Pipeline X-Ray Inspection

Public Pipeline

Active 5 months ago

Welcome to [NDT Inspection Portal]’s pipeline X-ray inspection group, a place for professionals to... View more

Public Pipeline

Group Description

Welcome to [NDT Inspection Portal]’s pipeline X-ray inspection group, a place for professionals to connect and discuss the latest techniques and technologies in pipeline X-ray inspection.

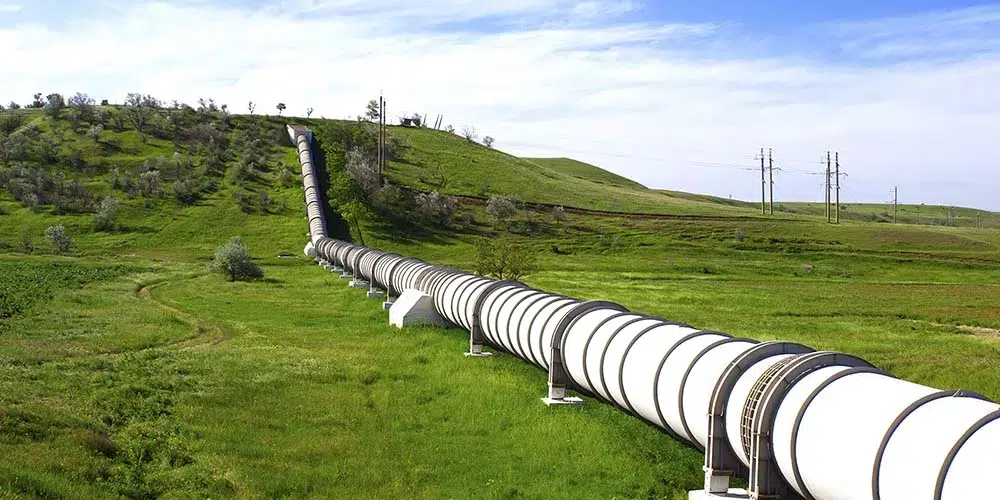

Pipeline X-ray inspection is a specialized technique used to evaluate the condition and performance of pipelines using X-ray technology. It is an important aspect of ensuring the integrity and reliability of pipelines in various industries, including oil and gas, water and wastewater, and transportation.

Pipeline X-ray inspection involves the use of specialized X-ray equipment and techniques to produce detailed images of the internal structure of pipelines. These images can be used to identify any potential issues or defects, such as cracks, corrosion, or weld defects, and to evaluate the condition of the pipeline. Pipeline X-ray inspection is often used in conjunction with other non-destructive testing (NDT) methods, such as ultrasonic testing and magnetic particle inspection, to provide a comprehensive evaluation of the pipeline.

Our member group offers a platform for sharing knowledge and best practices on pipeline X-ray inspection and its applications in various industries. Join our community of experts from around the world and be a part of the conversation on advancing the practice of pipeline X-ray inspection and its applications in the field of NDT and inspection. Whether you are new to pipeline X-ray inspection or an experienced professional, you’ll find valuable resources and a welcoming community in our group.

Offshore Pipeline X Ray Crawler Image

Offshore Pipeline X Ray Crawler Image

Posted by arsal on 27/11/2021 at 2:23 pmHi,

I am new to offshore and need some advice.

While we are doing pipelaying offshore, normally there is 1/2″ buckle detector cable running through the pipeline. When we use the X-ray crawler to check for the weld quality, how can we ensure this 1/2″ cable will not interfere with the X-Ray image?lucas replied 4 years, 3 months ago 2 Members · 1 Reply- 1 Reply

In truth the Level 3 or Engineer that established your exposure parameters (inspection procedure) should have accounted for this but if he didn’t and you are truly concerned you could try the following (but check with your lead or client before hand to ensure they are ok with it):

For Double wall exposure set your source or camera up as you normally would but then offset your source or camera slightly (no more than 15 degrees) to the right leaving the film or detector plate in its normal position and take the exposure. Then move the source or camera to shoot the same exposure but offset it to the same number of degrees to the left and take a second exposure.

If your 1/2″ cable is laid in the center, or fallen there due to gravity, then doing the offset exposures will allow you to shoot under the cable.

If you have a perfectly perpendicular transverse crack which is tight you may not see it this doing this but you can improve even detecting this by paying very close attention to the grey scale density of your image Unless the transverse crack is exactly in the middle of the material under the cable you should see a density change though it may be slight.

I am not a Level 3 nor do I profess to be an absolute authority or expert in Radiography but as a Level 2 with some experience that is something I might try. Others may have alternate ideas.

Hope this helps. Cheers…

Log in to reply.