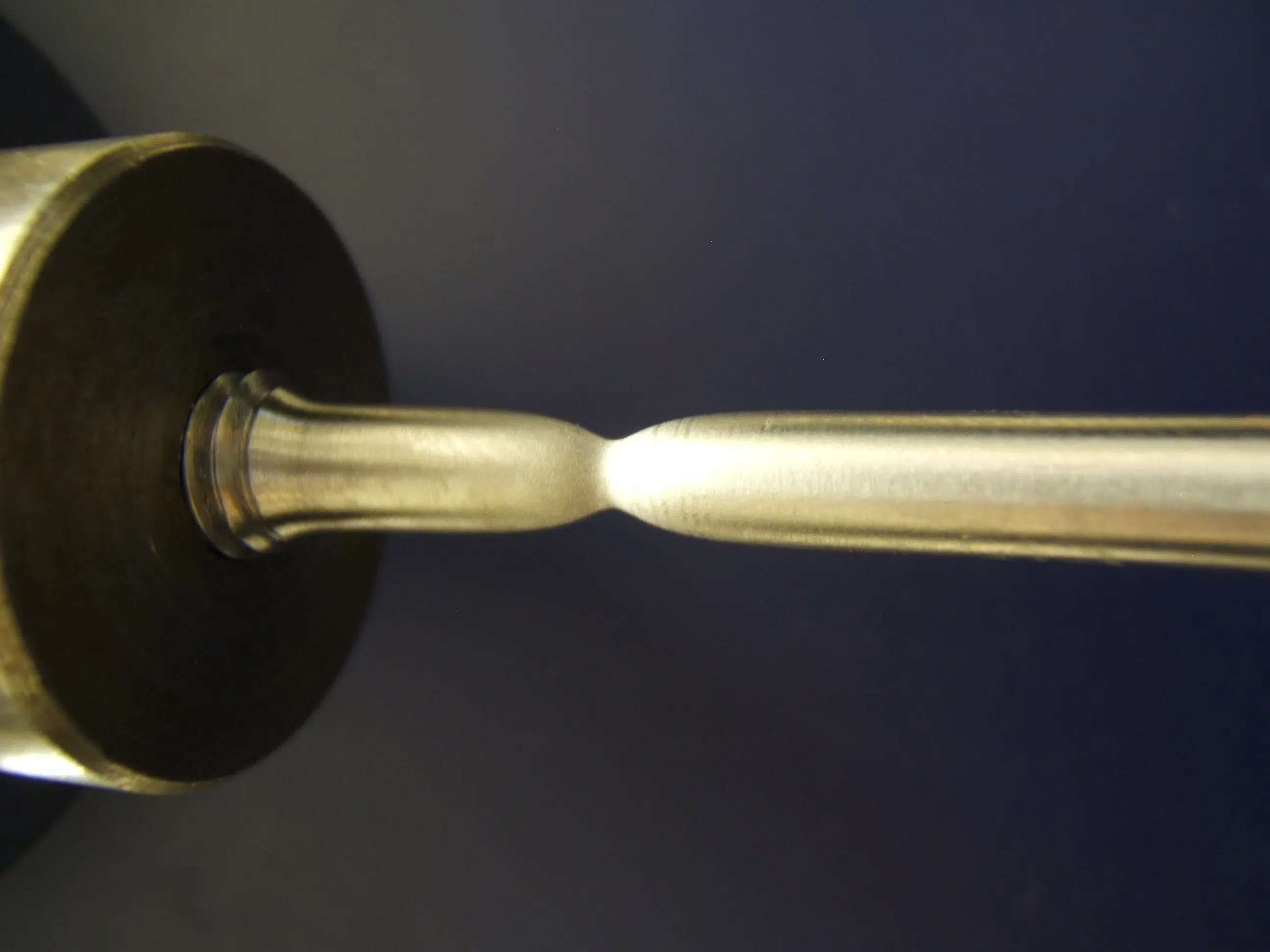

Tensile Testing: This test involves pulling a fiber to its breaking point to determine its tensile strength and elongation at break. The fiber is secured between two grips and subjected to a controlled pulling force until it breaks. Tensile testing is used to determine the fiber’s strength and its ability to withstand strain.

Abrasion Testing: This test involves rubbing a fiber against a rough surface to determine its abrasion resistance. The fiber is rubbed against a specified surface with a specified weight and force, and the amount of fiber loss is measured. Abrasion testing is used to determine the durability of a fiber.

Flexural Testing: This test involves bending a fiber to determine its flexural strength and modulus of elasticity. The fiber is supported at two points and subjected to a bending force until it breaks. Flexural testing is used to determine the fiber’s stiffness and flexibility.

Impact Testing: This test involves dropping a weight onto a fiber to determine its impact strength. The fiber is clamped to a support and a weight is dropped onto it from a specified height. The amount of energy absorbed by the fiber is measured. Impact testing is used to determine the fiber’s ability to withstand sudden shocks.

Compression Testing: This test involves compressing a fiber to determine its compressive strength and modulus of elasticity. The fiber is placed between two plates and subjected to a compressive force until it buckles. Compression testing is used to determine the fiber’s ability to withstand compressive forces.

Log in to reply.