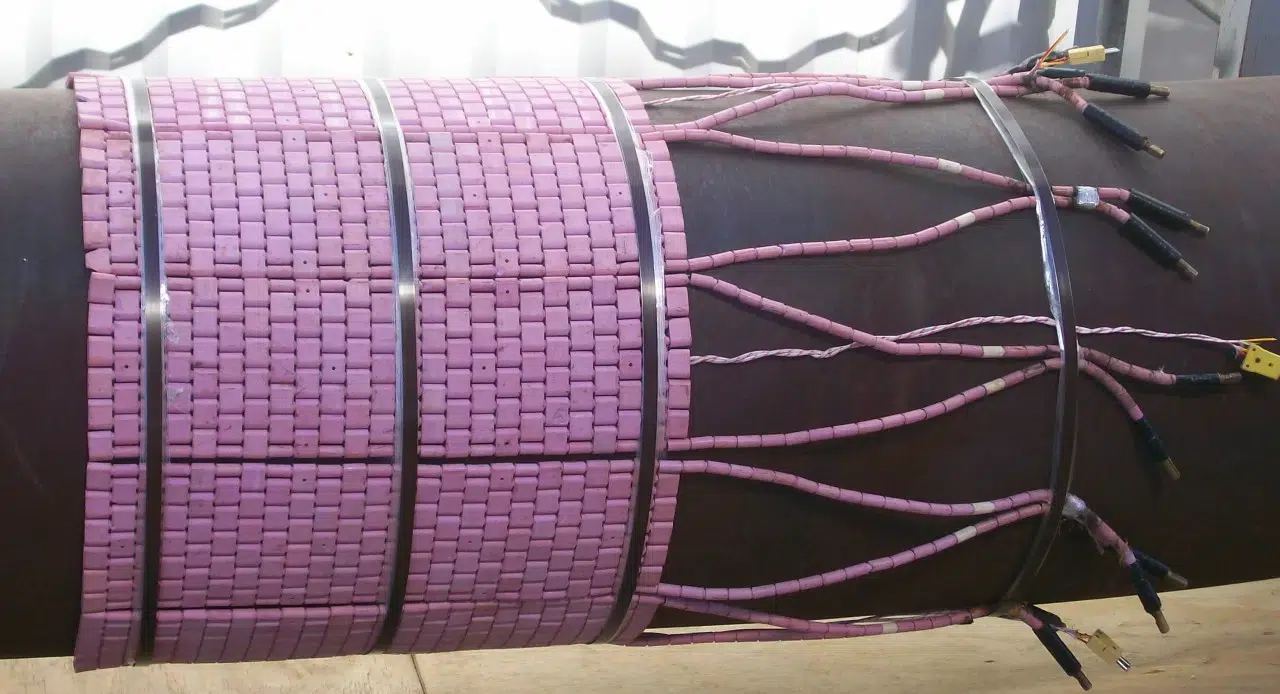

Heat Treatment (PWHT)

Welcome to [NDT Inspection Portal]’s heat treatment (PWHT) group, a place for professionals to connect... View more

NDT before and after PWHT low carbon steel

-

NDT before and after PWHT low carbon steel

PWHT is approx 1 hour @ 650 deg Celsius on P1 (low carbon) steels. Is there a Code requirement (ASME/ANSI/API/EN/SNiP) that such NDT MUST be done after PWHT?

What do forum members think of a suggestion for NDT before PWHT only. If all unacceptable RT indications are repaired prior to stress relief (1 hour @ 650 deg), is there any likelihood/possibility of stress relief of P1 materials causing metallurgical problems or acceptable/undetected indications to open up which may then be detected by RT and be cause for rejection. Is the latter realistic or is NDT after PWHT on low carbon materials just a convention.

Thanks in advance for your comments.

Log in to reply.