Phased Array Ultrasonics (PAUT)

Phased array ultrasonics is a highly advanced and effective method for non-destructive testing. Using high-frequency sound waves and electronically controlled ultrasonic transducers, it allows for the rapid and accurate inspection of materials and components to detect flaws, measure thickness, and evaluate the integrity of structures.

This versatile technique is widely used in a variety of industries, including aerospace, automotive, power generation, and oil and gas, to ensure the safety and reliability of products and systems.

In this article, we will explore the principles of phased array ultrasonics and its many benefits, as well as the challenges and applications of this powerful inspection tool.

What is Phased Array Ultrasonics (PAUT)

Phased array ultrasonics is a non-destructive testing technique that uses high-frequency sound waves to inspect the internal structure of materials and components.

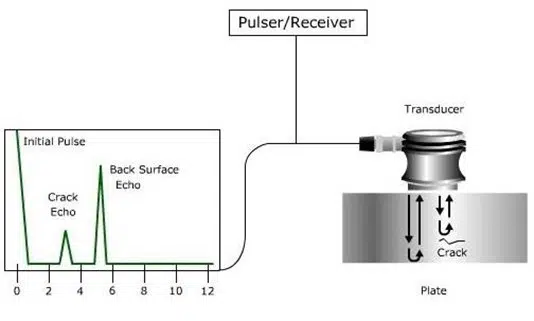

It works by generating and transmitting ultrasonic waves through a material using a specialized probe or transducer.

The waves are reflected back when they encounter changes in the material’s properties or structure, such as a flaw or interface between two different materials. By analyzing the reflections, it is possible to determine the location, size, and type of the feature being inspected.

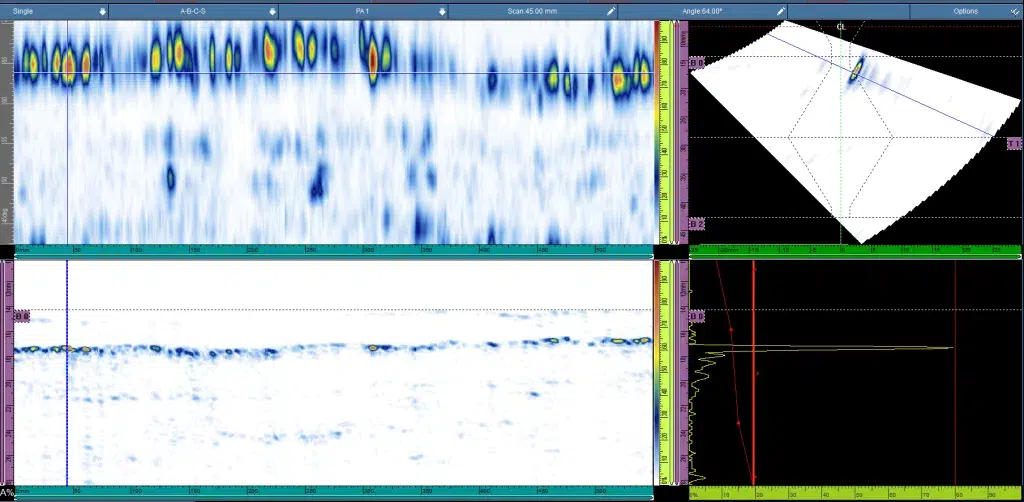

In a phased array ultrasonic system, multiple transducers are used in combination to create a focused beam of sound that can be electronically controlled to scan a specific area.

By adjusting the phase and amplitude of the individual transducer signals, the beam can be steered and focused to different depths and angles within the material.

This enables phased array ultrasonics to perform inspections quickly and accurately, with a high level of detail and resolution.

Advantages of Phased Array Ultrasonics

Phased array ultrasonics offers several key advantages over other non-destructive testing techniques:

- Speed: By using multiple transducers that can be electronically controlled, phased array ultrasonics can scan a large area in a short amount of time. This makes it an efficient and cost-effective method for inspecting a wide range of materials and components.

- Accuracy: Phased array ultrasonics provides a high level of detail and resolution, making it possible to detect small flaws and measure thickness accurately. It is also capable of inspecting materials with complex geometries and identifying flaws at different depths within the material.

- Versatility: Phased array ultrasonics can be used to inspect a wide range of materials, including metals, composites, and ceramics, and can be applied to a variety of shapes and sizes, including flat surfaces, curved surfaces, and complex geometries.

- Safety: Phased array ultrasonics is a non-destructive testing technique, which means it does not damage the material being inspected. This makes it an ideal choice for inspecting critical components and structures that cannot be damaged during the inspection process.

Applications

Phased array ultrasonics is used in a variety of industries to inspect a wide range of materials and components. Some common applications include:

- Aerospace: Phased array ultrasonics is used to inspect aircraft structures, including fuselage panels, wing spars, and engine components, to detect cracks and other flaws that could affect the safety and performance of the aircraft.

- Automotive: Phased array ultrasonics is used to inspect car and truck parts, including engine blocks, cylinder heads, and transmission gears, to ensure their quality and reliability.

- Power generation: Phased array ultrasonics is used to inspect power plant components, including boilers, pipes, and turbine blades, to identify and address potential issues before they cause failures or accidents.

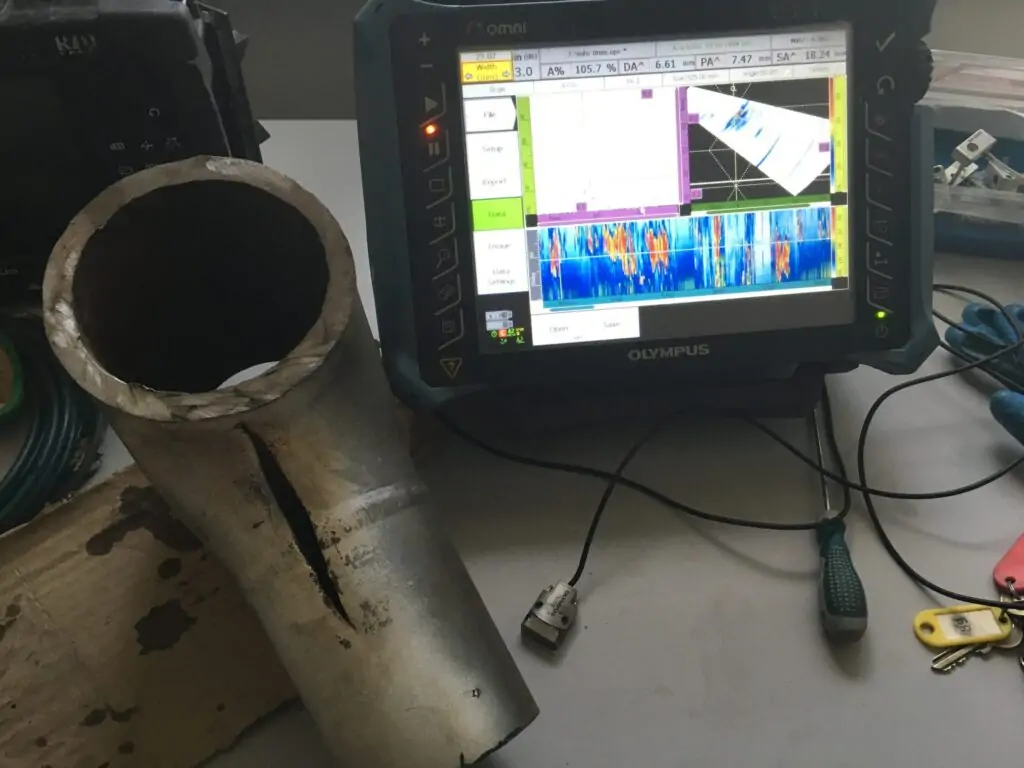

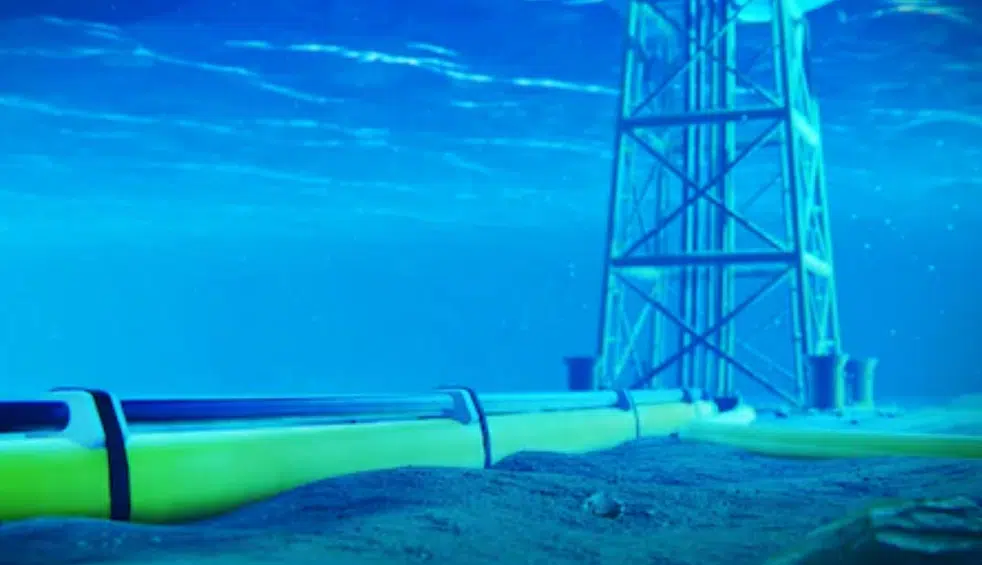

- Oil and gas: Phased array ultrasonics is used to inspect pipelines, tanks, and other oil and gas industry equipment to detect corrosion and other damage that could compromise their integrity.

These are just a few examples of the many industries and applications where phased array ultrasonics is used to ensure the safety and reliability of products and systems.

Challenges of using PAUT

While phased array ultrasonics offers many advantages over other non-destructive testing techniques, there are also some challenges to using it.

One of the main challenges is the need for skilled technicians to operate the equipment. Proper training and experience are necessary to ensure that the inspection is performed accurately and safely.

Another challenge is that phased array ultrasonics is not suitable for all materials. It is most effective on materials with good ultrasonic wave transmission properties, such as metals and certain composites.

Materials that are too porous or too dense, or those with large internal features, may not be suitable for phased array ultrasonics inspection.

Additionally, the cost of phased array ultrasonics equipment and training can be a factor for some organizations. However, the benefits of using phased array ultrasonics far outweigh the costs, as it enables manufacturers and service providers to identify and address potential issues before they become major problems.

Summary

Phased array ultrasonics is a powerful tool for non-destructive testing that provides fast, accurate, and versatile inspection capabilities. Its ability to detect flaws and evaluate the integrity of materials and components makes it an essential tool in a variety of industries, helping to ensure the safety and reliability of products and systems.

While the use of phased array ultrasonics requires skilled technicians and may not be suitable for all materials, the benefits of this technique far outweigh the challenges.

By using phased array ultrasonics, organizations can identify and address potential issues before they become major problems, improving the reliability and performance of their products and systems.

If you are interested in learning more about phased array ultrasonics or connecting with other professionals in the field, consider joining PAUT group and forum section on the NDT Inspect portal.

This online community is a great resource for staying up-to-date on the latest developments in non-destructive testing, sharing knowledge and experiences, and networking with other professionals in the industry.

Whether you are new to phased array ultrasonics or an experienced practitioner, PAUT group and forum on the NDT Inspect portal is an excellent resource for staying connected and informed.

Responses