Corrosion Mapping (CM)

Welcome to [NDT Inspection Portal]’s corrosion mapping group, a place for NDT professionals to connect... View more

Stress Corrosion Cracking

-

Stress Corrosion Cracking

Dear Experts,

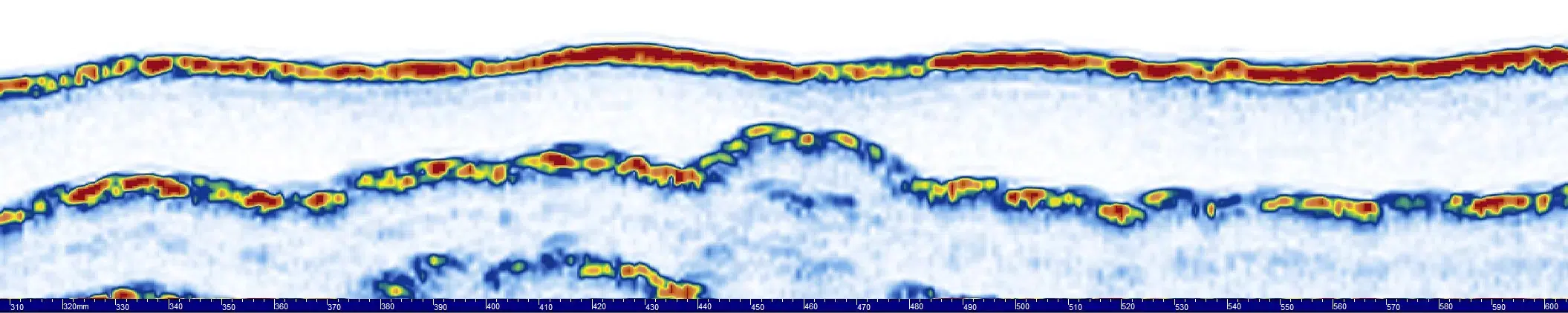

My next R&D project is to investigate different NDE method’s capability to accurately locate and size Stress Corrosion Cracks. Here is an example of how SCC can be seen by the EWI Computed Tomography system.

Let me know if you want to collaborate on this study. I plan to use Thermography, ET, PAUT, and FMC/TFM.

Please share your success stories on SCC detection and evaluation, as NDT methods, techniques, equipment, sensors…

Log in to reply.