Heat Treatment (PWHT)

Public Heat Treatment

Active 10 months ago

Welcome to [NDT Inspection Portal]’s heat treatment (PWHT) group, a place for professionals to connect... View more

Public Heat Treatment

Group Description

Welcome to [NDT Inspection Portal]’s heat treatment (PWHT) group, a place for professionals to connect and discuss the latest techniques and technologies in heat treatment.

Heat treatment is a process used to alter the physical and mechanical properties of materials through the application of heat and cooling. It is often used to improve the strength, hardness, ductility, and other properties of materials and is an important aspect of ensuring the quality and performance of products and structures in various industries.

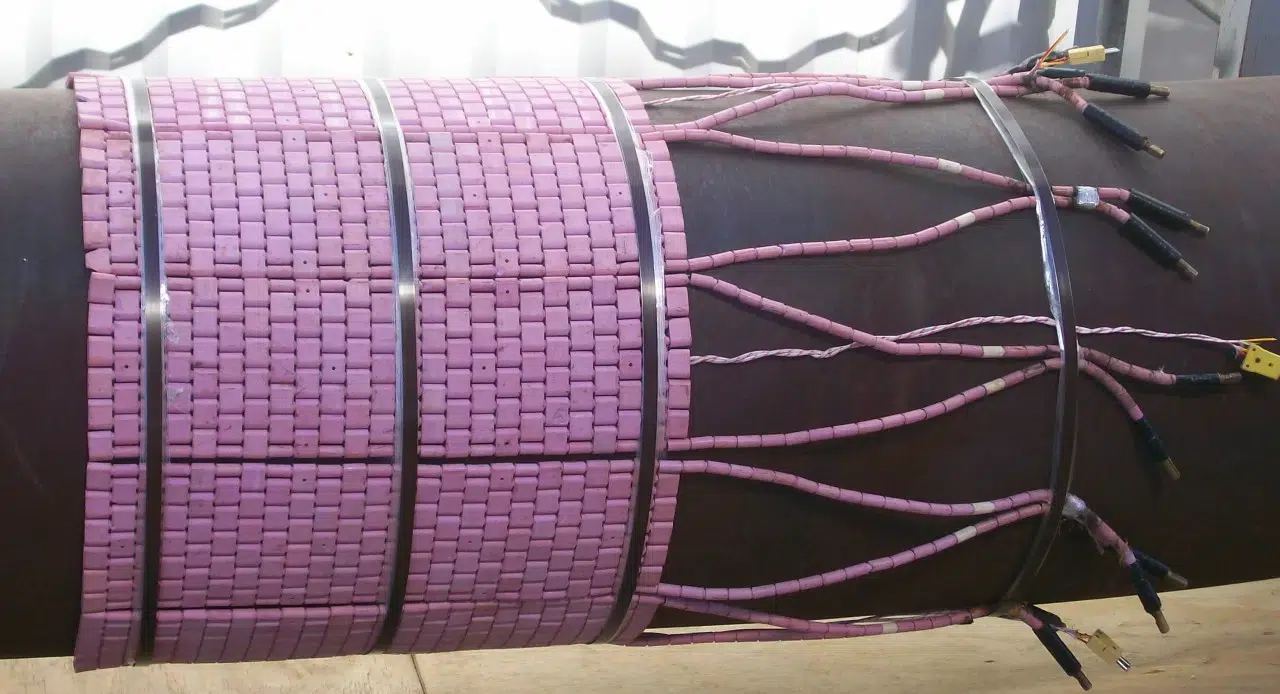

Post-weld heat treatment (PWHT) is a specific type of heat treatment that is applied to welded joints and components to improve their properties and performance. It involves the application of heat to the welded joint or component after welding is complete, followed by a controlled cooling process. PWHT is often used to reduce residual stress and improve the toughness and corrosion resistance of welded joints and components.

Our member group offers a platform for sharing knowledge and best practices on heat treatment and its applications in various industries. Join our community of experts from around the world and be a part of the conversation on advancing the practice of heat treatment and its applications in the field of NDT and inspection. Whether you are new to heat treatment or an experienced professional, you’ll find valuable resources and a welcoming community in our group.

Reply To: NDT before and after PWHT low carbon steel

-

his was the subject of a recent discussion here and I can make the following comments, which are my personal views others may add or disagree:

1. In our case PWHT on carbon steel is generally service related e.g. Carbon steel pipe work in Amine and Caustic service.

2. The code says that NDT should be performed after welding and as heat treatment is a part of the welding technology, it should be performed after heat treatment.

3. Many sites will want to perform NDT before heat treatment as this saves the time and money of having to repair welds and again perform heat treatment on the repair. As the owner we are willing for the contractor to do the NDT before heat treatment, but at his own cost.

4. The NDT carried out before heat treatment should be the same as the NDT carried out after heat treatment. Generally the NDT before heat treatment has been radiography, but as the owner we have substituted this for UT after heat treatment. The theory being, that the only repairable defects likely after heat treatment (if this has not been performed correctly) is cracking and the preferred method for crack detection in this instance would be UT.