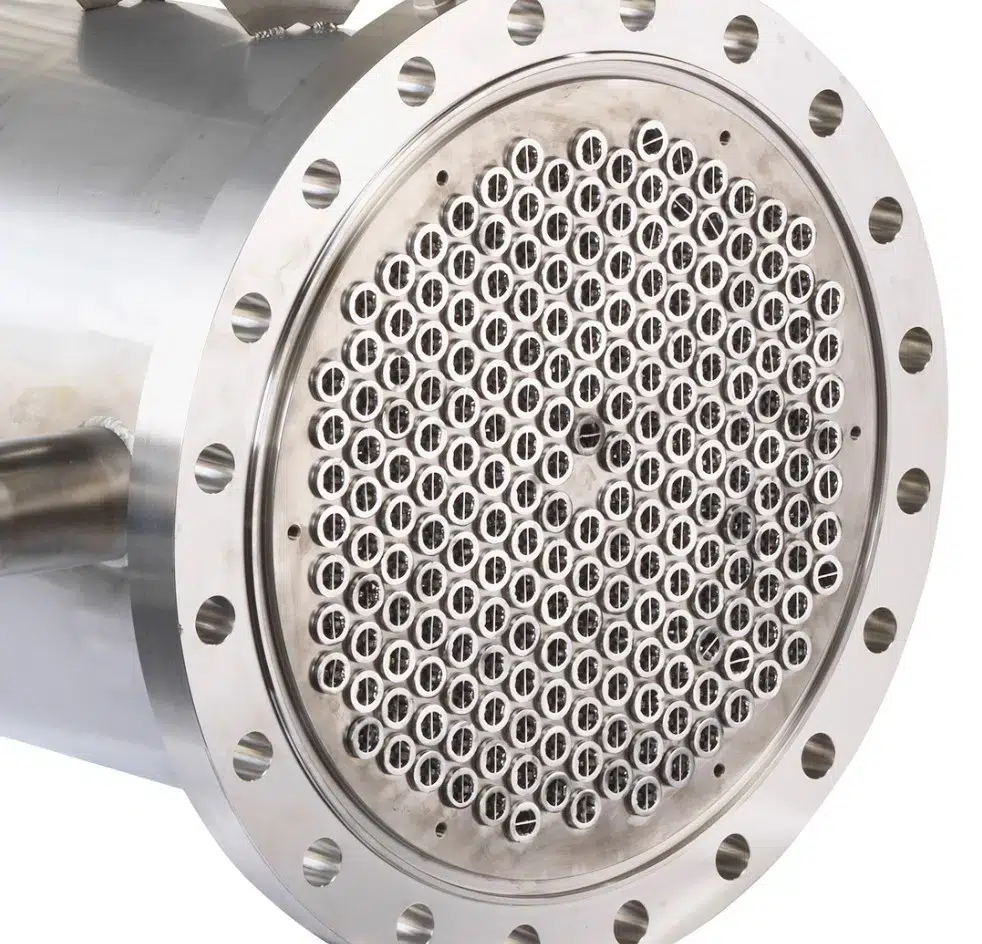

Internal Rotary Inspection (IRIS)

Welcome to [NDT Inspection Portal]’s internal rotary inspection (IRIS) group, a place for professionals... View more

IRIS is an ultrasonic technique used for the inspection of a wide range

IRIS is an ultrasonic technique used for the inspection of a wide range

IRIS is an ultrasonic technique used for the inspection of a

wide range of materials, including both non-ferromagnetic and

ferromagnetic tubing.

• Allows for the detection and sizing of wall loss as a result of corrosion, erosion, tube-to-tube wear, pitting, fretting,

cracking and baffle cuts.

• Focused ultrasonic probe and a rotating mirror to produce

a helical scan.

• Ultrasound is reflected from the tube ID and OD and the

time difference is used to calculate the thickness.

• IRIS is a great backup and verification tool for the other

tube inspection techniques

• IRIS data to be presented as a B, C, or D-scan image.

Sorry, there were no replies found.

Log in to reply.